Plastic Material Selection for High-Performance OEM Components

📚 Table of Contents

- Introduction

- Material Selection Criteria for OEM Components

- Top High-Performance Plastics for OEM Applications

- Industry-Specific Plastic Recommendations

- Trade-offs in Cost, Strength & Processability

- Material Testing, Certifications, and Compliance

- Conclusion

- FAQs

- Contact Us

Introduction

Selecting the right plastic for OEM parts is critical to balancing performance, cost, regulatory compliance, and manufacturability. High-performance thermoplastics such as PEEK, PPS, PA66, and PC are revolutionizing industries like aerospace, medical, automotive, and electronics.

This guide helps engineers and procurement professionals evaluate and select the best plastics for demanding applications — with real-world examples and technical insights.

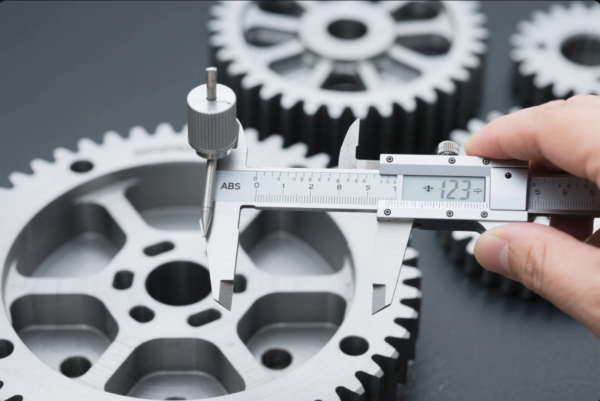

Material Selection Criteria for OEM Components

When choosing a plastic for OEM use, consider:

🧪 Mechanical Properties

- Tensile strength

- Flexural modulus

- Impact resistance (Charpy/Izod)

📎 Tensile Testing Explained – Instron

🔥 Thermal Properties

- Heat deflection temperature (HDT)

- Continuous service temperature

- Thermal expansion

📎 Thermal Properties of Plastics – Matmatch

🧼 Chemical Resistance

- Solvents, acids, hydrocarbons, sterilization agents

- Use Cole-Parmer chemical compatibility tool

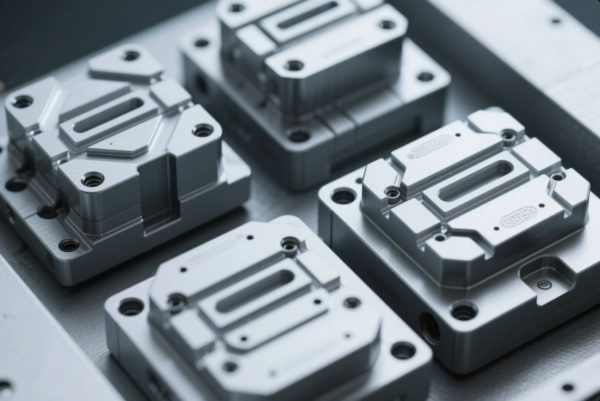

🧩 Processing Compatibility

- Injection molding vs CNC machining vs extrusion

- Recyclability and additive compatibility

📎 Design for Plastics Processing – Autodesk Moldflow

Top High-Performance Plastics for OEM Applications

🔶 PEEK – Polyetheretherketone

- Temp resistance: 250°C

- Excellent chemical resistance

- Sterilizable (autoclave, gamma, EtO)

- Aerospace, medical, and oil & gas use

📎 PEEK Overview – Victrex

📎 Medical-Grade PEEK – Evonik VESTAKEEP

🔷 PPS – Polyphenylene Sulfide

- Temp: up to 220°C

- Flame retardant without additives

- Electrically insulating

- Used in electronics and automotive connectors

📎 PPS Datasheet – Solvay Ryton

⚙️ PA66 – Nylon 66 (Glass-Filled Grades)

- High mechanical strength

- Good wear resistance

- Available as 30% GF, 50% GF grades

- Ideal for gears, brackets, bushings

📎 PA66 Glass-Filled – BASF Ultramid®

💡 PC – Polycarbonate

- High impact strength and transparency

- Temp resistance: up to 135°C

- Applications: light diffusers, medical housings

📎 Lexan™ Polycarbonate – SABIC

Industry-Specific Plastic Recommendations

🚗 Automotive

| Application | Recommended Plastic |

|---|---|

| Under-hood connectors | PPS, PA66-GF |

| Sensor housings | PBT, PC/ABS |

| Lightweight structural | Long fiber PP, PA6-GF |

🏥 Medical Devices

| Application | Recommended Plastic |

|---|---|

| Surgical tools | PEEK, PPSU |

| Housings & trays | PC, ABS, PP |

| Disposable devices | LDPE, HDPE |

✈️ Aerospace

| Component | Recommended Plastic |

|---|---|

| Electrical isolation | PEI, PPS, PTFE |

| Cabin interiors | PC, PC/ABS, PPS |

| Fuel systems | PEEK, PVDF |

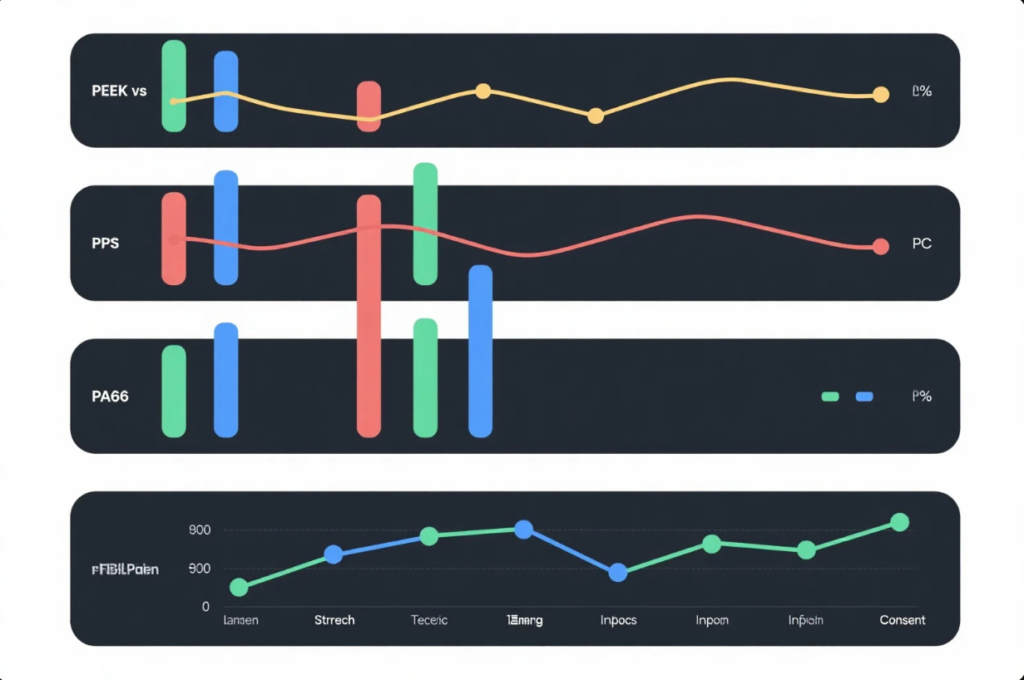

Trade-offs in Cost, Strength & Processability

| Material | Temp (°C) | Strength | Cost Index | Machinability | Moldability |

|---|---|---|---|---|---|

| PEEK | 250 | Very High | \$\$\$\$ | Excellent | Good |

| PPS | 220 | High | \$\$\$ | Moderate | Excellent |

| PA66-GF | 150 | High | \$\$ | Moderate | Excellent |

| PC | 135 | Medium | \$\$ | Excellent | Excellent |

| ABS | 85 | Medium | \$ | High | High |

📎 Omnexus Plastic Selector

📎 Plastics Comparison Tool – Matmatch

Material Testing, Certifications, and Compliance

🔬 Testing Standards

- ASTM D638 – Tensile Strength

- ISO 527 – Mechanical properties

- ISO 1133 – Melt flow index

- UL 94 – Flammability

📎 ASTM International

📎 UL 94 Standards

📜 Certifications

- FDA 21 CFR 177: Medical & food safety

- RoHS / REACH: Hazardous substance regulation

- ISO 10993: Biocompatibility

- EN 45545: Railway fire safety

📎 ISO 10993 Explained – Toxikon

📎 FDA 21 CFR Polymer List

Conclusion

Choosing the right plastic for OEM components involves:

- Understanding application demands

- Evaluating mechanical, thermal, and chemical properties

- Matching with processing method (molding, machining)

- Ensuring regulatory compliance

The smartest OEMs work with suppliers who provide material samples, property charts, compliance certificates, and technical support.

FAQs

Q1: What’s the difference between PA6 and PA66?

A: PA66 offers better strength and thermal resistance than PA6. PA6 is slightly more flexible and moisture-absorbent.

Q2: Is PEEK biocompatible?

A: Yes. Many PEEK grades comply with ISO 10993 and USP Class VI for medical implants.

Q3: Can I CNC-machine PA66 and PPS?

A: Yes. PA66 and PPS both machine well with sharp tools and proper chip clearance.

Q4: Are flame-retardant plastics halogen-free?

A: Many modern FR plastics are halogen-free and meet UL 94 V-0 and EN 45545 standards.

Q5: How do I know which plastic meets RoHS?

A: Look for RoHS-certified materials and request material data sheets (MSDS) and test reports.

Contact Us

Need help choosing the right plastic for your high-performance OEM components?

🌐 Website: https://primecustomparts.com

📧 Email: [email protected]

Our team supports material selection, prototyping, compliance consulting, and scalable production for global OEMs.