Injection Molding Tolerances & Surface Finishes Demystified

📚 Table of Contents

- Introduction

- Understanding Injection Molding Tolerances

- Standard vs Precision Molding: ±0.05 mm vs ±0.01 mm

- SPI Surface Finish Standards Explained

- Mold Texturing and Cosmetic Surface Impact

- QA Checklist for Injection Molded Parts

- Conclusion

- FAQs

- Contact Us

Introduction

Injection molding is the preferred process for high-volume plastic part production — but achieving high-quality outcomes requires tight dimensional control and attention to surface finish.

This article demystifies the key tolerancing standards and surface classifications used in the industry. Whether you’re designing parts for automotive, medical, or consumer products, these guidelines will help ensure you receive consistent, defect-free molded components.

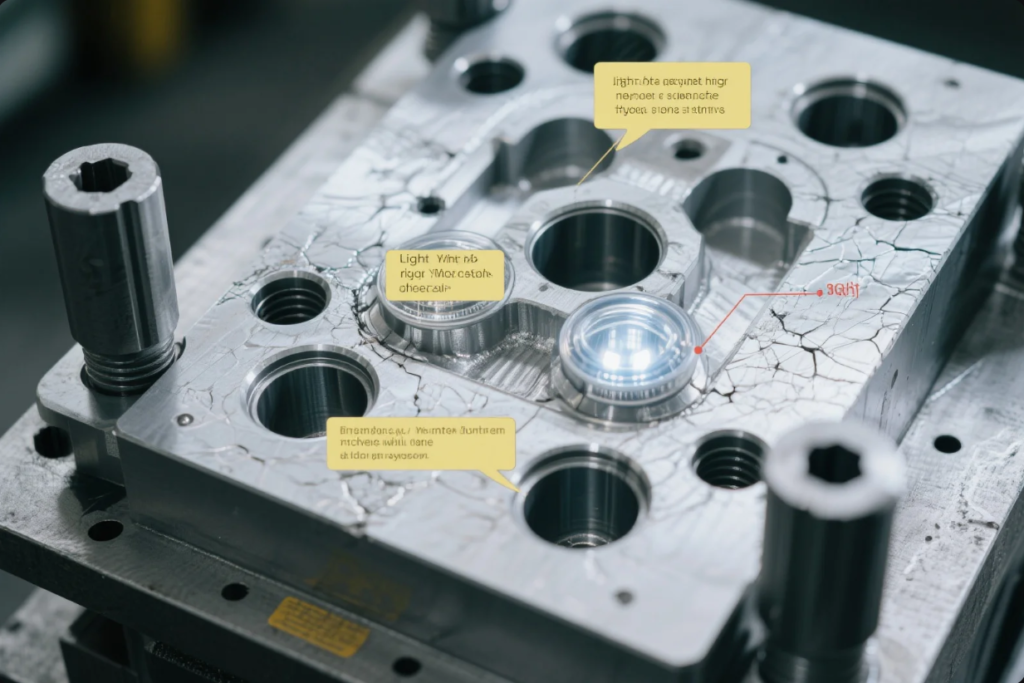

Understanding Injection Molding Tolerances

Tolerances define how much variation is acceptable between a part’s intended dimension and its actual measurement after molding.

Why Tolerances Matter:

- Ensure interchangeability and proper assembly

- Prevent defects like misalignment or warping

- Meet industry specs such as ISO 20457, DIN 16901, or SPI standards

📎 Tolerances Guide by Protolabs

📎 Xometry Tolerance Chart

Standard vs Precision Molding: ±0.05 mm vs ±0.01 mm

🟡 Standard Tolerances (±0.05–0.1 mm)

- Achievable with most multi-cavity P20 or aluminum molds

- Good for consumer products, brackets, enclosures

- Example: ABS phone housing

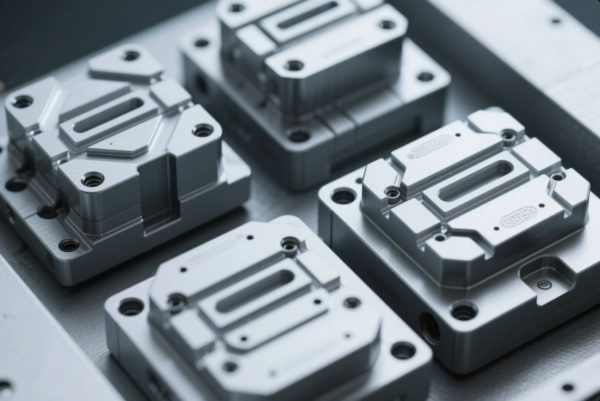

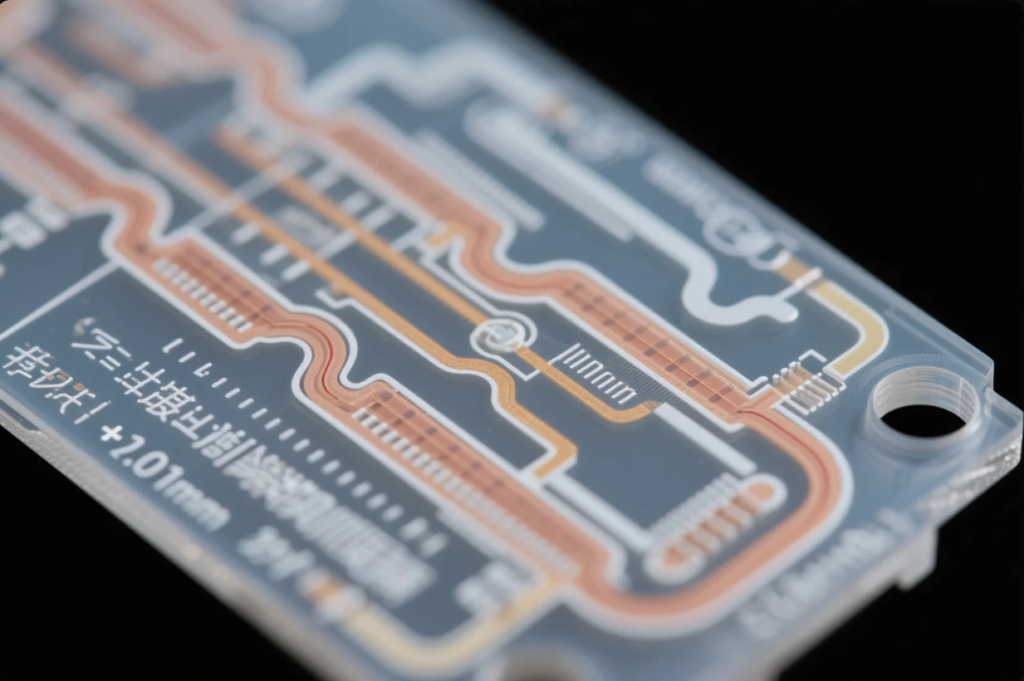

🟢 Precision Molding (±0.01–0.02 mm)

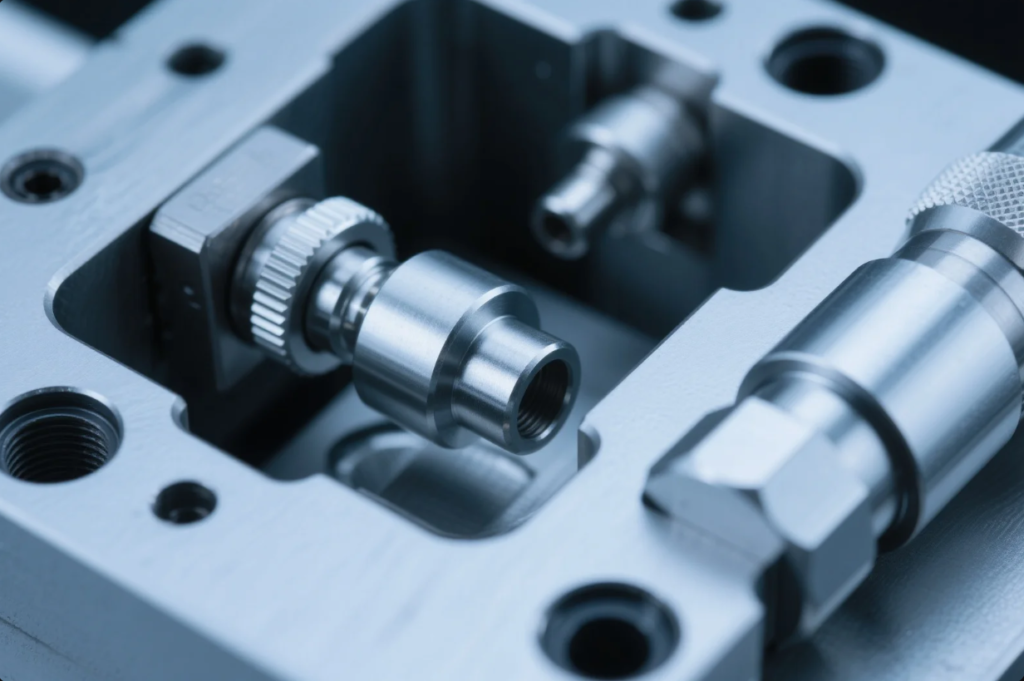

- Requires hardened steel tooling (H13, S136)

- CNC-machined inserts and EDM for accuracy

- Common in medical, optical, and aerospace parts

📎 SPI Dimensional Tolerance Standard

📎 Stack Plastics: Precision Molding for Medical

SPI Surface Finish Standards Explained

The Society of the Plastics Industry (SPI) categorizes mold surfaces from A1 (mirror polish) to D3 (rough blasted).

| Grade | Process | Typical Use |

|---|---|---|

| A1 | Diamond buff | Optical lenses, medical housings |

| B2 | Semi-gloss mold polish | Consumer appliances |

| C1 | Sandpaper matte | Structural automotive parts |

| D3 | Bead-blasted textured | Housings, grip zones |

📎 SPI Finish Chart Reference

📎 SPI Standards PDF – Mold-Tech

Mold Texturing and Cosmetic Surface Impact

Texturing improves both function and appearance.

Types of Mold Textures:

- Chemical etching: Adds precise patterns (e.g., leather, grain)

- Laser engraving: Complex textures with micro-control

- Sandblasting/bead blasting: Creates soft matte finishes

Applications:

📎 Mold-Tech Surface Library

📎 Covestro Textured PC Case Study

QA Checklist for Injection Molded Parts

Quality assurance in injection molding involves inspecting parts for:

🔍 Dimensional Defects

- Warping

- Shrinkage variation

- Out-of-tolerance features

📎 Dimensional Inspection Guide – ZEISS

🔍 Cosmetic Defects

- Flow lines

- Sink marks

- Jetting, weld lines

📎 Surface Defects Illustrated – DME

🔍 Mold & Flash Defects

- Short shots

- Flash over parting line

- Burn marks from trapped gases

📎 Scientific Molding QA Control – RJG

📎 Design for Moldability – Hubs

Conclusion

Achieving precise tolerances and desirable surface finishes in injection molding requires:

- Understanding design limitations

- Partnering with a tooling expert

- Clear documentation of QA checkpoints

- Choosing appropriate SPI textures and tolerances by part function

From ±0.01 mm tight-tolerance micro parts to large cosmetic enclosures, successful molding depends on collaboration across design, tooling, and QA teams.

FAQs

Q1: What is the tightest tolerance injection molding can achieve?

A: Precision tooling can reach ±0.005 mm in very controlled environments using PEEK or LCP materials.

Q2: What SPI finish is best for gloss?

A: A1 (diamond polish) is the best for high-gloss and optical surfaces.

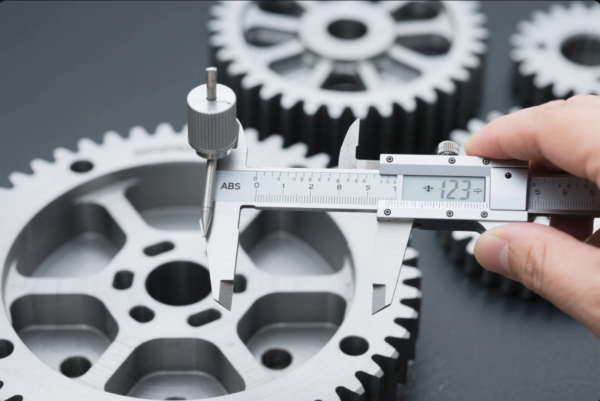

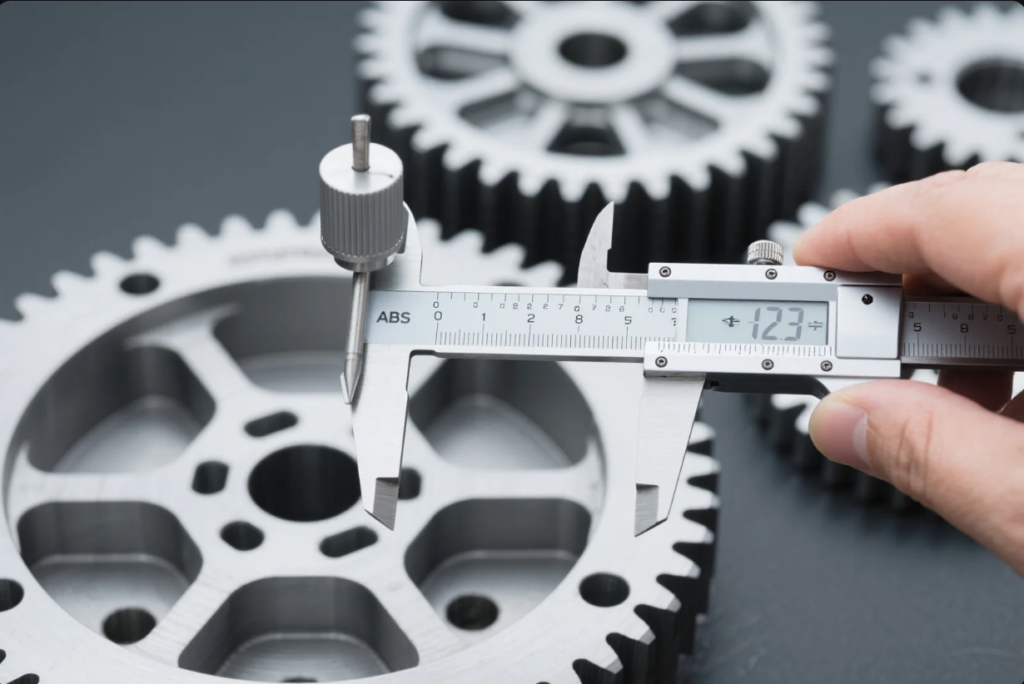

Q3: How do you measure injection molded parts?

A: Common tools include calipers, CMMs (Coordinate Measuring Machines), and optical comparators.

Q4: Can surface textures be added after molding?

A: Rarely — surface textures must be machined or etched into the mold. Post-processing is costly and inconsistent.

Q5: What finish hides sink marks and flow lines best?

A: Matte textures like SPI C1 or bead-blasted D2 surfaces.

Contact Us

Need ultra-precise plastic parts or want to improve your molded product’s surface finish?

🌐 Website: https://primecustomparts.com

📧 Email: [email protected]

Our engineering team provides full support for DFM, mold texture guidance, and tolerancing documentation.