Welding Inspection & Quality Assurance Explained

Manufacturers often miss welding issues until it's too late. Quality lapses cause costly delays. You need thorough QA to build trust and reduce risk.

Weld inspection should cover every stage—from pre-weld checks to in-process monitoring and final evaluation. Applying MPI, PT, radiography, and digital vision systems ensures defect-free outcomes. Understanding AWS, ISO, and ASME standards helps guarantee compliance.

Keep reading to discover step-by-step workflows, NDT guidance, tech benefits, and standard implementations to strengthen your welding processes.

Table of Contents

- Pre-, During-, and Post-Weld Inspection Steps

- Non-Destructive Testing: MPI, PT, Radiography

- Benefits of Digital Weld Cameras & Machine Vision

- Key Standards: AWS, ISO, ASME Welding Requirements

- FAQs

- Contact Prime for Inspection & QA Services

Pre-, During-, and Post-Weld Inspection Steps

A robust QA journey follows three phases: before welding, during welding, and after welding. Skipping one increases risk of missing critical issues.

1. Pre-Weld Checks

Pre-weld inspection sets the foundation for quality welds.

- Confirm correct WPS/WPQ documents are on hand

- Inspect base metal cleanliness, dryness, and fit-up

- Check preheat or interpass temperature requirements

- Ensure correct consumables and gas cylinder traceability

- Validate fixtures, grounding, and shielding gas flow

A mistake at this stage can lead to defects like porosity or cracks.

Sources: Lincoln Electric pre-weld checklist, TWI pre-weld QA guide

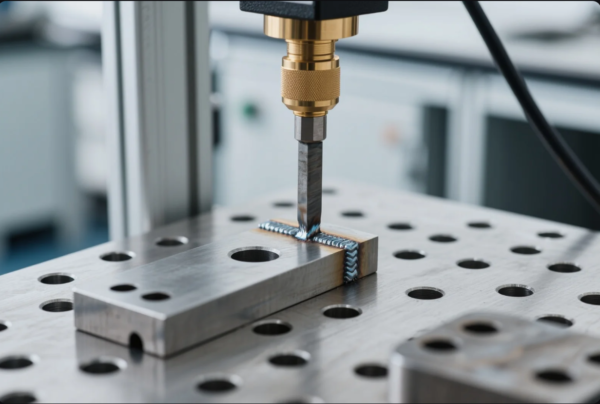

2. In-Process Monitoring

Real-time inspection improves control and prevents defects from forming.

- Log welding parameters (amperage, voltage, travel speed)

- Watch weld puddle and bead formation

- Use digital weld camera to monitor seam integrity

- Perform random visual inspections every 10–15 welds

- Track heat input using IR sensors or plate thermocouples

Real-time alerts (e.g., gas flow drop or arc deviation) trigger immediate corrective action.

Sources: Miller automatic weld log overview, ABB machine-vision QC systems

3. Post-Weld Evaluation

Post-weld inspection confirms structural integrity and compliance.

- Conduct visual inspection using weld gauges

- Use NDT: MPI for steel, PT for non-ferrous, RT/UT for critical parts

- Measure weld size, penetration depth, and heat-affected zone width

- Check part dimensions and verify alignment to drawing specifications

Document every check in QA report or digital log. This supports traceability and audit compliance.

Sources: ASME Radiography Requirements, AWS Visual Inspection Criteria

Non-Destructive Testing: MPI, PT, Radiography

Common NDT methods detect surface and internal defects without damaging the part.

Magnetic Particle Inspection (MPI)

Ideal for ferromagnetic materials to detect cracks or laps.

- Clean weld, apply magnetic field (Yoke or coil)

- Spread dry or wet magnetic powder

- View under visible or UV light to identify discontinuities

MPI finds shallow surface and near-surface flaws quickly and accurately.

Sources: ASNT MPI fundamentals, Weld MPI procedures – TWI

Dye-Penetrant Inspection (PT)

Great for surface-breaking defects on non-ferrous welds.

- Clean weld and apply penetrant

- Allow dwell time, remove excess solvent

- Apply developer and inspect under visible or UV light

- Mark and review any indications found

Cost-effective method for aluminum, stainless, and cast parts.

Sources: Magnaflux PT guide, PT acceptance standards – AWS D1.1

Radiographic Testing (RT)

X-ray or gamma-ray testing reveals internal flaws like porosity or incomplete fusion.

- Place weld between source and film or digital sensor

- Calibrate exposure for specific thickness and alloy

- Interpret density variations to detect defects

Essential for pressure vessels and structural welds.

Sources: ASME Radiographic Code, RT basics – NDT resource center

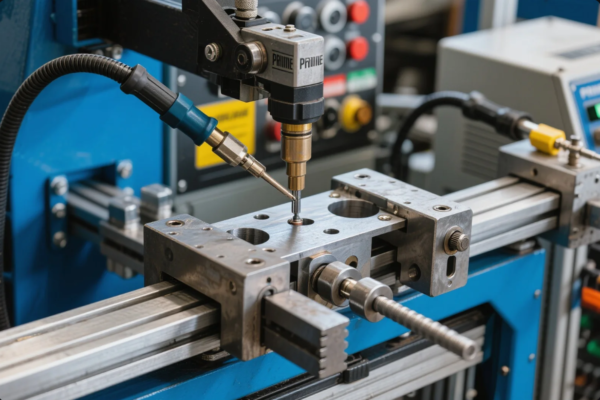

Benefits of Digital Weld Cameras & Machine Vision

High-resolution weld cameras and AI-driven systems improve defect detection accuracy and speed. They’re essential for both manual and robotic cells.

Advantages of Digital Weld Monitoring

- Real-time tracking of arc stability, weld width, penetration

- AI-assisted flaw detection (burn-through, undercut, misalignment)

- Auto-archiving of inspection footage for compliance and training

- Less reliance on operator judgment in harsh or automated environments

Many advanced systems integrate with MES (Manufacturing Execution Systems), helping QA teams identify recurring weld issues.

Digital inspection reduces human error and speeds up response to deviations.

Trusted Tech Providers

- ABB Weld Monitoring Systems

- Keyence Laser Profiling

- Cognex Smart Cameras

- Omron Vision for Welding

- MAVIS Weld AI Software

Key Standards: AWS, ISO, ASME Welding Requirements

Compliance with international welding standards is essential in industrial fabrication. These guidelines cover personnel qualifications, process controls, inspection methods, and documentation.

1. AWS (American Welding Society)

The AWS D1.1 structural welding code is widely used in steel fabrication.

Key areas include:

- Qualified WPS (Welding Procedure Specification)

- Certified welders (WPQ)

- Visual and NDT inspection criteria

- Acceptance standards for structural welds

Additional AWS standards:

- AWS D1.6 for stainless steel

- AWS B1.10M/B1.10 for visual inspection

- AWS A2.4 for weld symbols

2. ISO (International Organization for Standardization)

ISO standards are recognized globally, especially in Europe and Asia.

- ISO 3834: Quality requirements for fusion welding

- ISO 5817: Acceptance levels for weld imperfections

- ISO 17637: Visual inspection of fusion-welded joints

- ISO 9606: Welder qualification testing

Learn more:

3. ASME (American Society of Mechanical Engineers)

ASME codes are crucial in pressure vessel, boiler, and pipeline fabrication.

Notable standards:

- ASME Section IX: Welding procedure and performance qualifications

- ASME B31.1/B31.3: Power and process piping inspection

- ASME BPVC VIII: Rules for pressure vessels

More at:

Frequently Asked Questions (FAQs)

Q1: What’s the difference between MPI and PT?

MPI detects subsurface flaws in magnetic metals. PT only shows surface cracks, works on all metals.

Q2: How often should welding inspections occur?

At minimum: pre-weld setup check, in-process parameter logging, and post-weld visual/NDT as required.

Q3: Is ISO 3834 certification necessary?

Not always. But it's essential for EU clients or when bidding for regulated industry contracts.

Q4: What’s the best inspection method for stainless steel tanks?

Dye-Penetrant (PT) combined with radiographic testing (RT) if pressure-rated.

Q5: How do digital weld cameras improve QA?

They provide live feedback, record video, and detect anomalies in real time. Also support training.

Q6: What welding codes are used in aerospace?

AWS D17.1, AS9100 for quality systems, and NADCAP for special process audits.

Q7: Can Prime help with third-party inspection prep?

Yes, we prepare documentation, perform internal audits, and run pre-audit inspection reviews.

Q8: Do I need different standards for aluminum welds?

Yes. Use AWS D1.2 for aluminum and ensure proper cleaning to prevent porosity.

Contact Prime for Inspection & QA Services

Looking to reduce defect rates or prepare for audits?

Prime supports global manufacturers with:

- ISO-certified QA workflows

- In-house NDT capability (UT, PT, MPI)

- Digital weld traceability systems

- Expert weld engineering and documentation support

📧 Email us: [email protected]

🌐 Visit our site: https://primecustomparts.com

We’ll reply within 24 hours. Get a free quote or inspection audit consultation today.