Sustainable Plastic Components: Biodegradable Materials and Circular Solutions?

I’ve heard claims about green plastics. I felt lost in jargon and supplier buzzwords.

Biodegradable materials like PLA, PHA, PBS, and PBAT—coupled with mechanical, chemical, and enzymatic recycling strategies—enable a circular, compliant, and cost-effective value chain. This deep-dive guide covers material science, regulations, certifications, recycling methods, and case studies, helping you make smart procurement decisions with confidence.

📌 Table of Contents

- What are PLA, PHA, and other biodegradable plastics used in molding?

- Mechanical vs. chemical recycling: how circular plastic systems work

- How industry regulations and green certifications influence purchasing decisions

- Case study: How eco‑friendly plastic parts improve brand positioning and CSR

- Advanced Biopolymer Innovations & Future Trends

- Extended Circular Business Models

- FAQs

- Contact Us

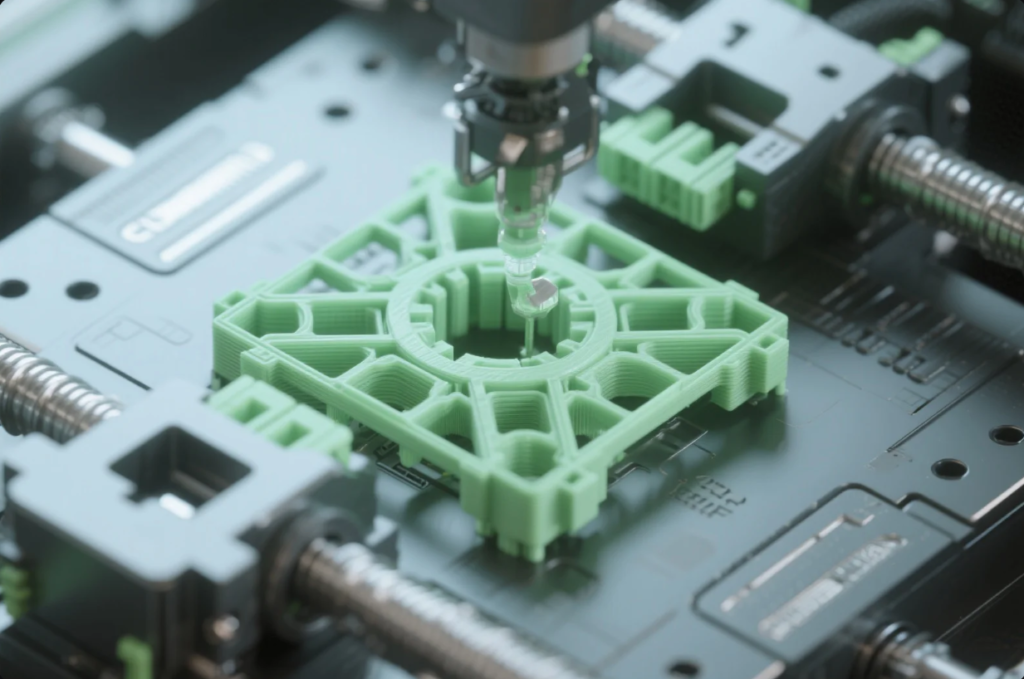

What are PLA, PHA, and other biodegradable plastics used in molding?

Biodegradable plastics differ significantly in biochemistry, performance, and end‑of‑life options.

PLA (Polylactic Acid)

- Derived from renewable feedstocks like corn or sugarcane. NatureWorks offers PLA grades optimized for food contact and injection molding.

- Displays tensile strength around 50–70 MPa and a glass transition temperature near 60 °C.

- Commonly used in cups, trays, 3D printing parts, and disposable packaging. It meets ASTM D6400 (US) and EN 13432 (EU compostability) standards. Companies like Veolia offer industrial composting solutions.

- PLA is brittle—designers often need to add draft angles, radii, or blend it with flexible compounds.

PHA (Polyhydroxyalkanoates)

- Produced via microbial synthesis and fully compostable in soil, water, or marine environments. Danimer Scientific leads the PHA market with packaging and durable part applications.

- Strength measured at 60–80 MPa, Tg \~45–55 °C, making it better suited for medical models, electronics enclosures, and rigid packaging.

- Enzymatic degradation continues post-use; academic research (e.g., in the Journal of Polymers and the Environment) shows promising rates of breakdown under home composting conditions.

PBS, PBAT, PLA Blends, and Other Polymers

- PBS offers heat resistance (\~70 °C), high crystallinity—ideal for cutlery and electronic components. Ineos Bio and Mitsui Chemicals produce commercial-grade PBS.

- PBAT provides flexibility and is widely blended with PLA for mulch films. European Bioplastics details market data and applications.

- PLA blends (30% PLA+PBAT) are cost-effective and compostable—documented by the Circular Bioplastics Alliance.

- Emerging materials: cellulose acetate for eyewear frames, starch-based biopolymers from Novamont for agricultural mulch films.

Mechanical vs. chemical recycling: how circular plastic systems work

Understanding recycling technologies is vital for design and sourcing.

Mechanical Recycling

- Involves grinding, washing, and remelting post-consumer plastics like PET, HDPE, and PP.

- Quality degrades after \~3–5 cycles, per Plastics Recyclers Europe.

- The American Chemistry Council and US EPA outline best practices that Prime follows.

Chemical Recycling

- Breaks down polymers to monomers or syngas, enabling re‑polymerization into virgin-grade resin.

- Loop Industries and Eastman Renew lead innovations in PET and mixed plastics recovery.

- The Ellen MacArthur Foundation and World Economic Forum site chemical recycling as critical to achieving a global circular economy.

Enzymatic Recycling

- Uses biological catalysts to degrade polymers at ambient temperatures.

- Startups like Carbios and research from the [University of Portsmouth] are pioneering PET/PHA-biodegradation techniques.

Comparison Table

| Recycling Method | Process | Resin Quality | Cost | Suitable Applications |

|---|---|---|---|---|

| Mechanical | Shred + remelt | Degrades over cycles | Low | Domestic use, furniture |

| Chemical | Depolymerize → repolymerize | Virgin-like | High | Packaging, medical, branding |

| Enzymatic | Enzyme-driven breakdown | Medium efficiency | Emerging | High-end, compostable materials |

Access Eastman’s case studies to understand carbon reductions achieved through molecular recycling.

How industry regulations and green certifications influence purchasing decisions

Certifications and compliance are key to global market access:

- EN 13432—the EU industrial-compostable standard—certified by TÜV Austria and DIN CERTCO.

- ASTM D6400 (for compostable packaging) and D6868 (for coatings) in the US, managed by ASTM International and certified by BPI.

- RoHS and REACH restrict hazardous substances in electronics and components (per European Commission and ECHA).

- California Proposition 65 demands consumer warnings for chemicals (monitored by CA.gov).

- ISO 14001, audited by BSI, indicates a strong environmental management system.

- GRS (Global Recycled Standard) from Textile Exchange and Cradle to Cradle certification help highlight true recycled content.

Large OEMs require these as prerequisites in their tender specifications.

Case study: How eco‑friendly plastic parts improve brand positioning and CSR

U.S. Appliance OEM

- Partnered with Prime to develop PLA+ABS/rPP trays.

- Gained shelf space in eco-friendly chains (e.g., Whole Foods, IKEA), powered by TerraCycle’s take-back schemes.

- Won “Green Innovation Award” from Green Product Award.

- Achieved ROI in 14 months due to increased visibility and lower returns.

- Brand ESG score rose by 0.8 (via MSCI).

- Prime also ensured full compliance with ASTM, RoHS, and provided TÜV compostability proof.

Medical Device Manufacturer

- Parts molded in PBS and PHA for single-use surgical devices.

- Met ISO 10993 biocompatibility, UL 94 V‑0 flammability, and RoHS substance limits.

- Shipped to EU and Canada with regulatory support.

- Hospital waste systems collaborated for proper disposal—aligned with Swiss regulations.

Advanced Biopolymer Innovations & Future Trends

Biodegradation and Biocatalysis

- Enzymes from Pseudomonas species break down polyesters at ambient conditions. University of Portsmouth research updates reflect this as a future avenue.

- Emerging microbial factories convert food and agricultural waste into biodegradable polymers (studies in Journal of Polymers and the Environment).

Fiber and Composite Technology

- Hemp-, bamboo-, and flax-reinforced bioplastics now used in auto interiors and consumer goods. Research from RISE and VTT leads advances here.

- New formulations aim to meet UL 94 V‑0 flame retardancy—essential for electronics housings.

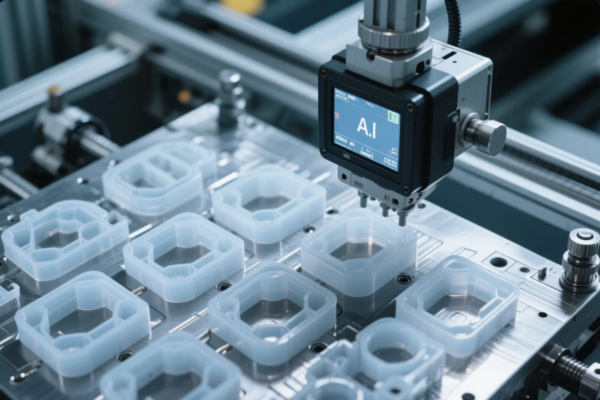

Digital Traceability & Smart Packaging

- RRIDs, QR codes on molded parts improve recycling traceability. Cross-referenced via IBM Food Trust and using blockchain platforms like Circularise.

- These enable brand owners to demonstrate recycled or compostable credentials clearly to end-users.

Extended Circular Business Models

Take-Back Programs

- Dell, HP, and Patagonia run corporate plastics take-back initiatives. TerraCycle collaborates with corporates on closed-loop resins.

- As Eco-Cycle and RePlastify expand, smaller brands can also set up local collection programs.

Design for Disassembly

- Parts engineered for simple snapping or single-material composition reduce recycling complexity.

- A 10–15% recycling yield gain is common when design prioritizes disassembly (GreenBlue Institute data).

FAQs

-

Which biodegradable plastics can Prime injection mold?

— We handle PLA, PHA, PBS, PBAT, and custom blends for strength, flexibility, or compostability. -

Can I source recycled or chemically recycled materials?

— Yes. We offer solutions certified through GRS or chemically recycled via Eastman Renew and Loop technologies. -

Do Prime parts come with environmental certifications?

— We supply all relevant certifications including TÜV, BPI, ISO 14001, ASTM, RoHS, and REACH compliance. -

Is coloration possible for eco-materials?

— Yes, we use eco-safe pigments from Clariant ColorWorks or ColorService to ensure compliance. -

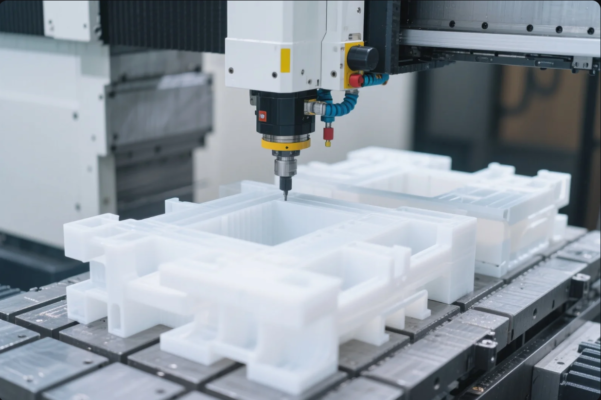

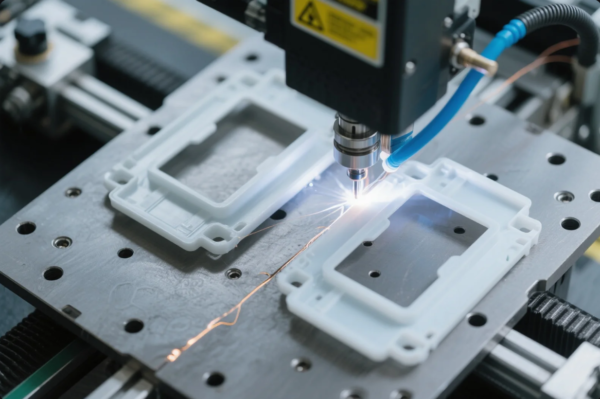

What are typical lead times for molding?

— Standard lead time is 20–30 days post mold approval. Rapid tooling with modular mold inserts can shorten it to 10–15 days. We use DHL, FedEx, and UPS for global shipping.

Contact Us

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Conclusion

By merging biodegradable materials, advanced recycling, thorough compliance, and certified sourcing, you can deliver truly sustainable products that resonate with consumers and regulators.

Partnering with Prime ensures clean supply chains, green brand positioning, and global delivery—without compromising on cost, quality, or speed.