Top Welding Methods & Automation Guide for Industrial Metal Parts

Choosing the right welding method is critical in today's manufacturing world. Buyers demand quality, speed, and reliability without exploding costs. In this detailed guide, I cover everything from traditional manual processes like spot, MIG, TIG, and stitch welding to modern robotic systems, cost analysis, real-world examples, and everything you need to decide confidently.

Table of Contents

- Spot Welding vs Tack Welding

- Benefits of MIG, TIG, and Stitch Welding

- Choosing Fuse Welding for Steel and Stainless

- Best Practices in Plug and Seam/Fillet Welding

- Robotic Welding vs Manual: Pros and Cons

- Cost‑Benefit for High‑Volume Projects

- Accuracy Gains with Robotic Systems

- Industry Use Cases: Automotive, Aerospace, Electronics

- FAQs — Common Questions Answered

- Contact Prime for Welding Support

Spot Welding vs Tack Welding

Spot welding uses compressed electrical current at precise points on sheet metal. It creates a permanent bond ideal for repetitive sheet metal parts. Tack welding, on the other hand, places quick short beads to hold assembly components.

Spot welding excels in high-volume thin gauge production. Tack welding shines when alignment and precision matter in thicker assembly builds.

Key Differences

| Aspect | Spot Welding | Tack Welding |

|---|---|---|

| Purpose | Permanent localized joint | Temporary alignment welds |

| Heat Input | High & focused | Low & sparse |

| Thickness | ≤ 6 mm sheet steel | Any thickness, ideal prep step |

| Equipment | Resistance/spot welder | MIG/TIG/stick welding systems |

| Efficiency | Fast for series parts | Moderate, supports precision |

Practical tip: Always clean sheet surfaces and use uniform weld spacing. At Prime, we maintain ±0.3 mm flatness on chassis frames by combining spot welding and tack welding in sequence.

External sources:

- AWS Spot Welding Technical Notes

- Resistance Welding Guidelines

- Steel Sheet Welding Tips – Welding Journal

Benefits of MIG, TIG, and Stitch Welding

Manual welding remains vital, especially for custom parts or mid-volume production. Here's how MIG, TIG, and stitch welding compare:

MIG Welding

- Pros: Fast, easy to automate, excellent for thick steel

- Cons: Produces spatter, reduced finesse on thin material

- Typical Use: Structural brackets, frames, tanks

TIG Welding

- Pros: Extremely clean, precise, ideal for stainless and exotic alloys

- Cons: Slow deposition, requires high skill

- Typical Use: Instrument enclosures, medical equipment housings

Stitch Welding

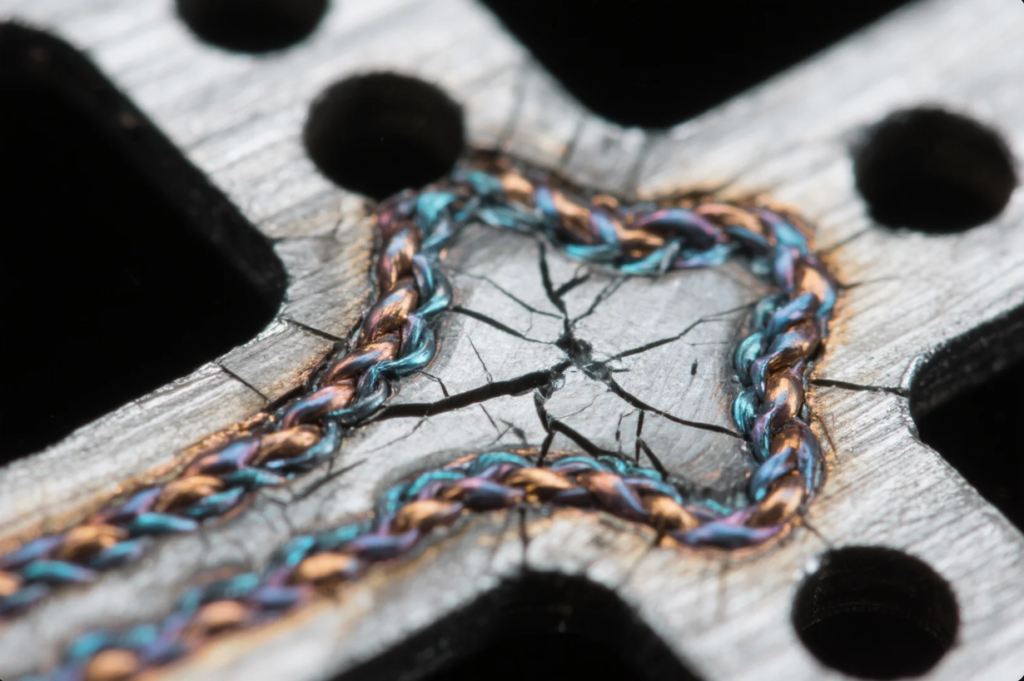

Also known as intermittent welding, stitch welding applies short weld beads along seam paths. It reduces heat distortion significantly.

- Pros: Maintains dimensional accuracy

- Cons: Slower than continuous bead

- Typical Use: HVAC ducts, assembly panels

Performance Comparison Table

| Method | Speed | Finish Quality | Distortion Control | Optimal Application |

|---|---|---|---|---|

| MIG | High | Medium | Low | Thick steel assemblies |

| TIG | Low | Excellent | High | Fine-gauge stainless & exotic |

| Stitch | Medium | High | Excellent | Long seams, sheet welds |

Prime recommendation: Use MIG for heavy parts, TIG for critical finishes, and stitch for distortion control. I often review methods used in aerospace per The Fabricator aerospace reports.

External sources:

- MIG Welding Basics – Miller Electric

- TIG Welding Explained – Lincoln Electric

- Stitch Welding Techniques – Engineering.com

Choosing Fuse Welding for Steel and Stainless

Fuse welding requires precise edge preparation and melts parts directly without filler. This is perfect for stainless or aluminized steel applications where contamination must be avoided.

Use fuse welding when edge purity, corrosion resistance, and joint strength are top priorities.

Critical Considerations

- Edge clearance: ≤ 0.1 mm

- Surface finish: Pickling or grinding required

- Testing: X‑ray and ultrasonic testing recommended

| Requirement | Best Practice |

|---|---|

| Edge Prep | Laser trimming + deburring |

| Fit tolerance | < ±0.1 mm |

| Post-weld testing | Use RT, UT, and dye‑penetrant inspection |

In one project, we used fuse welding on food-grade tanks—maintaining 100% clean stainless interiors. ASME and ISO rules apply: ASME material standards and ISO welding quality.

External sources:

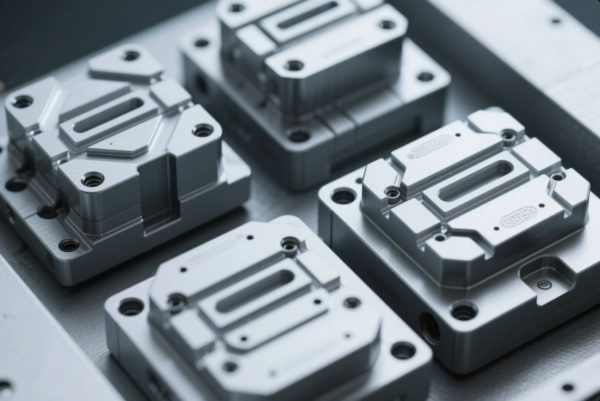

Best Practices in Plug and Seam/Fillet Welding

Plug (hole) welding and seam/fillet welding are essential for assembling overlapping plates. Controlling heat, bead overlap, and weld depth is critical to avoiding structural weakness.

Plug Welding Checklist:

- Hole size: Match to stick wire diameter

- Fill depth: Weld flush or slightly convex

- Grind off scale before next operation

Seam/Fillet Welding Checklist:

- Maintain constant travel speed

- Overlap: 25–30% per pass

- Use balanced tack welds to reduce distortion

We test welded components to ASTM A370 standards—ASTM test methods reference. For QA, we use TWI inspection guidelines.

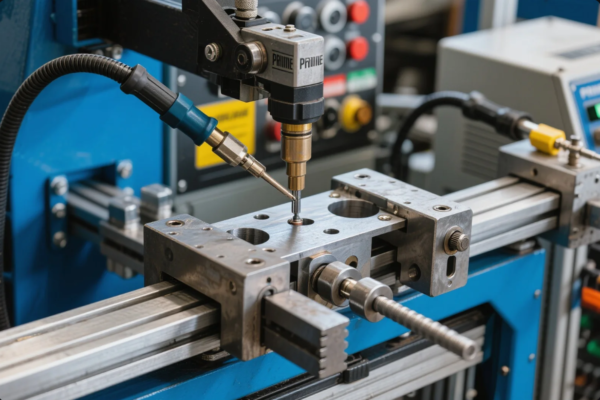

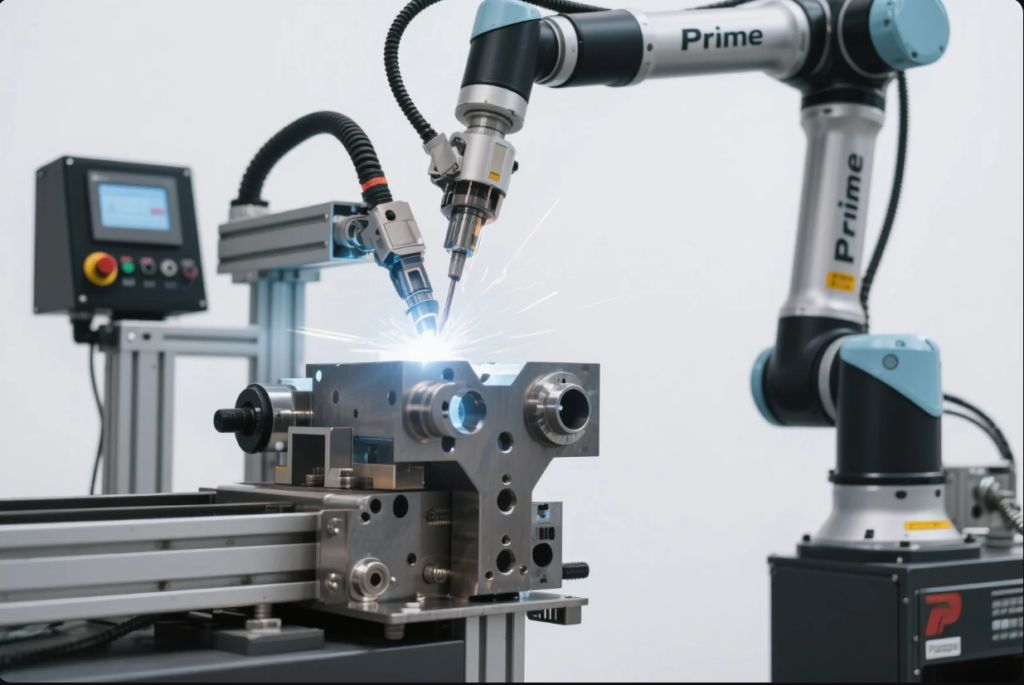

Robotic Welding vs Manual: Pros and Cons

Why Robotic Welding Stands Out

- Consistency: Robots produce identical welds across hundreds of parts

- Speed: 30–50% faster cycle than manual welding

- Cost efficiency: Lower per-part cost with high volume

- Traceability: Full logging for quality audit purposes

Manual Welding Advantages

- Flexibility to adapt to part changes quickly

- Lower initial setup costs (\$2K–5K vs \~\$150K robotic cell)

- Ideal for low to mid-volume and custom jobs

Summary Table

| Feature | Robotic Welding | Manual Welding |

|---|---|---|

| Throughput | Very High | Medium |

| Setup Time | Weeks | Days |

| Flexibility | Limited | High |

| Labor Requirements | 1 tech + programmer | 2–3 welders per shift |

| Quality Control Ease | Automated logs | Manual inspection required |

Prime uses a hybrid model: Robotic cells tackle high-volume jobs, while manual welders handle small custom orders or design iterations.

External sources:

Cost‑Benefit for High‑Volume Projects

The economics of welding change dramatically at scale. When units per year exceed \~10,000, automation becomes essential.

Cost snapshot (1K part example):

- Robotic weld: \~\$0.75/part

- Manual weld: \~\$1.80–2.50/part

Consider scrap rates:

- Robotic <1%

- Manual 3–6%

Add in benefits from reduced rework, scrap, and labor costs—robots quickly pay back within 1–2 years.

More info:

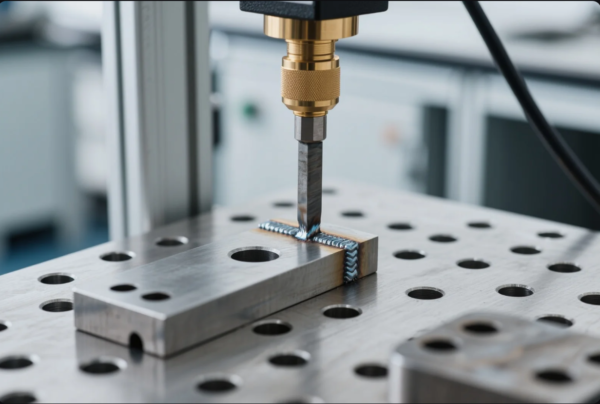

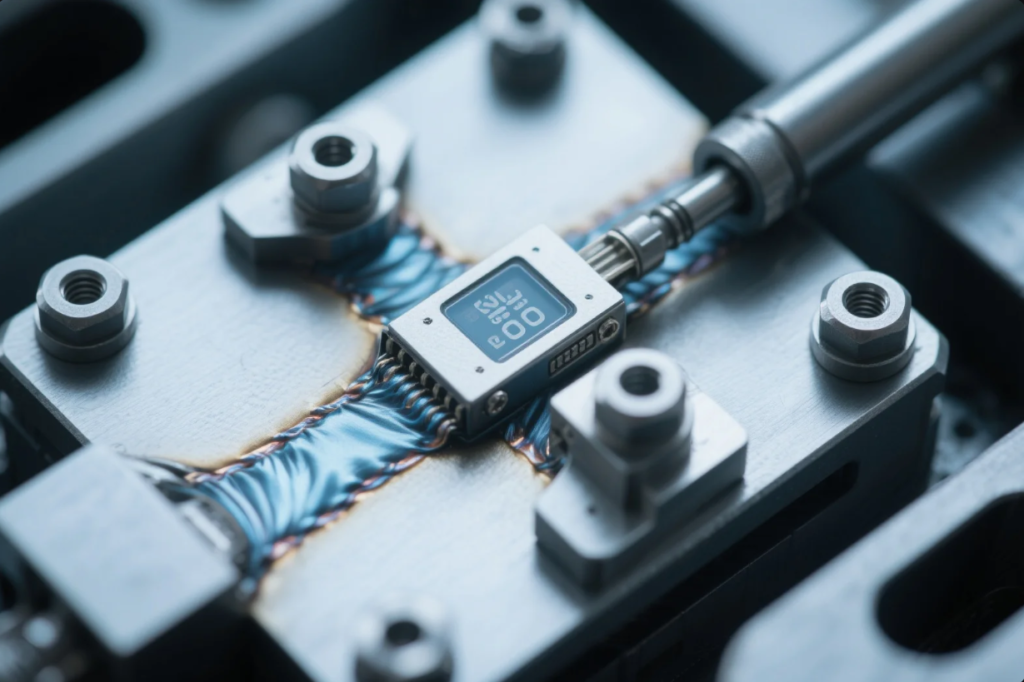

Accuracy Gains with Robotic Systems

When precision matters—for CNC frames, sensor brackets, or medical devices—robots deliver ±0.05 mm repeatability, unmatched by manual methods.

True precision leads to better assembly fit, fewer rejects, and higher customer satisfaction.

Key accuracy advantages include:

- Consistent bead width

- Stable heat input

- Auto-aligned program execution

Compliance advantages: ISO 3834, AS9100, and audit-ready traceability.

External references:

Industry Use Cases: Automotive, Aerospace, Electronics

Automotive

Robots weld thousands of identical brackets, mounts, and frames daily—ensuring consistent quality, lower scrap, and audit data.

Aerospace

Structural components and frame assemblies require precision, repeatability, and full traceability. Robots provide both.

Electronics

Thin-gauge frames and housings benefit from robotic TIG: precise, low-heat welds with clean aesthetics and high accuracy.

Frequently Asked Questions

Which welding method suits small volume?

Manual welding is ideal for short runs and custom brackets.

When should I invest in a welding robot?

If you plan to produce over 10K similar parts/year, it pays back quickly.

What tolerances can robotic systems meet?

±0.05 mm repeatability is common—suitable for aerospace and medical.

Can Prime support documentation?

Yes. Every job gets weld logs, NDT, and QC reports for full traceability.

Do you provide hybrid cells?

Yes. We combine robotic tack welds with manual finishing for best flexibility.

How long is the typical lead time?

Projects typically take 15–30 days, depending on complexity and batch size.

Which standards do you follow?

ISO 3834, AWS D1.1, AS9100, IATF—and we comply with any customer-specific procedures.

Contact Prime for Welding Support

Looking for ISO-certified precision welding? Fast service and tight tolerance results?

We can help.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Request a free consultation, DFM review, or quote today. Our team responds within 12 hours.