CNC vs Injection Molding: Best Methods for Plastic Parts

Choosing between CNC machining and injection molding is a key decision in plastic part production. This in-depth guide compares both methods based on cost, lead time, accuracy, and application to help engineers, procurement professionals, and OEMs choose the right strategy for their plastic projects.

📚 Table of Contents

- Introduction

- CNC Machining for Prototypes

- Injection Molding for Mass Production

- Cost Comparison: CNC vs Injection Molding

- Transition Strategy: From Prototypes to Production

- Conclusion

- FAQs

- Contact Us

- External Resources

Introduction

Plastic components are used across industries such as automotive, electronics, medical, packaging, and consumer goods. Whether you’re creating a custom enclosure for a sensor, a disposable surgical instrument, or a functional prototype for product development, choosing the right manufacturing method is critical.

CNC machining and injection molding are two of the most common manufacturing options for plastic components. Each has unique advantages depending on:

- Part geometry

- Tolerance and surface finish requirements

- Material compatibility

- Order quantity

- Budget and development timeline

Let’s explore how both processes work, where they shine, and how to use them strategically — sometimes even together.

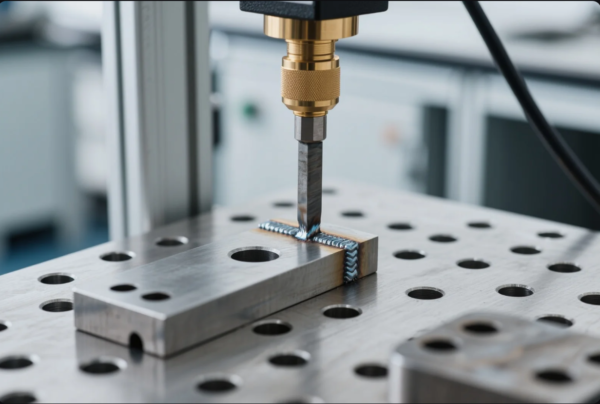

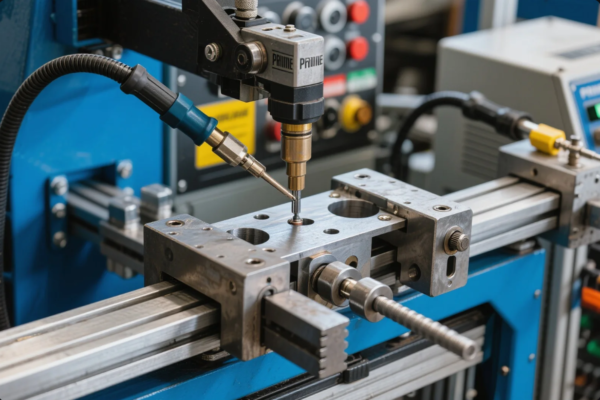

CNC Machining for Prototypes

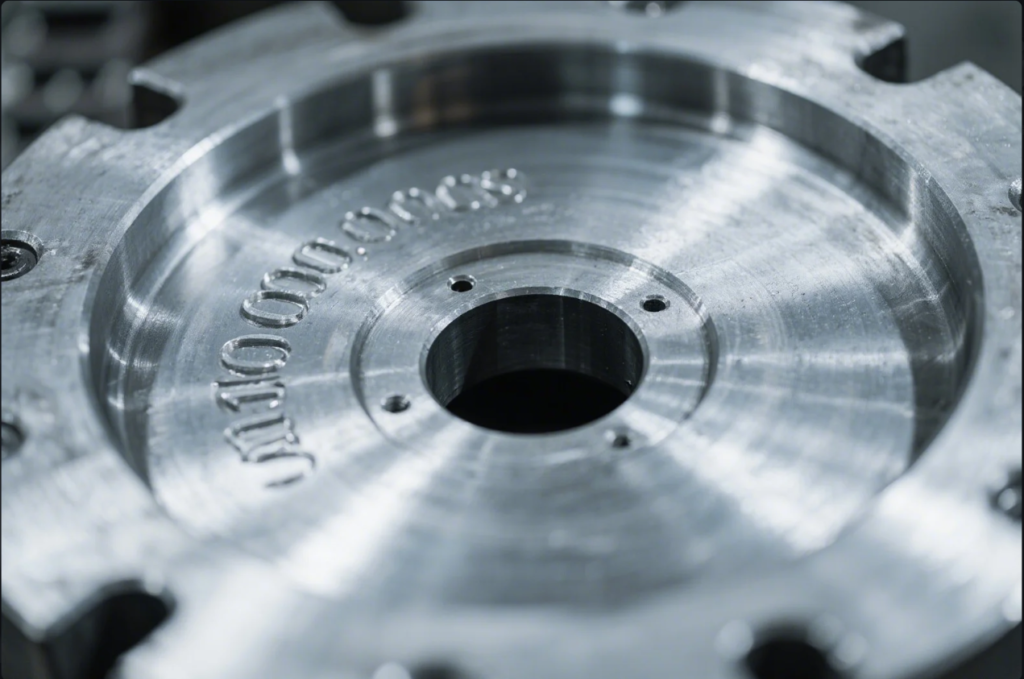

CNC machining is a subtractive manufacturing method that removes material from a solid plastic block using computer-controlled tools.

🛠️ Key Benefits of CNC Machining

- Exceptional precision: ±0.01 mm or better

- Material compatibility: Works with high-performance plastics like PEEK, PTFE, Delrin (POM), PC, ABS, PA

- No mold tooling required: Faster iteration

- Rapid delivery: 2–5 business days for prototypes

🧪 Ideal Applications

- Engineering validation parts

- Aerospace functional testing (nasa.gov)

- One-off industrial replacements

- Small-run medical parts (fda.gov)

- Low-quantity fixtures or tooling for assembly lines

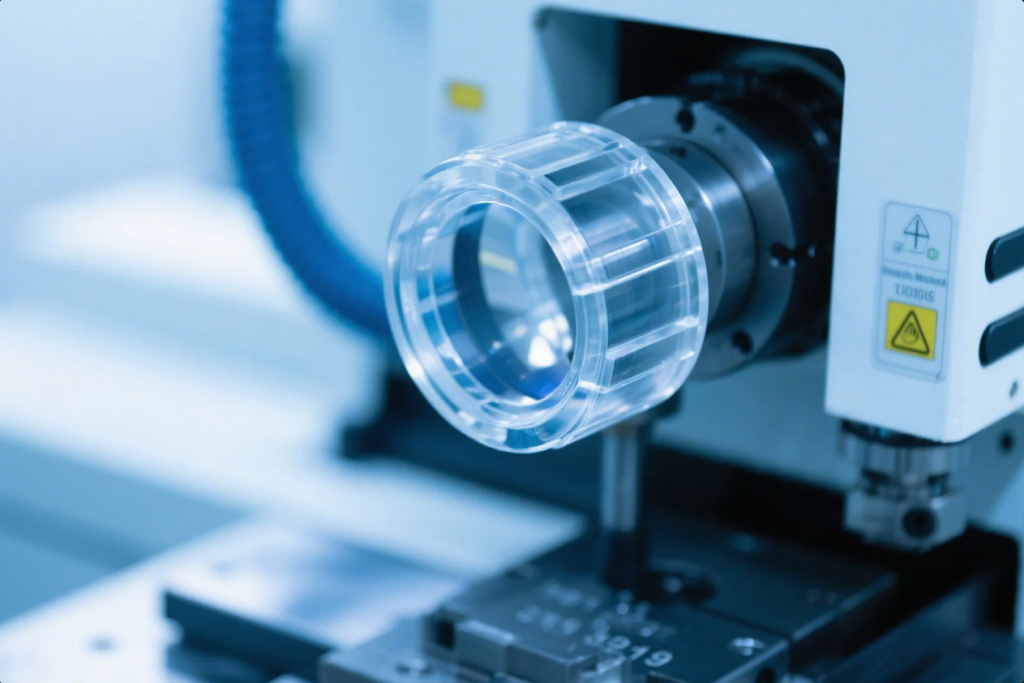

✅ CNC Surface Finish

- As-machined

- Polished

- Bead blasted

- Anodized (for aluminum)

📘 Learn about CNC finishing options

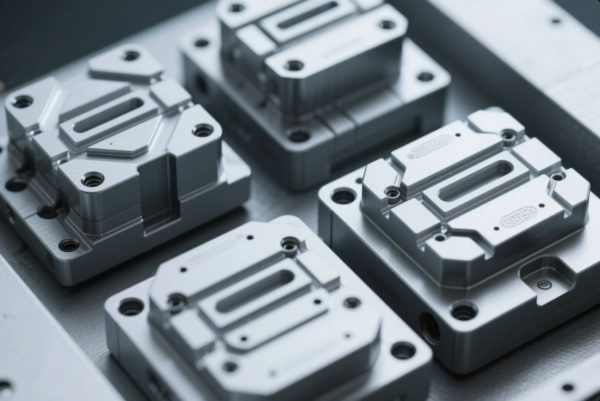

Injection Molding for Mass Production

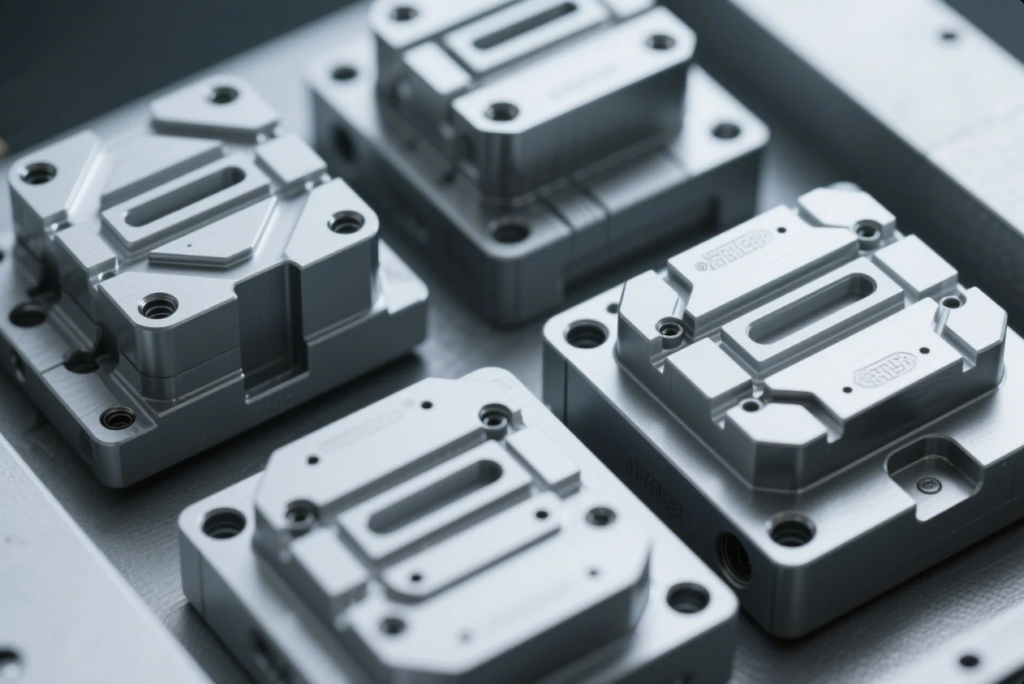

Injection molding involves injecting molten plastic into a metal mold cavity at high pressure. It’s ideal for high-volume, repeatable plastic part production.

🚀 Advantages of Injection Molding

- Scalability: Suitable for producing 1,000 to millions of parts

- Low cost per part: After initial mold investment

- Excellent surface finishes: Texture, gloss, matte

- Consistent tolerances: ±0.05 mm across batches

- Material range: PP, ABS, PC, PS, TPE, PA, filled resins

🔁 Typical Applications

- Automotive interior clips and covers (bosch.com)

- Electrical enclosures (schneider-electric.com)

- Consumer packaging (tetrapak.com)

- Tool handles and grips (stanleytools.com)

📘 Intro to Injection Molding by Hubs

Cost Comparison: CNC vs Injection Molding

| Feature | CNC Machining | Injection Molding |

|---|---|---|

| Tooling Cost | \$0–\$500 | \$3,000–\$25,000+ |

| Per-Unit Cost (Low Volume) | \$20–\$150 | \$10–\$100 (expensive) |

| Per-Unit Cost (High Volume) | \$15–\$40 | \$0.5–\$5 |

| Lead Time | 2–5 days | 3–6 weeks |

| Design Iteration Speed | Instant | Slow (requires new mold) |

📎 Compare online with tools:

Transition Strategy: From Prototypes to Production

A proven method for many product teams is to use CNC machining for R\&D and switch to molding once the design is finalized.

🔄 Typical Development Path

- CAD Design & Feasibility Review

- Rapid CNC Prototyping for Testing

- Design for Manufacturability (DFM)

- Injection Mold Fabrication (3–5 weeks)

- Pilot Run Validation

- Full Production Launch

👨🔧 Tips for Smooth Transition

- Use consistent materials in both stages (e.g., ABS, Nylon)

- Add draft angles and avoid undercuts early

- Follow ISO 20457:2023 guidelines for plastic design

Conclusion

Both CNC machining and injection molding offer powerful advantages:

- CNC is perfect for fast iterations, low volume, and precision parts

- Injection molding dominates in large-scale, consistent production

Using them together — with CNC for prototypes and molding for mass production — is a best-practice approach.

FAQs

Q1: What is the minimum order quantity for injection molding?

A: Technically, even one part is possible — but cost per part is extremely high. It’s best for 500+ units.

Q2: Can I use the same CAD file for both methods?

A: Yes, but you’ll likely need to revise it for moldability (e.g., adding draft angles).

Q3: Can CNC parts be used for real products?

A: Absolutely. Especially in medical, defense, or aerospace where the production volume is low and precision is key.

Q4: How can I reduce injection mold cost?

A: Use family molds, reduce part complexity, and opt for aluminum tooling for shorter runs.

Q5: What’s the typical lifespan of a mold?

A:

- Aluminum: 10,000–25,000 shots

- Steel (H13, P20): 100,000–1 million shots

Contact Us

Looking for a trusted partner for plastic part production — from prototype to high-volume manufacturing?

🌐 Website: https://primecustomparts.com

📧 Email: [email protected]

We offer full-service support including DFM reviews, CAD optimization, CNC, injection tooling, and ISO-compliant quality inspection.