The Importance of Weld Purging for Alloy Parts

Weld oxidation ruins critical alloy parts. Discoloration, weak joints, or corrosion can follow if purging is neglected. You need controlled purging to ensure joint integrity.

Weld purging—clearing oxygen from inside joints—is essential for alloys like stainless and titanium. Choosing the right gas (argon vs helium), following setup best practices, and monitoring purge quality prevents oxidation and ensures durable weld quality.

Read on to explore how purge welding works, gas choices, setup methods, and industry applications.

Table of Contents

- What Is Weld Purging and Why It Matters

- Argon vs Helium: Choosing the Right Gas

- Setup Best Practices to Reduce Oxidation

- Industries Relying on Purge Welding: Stainless, Titanium

- FAQs

- Contact Prime for Alloy Weld Purging Services

What Is Weld Purging and Why It Matters

Weld purging means flushing inert gas inside the root side of a weld joint before and during welding. It removes oxygen that causes oxidation, discoloration, and carbide precipitation.

Without proper purging, alloys degrade: stainless loses corrosion resistance, titanium becomes brittle, and weld scale forms quickly. Purge welding prepares a clean, inert atmosphere to preserve alloy properties.

Core Reasons to Use Purge Welding

- Prevents oxidation and discoloration

- Maintains corrosion resistance in stainless

- Avoids alpha case formation in titanium

- Ensures clean internal pipe surfaces

Sources:

- ASTM on stainless welding discoloration

- Oxygen control in titanium welding – TWI

- Weld purging methods – Lincoln Electric

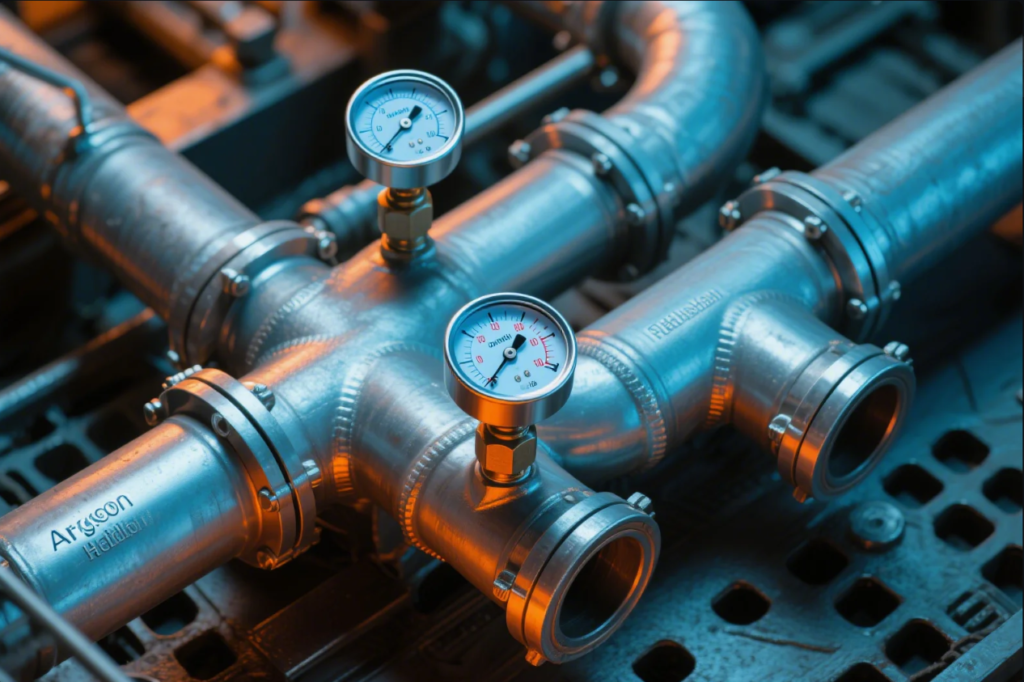

Argon vs Helium: Choosing the Right Gas

Selecting the right gas for purge welding influences cost, weld quality, and machine setup. Here's how argon and helium compare:

Argon is the most common purge gas. It’s heavy, cost-effective, and maintains a stable weld environment—but has slower flow and lower thermal conductivity.

Helium is lighter, offers deeper heat penetration, and improves weld flow—but is more expensive and can require higher flow rates.

Gas Comparison Table

| Feature | Argon | Helium |

|---|---|---|

| Cost | Lower | Higher |

| Thermal Conductivity | Moderate | High |

| Flow Control | Simple, easy | Higher flow and turbulence |

| Weld Profile | Stable bead shape | Deeper penetration, wider |

| Application | Most stainless applications | Thick-gauge or root passes |

Pro tip:

For stainless up to 6 mm, pure argon is sufficient. For titanium or thicker wall sections, helium blends (25–50%) improve penetration and fluidity.

Sources:

Setup Best Practices to Reduce Oxidation

Even with high-purity gas, improper setup can ruin purge results. Leak paths, improper flow, or poor timing can lead to oxidation.

Follow these steps to ensure successful purging before arc start:

Purging Setup Tips

- Seal ends tightly using purge dams, foam plugs, or bladders

- Use flow meters to regulate purge rate (typically 10–20 SCFH)

- Purge with sufficient time (3–5 minutes minimum for small pipes)

- Use oxygen sensors to confirm below 50 ppm before welding

- Back-purge throughout welding, especially for long seams

Even trace oxygen ruins titanium and duplex welds. Using real-time oxygen sensors like Purge Monitor™ prevents guesswork.

Don’t Ignore These Mistakes

- Skipping purge timing (too short = discolored weld)

- Overheating seals causing air leaks

- Using low-quality gas or dirty hoses

- Welding before oxygen reaches safe threshold

Resources:

- Purge dam selection – AWS Welding Journal

- Pipe welding purge setups – Orbitalum

- Back-purging guide – ESAB

Industries Relying on Purge Welding: Stainless, Titanium

Certain industries can’t tolerate oxidation—even microscopically. For them, purge welding isn’t optional. It’s essential.

Sectors Where Weld Purging is Critical

- Pharmaceutical & Food Processing: interior pipe must remain oxide-free

- Semiconductor & Biotech: ultrapure stainless needs clean ID welds

- Aerospace: titanium welds must avoid alpha case embrittlement

- Nuclear & Petrochemical: high-pressure duplex and Inconel pipe needs strict purge control

Purging ensures safety, hygiene, and strength in high-risk environments.

Popular Alloys Requiring Purge

| Alloy | Reason for Purge | Typical Application |

|---|---|---|

| 316L Stainless | Prevent corrosion/discoloration | Process piping, tanks |

| Duplex 2205 | Avoid phase imbalance | Offshore oil piping |

| CP Titanium | Prevent oxygen embrittlement | Jet engine tubing |

| Inconel 625 | Maintain high-temp performance | Chemical reactors |

Explore more:

- ASME BPE Process Piping Guide

- Titanium Weld Standards – TWI

- Biotech sanitary welding handbook – Alfa Laval

Frequently Asked Questions (FAQs)

Q1: How low should oxygen levels be before starting the weld?

Below 50 ppm for stainless; under 10 ppm for titanium or duplex.

Q2: Can nitrogen be used as a purge gas?

Only for mild steel. Nitrogen reacts with stainless and titanium under heat.

Q3: What tools help monitor purge effectiveness?

Oxygen analyzers, purge monitors, and pressure relief valves are key.

Q4: Is helium always better than argon?

Not always. Helium improves penetration but is costly and harder to control.

Q5: How can I purge long pipe runs?

Use inflatable bladder systems or trailing purge chambers to maintain flow.

Q6: Should I keep purging after welding?

Yes. Maintain gas flow during cooldown to avoid post-weld oxidation.

Q7: How do I avoid purge gas turbulence?

Use smooth flow paths, diffusers, and regulate with a proper flowmeter.

Q8: Do all stainless alloys need purging?

No. Ferritic grades may tolerate it, but austenitic and duplex must be purged.

Contact Prime for Alloy Weld Purging Services

Purge welding can make or break your alloy parts. Don’t risk it with substandard processes.

At Prime, we specialize in:

- Controlled argon and helium purging for alloy welds

- Real-time oxygen analysis and purge monitoring

- Expert stainless and titanium welders

- Weld certification to ISO and ASME standards

📧 Email us: [email protected]

🌐 Website: https://primecustomparts.com

We respond within 24 hours. Ask us how we can improve your weld quality and process efficiency.