OEM Plastic Part Production: From DFM to Mass Production

📚 Table of Contents

- Introduction

- Early-Stage DFM Tips: Wall Thickness, Draft Angles, Radii

- Prototyping Pipeline: 3D Printing, CNC, and Soft Tooling

- T1 Sampling and Inspection Protocols

- Scalable Production: Global Logistics and Packaging

- Conclusion

- FAQs

- Contact Us

Introduction

Bringing an OEM plastic part to life involves far more than injection molding. It begins with design for manufacturability (DFM), flows through prototyping, tooling validation, and concludes with packaged, globally shipped final parts.

This guide walks you through every stage of production — from early design decisions to logistics — ensuring you avoid costly delays and defects.

Early-Stage DFM Tips: Wall Thickness, Draft Angles, Radii

Designing a plastic part starts with DFM, the foundation for both cost efficiency and moldability.

✅ Wall Thickness

- Ideal: 1.0–3.0 mm for most thermoplastics

- Too thick: Causes sink marks and warping

- Too thin: May result in short shots

📎 Recommended wall thickness by material – Protolabs

📐 Draft Angles

- General rule: 1–2° per side

- SPI A1 surfaces may require up to 3°

- Ensures easy part ejection and longer mold life

📎 Draft angle calculator – Hubs

🌀 Radii

- Fillets reduce stress concentration

- Avoid sharp corners in core/cavity transitions

- Use inside radius ≥ 0.5x wall thickness

📎 Fillet & Radius Design Tips – Xometry

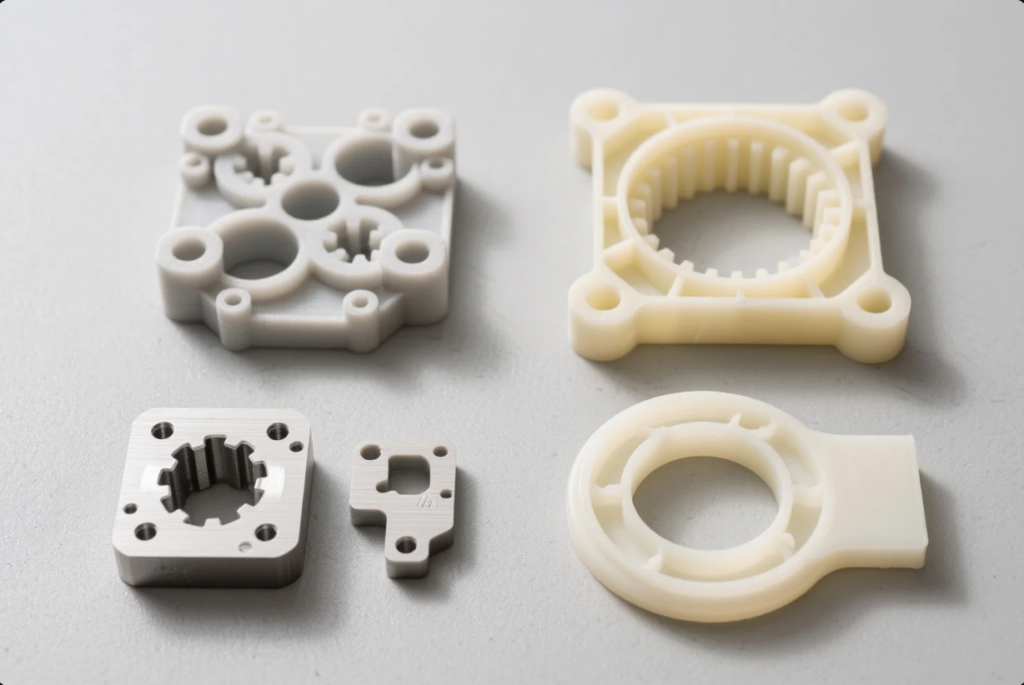

Prototyping Pipeline: 3D Printing, CNC, and Soft Tooling

Prototyping verifies fit, function, and manufacturability before investing in full tooling.

1. 3D Printing (Additive)

- Fast and low-cost

- Best for early visual or ergonomic validation

- Common processes: FDM, SLA, SLS

📎 3D printing vs molding comparison – Stratasys

2. CNC Machining

- Excellent for high-fidelity, test-ready prototypes

- Uses final production materials (e.g., POM, PC, PEEK)

- Tolerance: ±0.01 mm possible

📎 CNC vs 3D print for prototypes – Fictiv

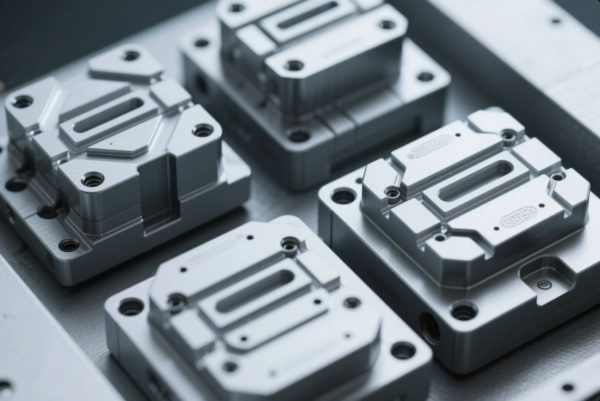

3. Soft Tooling (Bridge Molds)

- Aluminum or low-volume steel tooling

- Short lead time (7–15 days)

- Produces 100–5,000 parts

📎 Soft tooling overview – RapidDirect

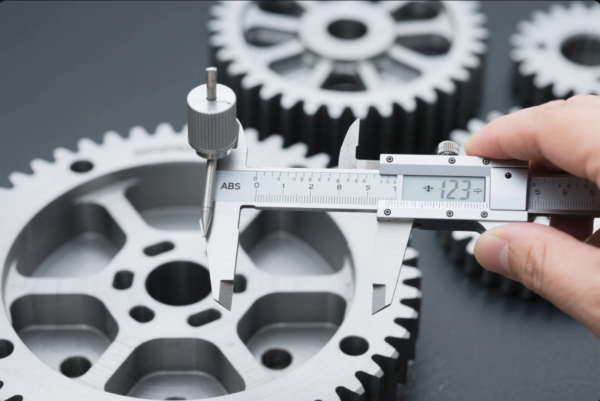

T1 Sampling and Inspection Protocols

After mold fabrication, the T1 sample is the first critical milestone in production approval.

📌 T1 Checklist

- Visual defects: flow lines, weld marks, flash

- Dimensional accuracy: caliper or CMM report

- Part weight vs theoretical CAD weight

- Material certificate & resin lot tracking

📎 T1 to T3 mold sampling stages – Star Rapid

📊 Inspection Methods

- Manual gauges

- Coordinate Measuring Machine (CMM)

- Optical vision systems (key for microfeatures)

📎 ZEISS CMM metrology solutions

Scalable Production: Global Logistics and Packaging

When production ramps, logistics becomes as critical as manufacturing.

🌍 International Logistics

- Sea freight for large batches (cheapest, slowest)

- Air freight for urgent orders or high-value parts

- Consider DDP, FOB, and EXW terms for delivery clarity

📦 Packaging Best Practices

- Custom trays or vacuum-forming to prevent part deformation

- Include silica gel if parts are moisture-sensitive

- Double boxing for fragile or high-gloss finishes

📎 Packaging for injection molded parts – Packlane

🔁 Reorder and Batch Scheduling

- Use ERP systems like NetSuite or Katana

- Forecast demand with lead time buffers

- Validate every new resin lot

📎 How to scale injection molded production – Hubs

Conclusion

OEM plastic part production is a multi-stage process:

- DFM ensures your part is moldable and optimized

- Prototyping eliminates risk before tooling investment

- T1 sampling validates performance, dimensions, and materials

- Packaging and logistics protect and deliver your parts worldwide

Success requires cross-functional alignment — from engineering to procurement to logistics.

FAQs

Q1: When should I use soft tooling instead of full steel molds?

A: Use soft tooling for bridge production (100–5,000 pcs) when testing markets or pre-launch fulfillment.

Q2: What is a good draft angle for ribs and bosses?

A: 1.5°–2.0° is preferred, but may vary by surface finish and part height.

Q3: Can I mold high-tolerance parts in soft molds?

A: Yes, but only for tolerances ≥ ±0.05 mm. For tighter tolerances, hardened steel is preferred.

Q4: What's the average lead time from CAD to mass production?

A: Typical cycle:

- DFM & prototype: 5–10 days

- Tooling: 15–30 days

- T1 to PPAP approval: 5–15 days

- Mass production: 2–6 weeks

Q5: Do I need to texture prototypes?

A: Not always. Texture is mostly applied to soft molds or final production molds. Prototype parts are usually as-machined.

Contact Us

Looking for a reliable partner for OEM plastic part development?

🌐 Website: https://primecustomparts.com

📧 Email: [email protected]

We help global clients move from CAD to container — fast, accurately, and with quality you can trust.