Deep Drawing in Metal Stamping: Die Design and Applications?

Table of Contents

- What is deep drawing and how does it differ from standard stamping?

- Critical design factors for deep drawing dies

- Common deep drawing defects and how to prevent them

- Automotive case study: Fuel filter housing

- Electronics case study: Lithium battery canisters

- 15 Deep Drawing RFQ Questions with Answers

- Deep Drawing FAQ

- Conclusion

- Contact Prime

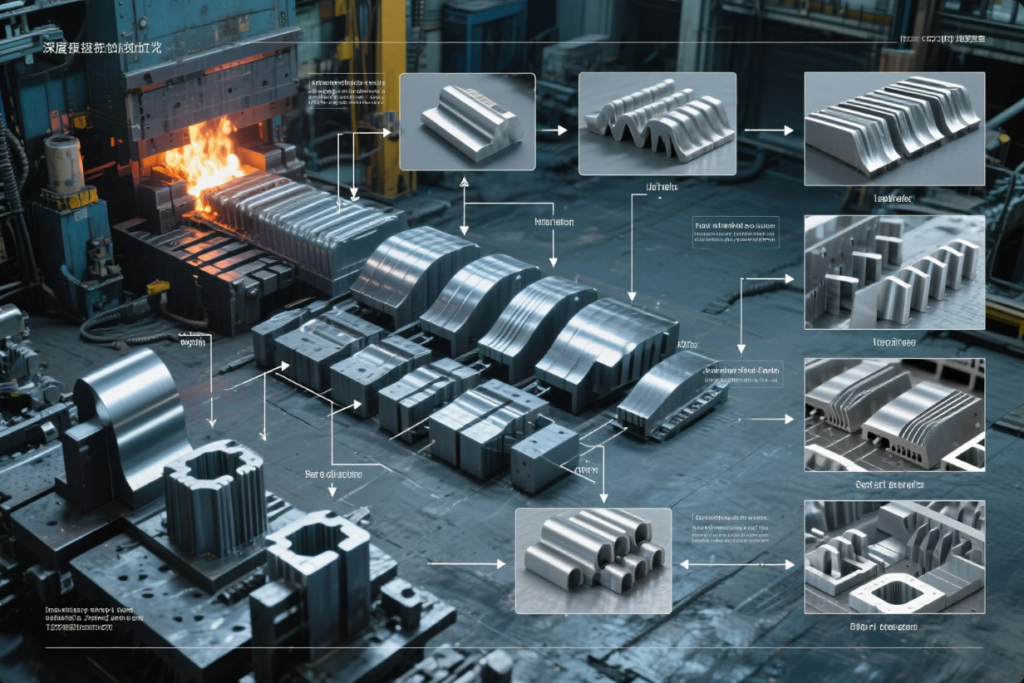

What is deep drawing and how does it differ from standard stamping?

Deep drawing uses punches and dies to stretch sheet metal into 3D hollow shapes, unlike standard stamping that cuts or forms flat profiles. This process is widely used in automotive manufacturing, consumer appliances, medical device fabrication, and aerospace applications.

| Feature | Standard Stamping | Deep Drawing |

|---|---|---|

| Shape | Flat | Deep, hollow |

| Material Flow | Minimal | Intensive, controlled |

| Die Setup | Simple | Multi-stage, progressive |

| Products | Brackets, plates | Cans, housings |

For deep drawing basics, explore The Fabricator and Modern Machine Shop.

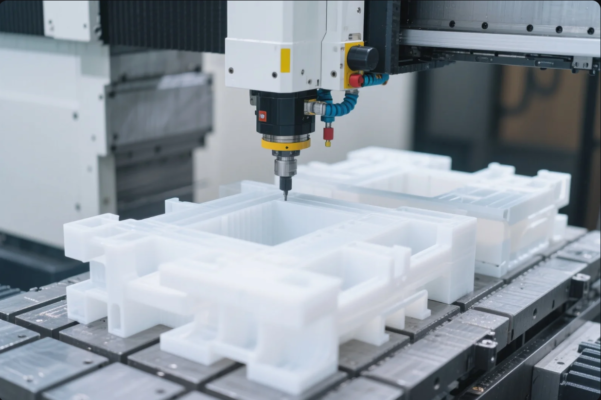

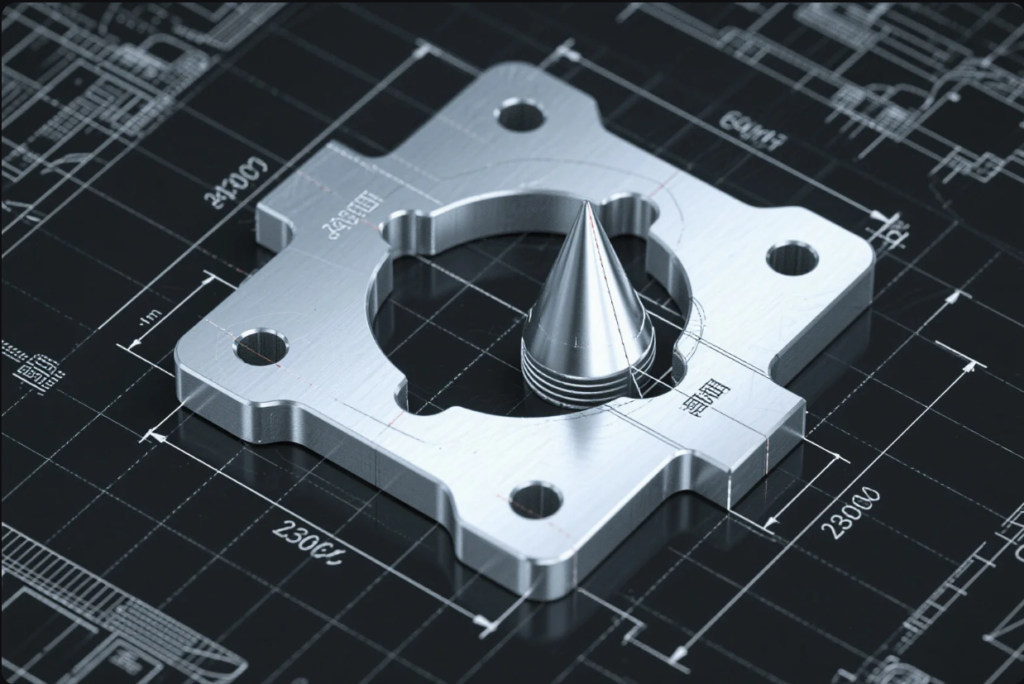

Critical design factors for deep drawing dies

Design elements essential to die performance include:

- Fillet radii ≥5× material thickness to prevent tearing (see ASM International).

- Clearance set at 1.1–1.3× thickness for proper metal flow (refer Steel Dynamics Engineering).

- Blank-holder force \~25–50% of punch force, adjustable with pneumatic or servo systems (learn more at Engineering Toolbox).

- Draw ratio under 2.0 per stage; deeper draws need multiple stages (AutoForm software).

- Lubrication with dry-film, graphite, or phosphate coatings (Henkel).

-

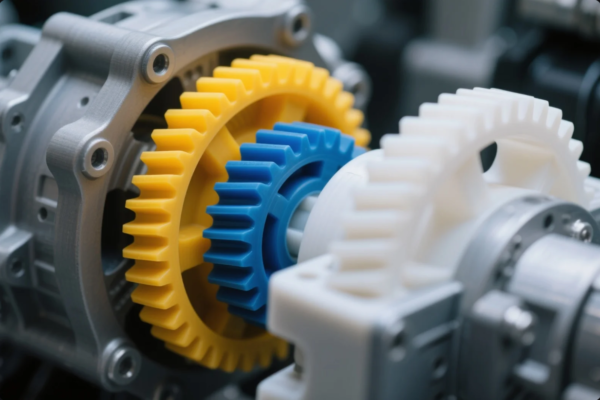

Tool materials:

- Tool steel like D2 or SKD11 from Bohler-Uddeholm.

- Carbide inserts for long runs and stainless applications (Sumitomo Carbide).

- Coated tools using PVD/CVD like TiN from Seco Tools.

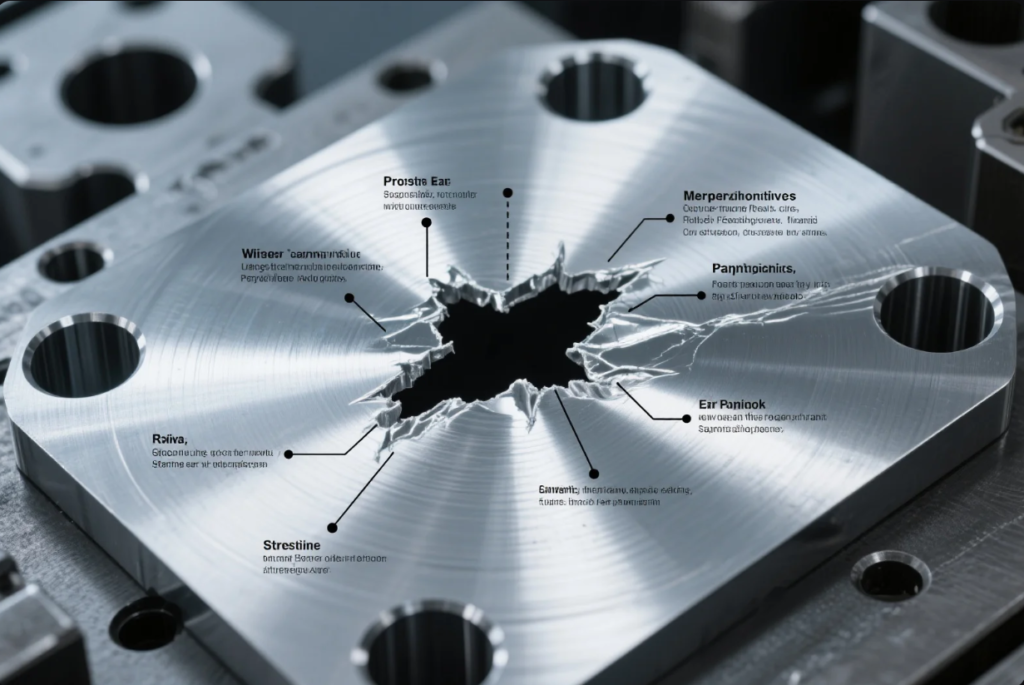

Common deep drawing defects and how to prevent them

| Defect | Cause | Solution |

|---|---|---|

| Wrinkling | Weak blank-holder force | Increase force or add draw beads (Tata Steel) |

| Tearing | Harsh corner radius, low lubrication | Enlarge radii, upgrade lube (Cleveland-Cliffs) |

| Earing | Steel grain direction | Use DDQ grade or rotated blanks |

| Springback | Insufficient plastic deformation | Add restrike station or correct draw procedures |

| Galling | Friction on punch/die surfaces | Apply TiN coatings and high-performance lubricants |

Hands-on defect insights are found at Practical Machinist.

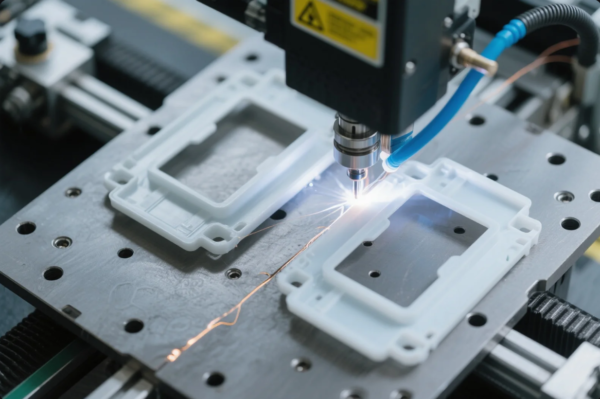

Automotive case study: Fuel filter housing

A Tier 2 supplier for European OEMs experienced 12% rejects due to cracks and shape variance in deep-drawn 304 stainless steel fuel filter housing.

Prime’s solution:

- Simulated forming using AutoForm.

- Enlarged die radius and refined clearance.

- Switched to Bonderite dry-film lubricant by Henkel.

- Added restrike stage for precise ID control.

Result: Defect rate dropped to 1.2%, lead time reduced by 15 days. Product passed rigorous IATF 16949 audits.

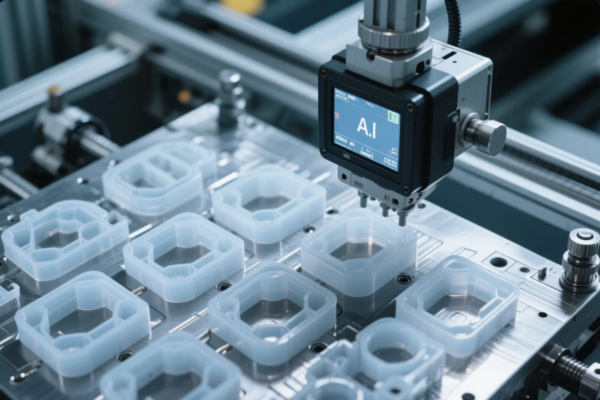

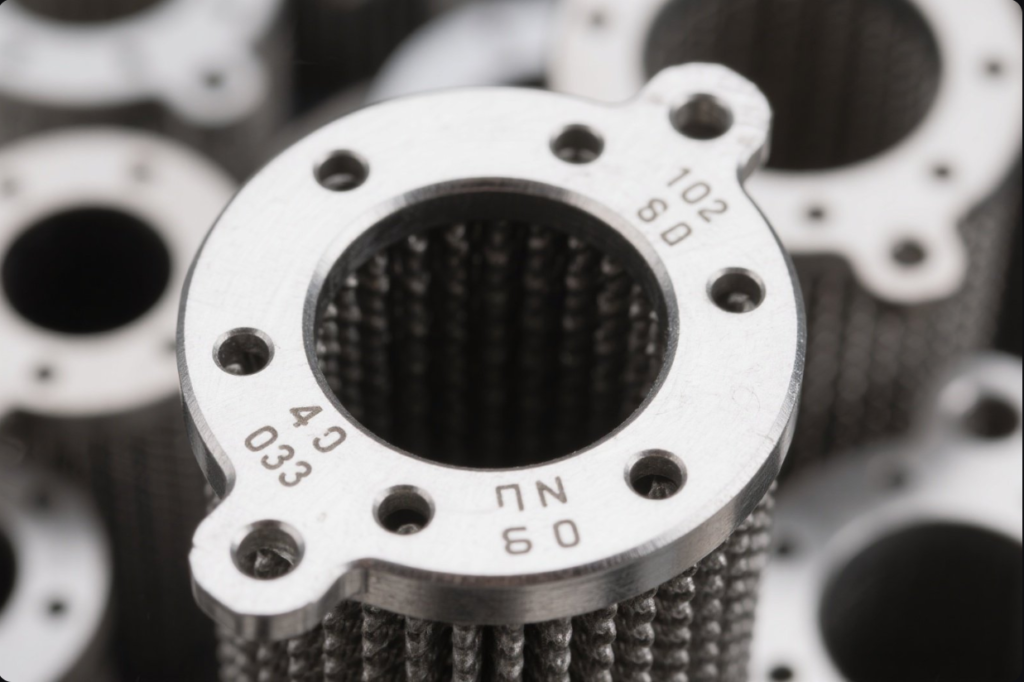

Electronics case study: Lithium battery canisters

For a lithium battery cell project, 3003 aluminum canisters required ±0.02 mm ID tolerance with zero surface blemishes at volumes over 1M units/month.

Prime achieved this by:

- Using polished carbide tools (Ra < 0.2 µm).

- Implementing cryogenic oil-mist lubrication.

- Employing a servo press controlled by Muratec.

- Using TiN-coated punches.

The outcome was a defect rate below 0.5%, expanding output from 200K to 1.2M pcs/month.

15 Deep Drawing RFQ Questions with Answers

-

Do you provide die-forming simulations?

Yes—we use AutoForm and SolidWorks FEA to validate form before build. -

What draw ratio can you handle?

Standard ≤2.0; up to 2.8 with multi-stage tooling. -

Are dies made in-house?

Yes. Design, machining, heat treatment, and inspection are all in-house for quality control. -

What tolerances can you offer?

Standard ±0.05 mm; tight precision ±0.02 mm on critical features. -

How many draw stages are needed per part?

Determined via simulation; typically 2–3 for deep components. -

What materials do you recommend for dies?

D2/SKD11 tool steel for carbon steel; carbide for stainless and aluminum. -

What certifications do you hold?

ISO 9001 since 2007, IATF 16949, and PPAP documentation per OEM standards. -

Is post-processing included?

Yes—deburring, wash, passivation, anodizing, and paint prepping. -

How do you prevent galling on soft metals?

We use TiN punch coatings, graphite-based lubricants (e.g., Henkel), and dry-film methods. -

Do you provide export-approved packaging?

Yes—moisture-proof trays, sealed bags, and foam-lined wooden crates. -

Can I get PPAP samples?

Yes—first-article parts and full PPAP kits are provided free with tool orders. -

What inspection methods do you use?

CMM, 3D vision inspection, and SPC are applied during first batch and production runs. -

What press tonnage capacity do you have?

Presses range from 25 to 300 tons, including electric servo and hydraulic presses. -

What is your typical tooling lead time?

Standard 3–4 weeks; complex progressive tools 5–6 weeks. -

Do you offer after-sales tool support?

Yes—we provide free regrind consultation and fast maintenance when needed.

Deep Drawing FAQ

What materials can be deep drawn?

DC04/01 low-carbon steel, 304 DDQ stainless, 3003 aluminum, and brass/copper alloys.

How do I avoid earing in deep draws?

Use DDQ-grade sheet and orient blanks properly; alternating blanking direction helps.

Can deep-drawn parts be plated or finished?

Yes—they can be nickel plated, zinc-coated, anodized, passivated, or powder coated.

Do you meet ASTM/DIN standards?

Yes. Materials and tolerances conform to ASTM B209, DIN EN 10204, ISO 9001, and IATF 16949.

What's the typical minimum order quantity?

Generally ≥1,000 pcs/year depending on complexity and tooling.

Conclusion

Deep drawing is a precision process requiring balanced die design, force control, lubrication, and simulation. With the right tooling partner like Prime, complex parts can be formed with high accuracy, low scrap, and reliable delivery.

Contact Prime

Need help forming deep-drawn parts?

- 💡 Free DFM review and tooling consultation

- 🧪 AutoForm-simulated design and quoting

- 🛠 ISO-certified tool build with PPAP

- 📦 Packaging and logistics for global shipping

📩 Email: [email protected]

🌐 Website: https://primecustomparts.com