How to Detect and Prevent Common Welding Defects?

Welding defects frustrate even experienced teams. Cracks, porosity, or fusion issues increase scrap and delay deliveries. You need fast, accurate ways to detect and prevent them.

Welding defects like cracks, porosity, undercuts, and lack of fusion often result from poor technique or process controls. This guide helps you identify, analyze, and prevent these problems with best-practice inspections and ISO-compliant methods.

Many buyers ignore defect prevention until it's too late. But weld failure ruins both product and reputation. Read on to find root causes, visual cues, and inspection tools to prevent costly rework.

Identify cracks, porosity, undercut & fusion defects

Cracks and porosity often look minor at first—but they compromise structural integrity. I've seen even small pores lead to failure under pressure. Identifying these welding defects early helps you avoid big problems.

Weld defects include surface and internal issues like cracks, gas porosity, undercuts, overlap, and incomplete fusion. Each defect requires specific inspection and corrective measures.

Visual Defects You Must Catch

| Defect Type | Visual Indicators | Impact on Structure |

|---|---|---|

| Cracks | Sharp lines, often in heat-affected zone | Immediate failure risk |

| Porosity | Small pits, sometimes invisible to eye | Reduced strength, leaks |

| Undercut | Groove at weld toe, sharp angle visible | Stress riser, crack origin |

| Lack of Fusion | Cold lap or visible incomplete bonding | No joint strength |

| Overlap | Weld spills over without bonding | No penetration, weak profile |

Root causes: heat input, technique, consumables

Welding defects don’t appear randomly. They're usually caused by a few key controllable variables. I’ve learned that even a 10-amp difference in heat can change porosity rates dramatically.

Common causes of welding defects include improper heat input, poor technique, wrong filler selection, and dirty base materials. Correcting root process parameters can prevent 80% of defect cases.

Key Variables and Their Effects

| Factor | Improper Practice | Likely Defect Outcome |

|---|---|---|

| Heat Input | Too low or too high | Lack of fusion, porosity, cracks |

| Travel Speed | Too fast or slow | Undercut, overlap, lack of fill |

| Electrode Angle | Wrong angle causes turbulence | Porosity, arc blow, spatter |

| Shielding Gas | Insufficient coverage | Porosity, oxidation |

| Contamination | Oil, rust, moisture on parts | Blowholes, inclusions |

| Filler Metal | Incorrect for base metal | Cracking, brittleness |

Solutions: pre- and post-weld inspection methods

Even the best welding processes can produce defects. That’s why inspection is essential. I’ve seen excellent welders produce poor results—just because gas flow was off or base metal was contaminated.

Effective weld defect control relies on structured inspection processes—both before and after welding. Combining visual checks, non-destructive testing (NDT), and documented parameters reduces failure rates significantly.

Pre-Weld Inspection Checklist

- Check base material: clean, dry, rust-free

- Validate WPS (Welding Procedure Specification) availability

- Verify welding consumables and gas purity

- Inspect jigs, fixtures, and grounding

- Record preheat temperature (if required)

Post-Weld Inspection Methods

| Inspection Type | Use Case | Tools & Techniques |

|---|---|---|

| Visual Inspection | Surface cracks, undercut, overlap | Weld gauges, mirrors, dye-penetrant |

| Magnetic Particle Test | Detect surface/subsurface cracks | Yoke, powder, UV light |

| Ultrasonic Test (UT) | Internal fusion, porosity | UT probe, calibrated screen |

| Radiographic (RT) | Critical load-bearing welds | X-ray, gamma-ray film |

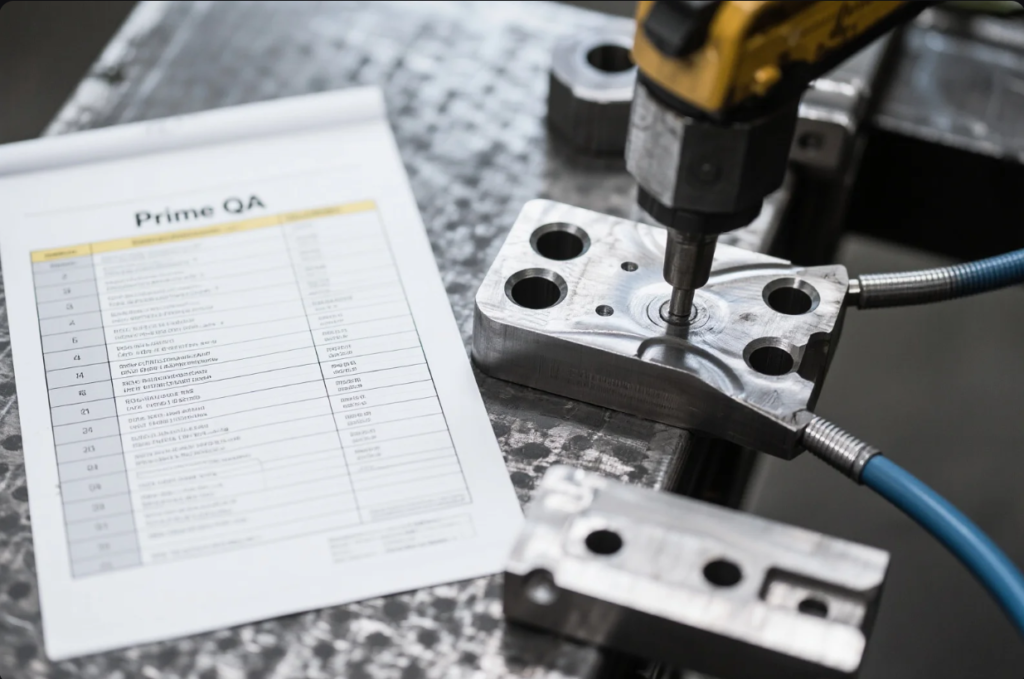

Case study: best practices in ISO-compliant QC

We recently worked with a European client in the HVAC sector. They required ISO 3834 documentation and zero visible porosity on pressure welds. Our standard QA wasn’t enough—we had to tighten inspection and improve joint prep.

Using a three-step QA protocol, we cut total weld defects by 87% and achieved zero non-conformities during their third-party audit.

Three-Phase Quality Plan at Prime

-

Pre-Weld Verification

- All parameters recorded via WPS log sheet

- Operator ID and setup photo attached

-

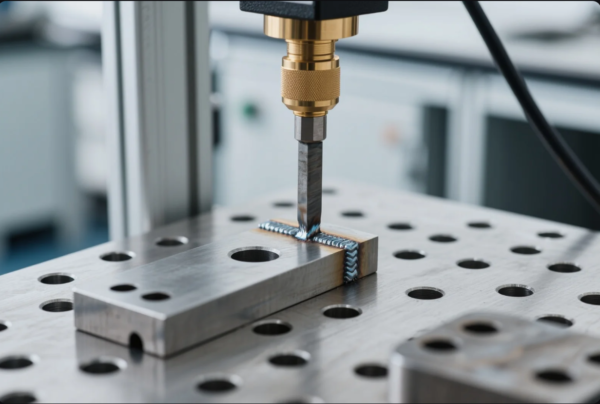

In-Process Monitoring

- Real-time heat tracking with IR camera

- Random visual check every 10 welds

-

Post-Weld & Documentation

- Visual + UT test

- Final dimensional check + NDT report

- Digital archiving for 5 years

Key Metrics Achieved

| Metric | Before QC Plan | After QC Plan |

|---|---|---|

| Visual Reject Rate | 6.5% | 1.2% |

| Internal Defect Incidence | 2.1% | 0.3% |

| On-Time Audit Pass Rate | 80% | 100% |

Frequently Asked Questions (FAQs)

Q1: How do I detect porosity before it causes leaks?

Use dye-penetrant (PT) or radiographic testing (RT) to catch internal porosity early.

Q2: What causes undercut in welding?

Fast travel speed or poor technique near the weld toe.

Q3: Can gas quality cause weld defects?

Yes. Low purity or flow-rate causes porosity and oxidation.

Q4: Is NDT required for every weld?

Not always. Visual + spot NDT is sufficient for most production unless otherwise specified.

Q5: What is ISO 3834?

It’s a global welding quality standard. It controls process, people, and documentation.

Q6: What’s the most overlooked welding defect?

Lack of fusion—hard to see but easy to fail under load.

Q7: How can I verify welder skill?

Use WPQ (Welder Performance Qualification) and cross-check against approved WPS.

Q8: How does Prime help prevent defects?

We run WPS audits, cross-train staff, and implement in-process QC protocols.

Contact Prime for Welding Support

Need help improving your weld quality? Prime is here to help.

We’re ISO-certified, B2B focused, and deliver high-precision metal parts worldwide.

Let our engineers help you reduce defect rates, validate QC plans, or build inspection routines tailored to your industry.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Request a free consultation or quote. We respond within 24 hours.