Sheet Metal Fabrication Explained: Balancing Accuracy, Cost, and Speed

Table of Contents

- Introduction: Why Fabrication Method Matters

- Comparing Fabrication Methods: Laser Cutting vs. Stamping vs. CNC Bending

- What Tolerances Can Be Achieved in Sheet Metal Work?

- Managing Costs for Prototypes vs. Mass Production

- Selecting the Best Fabrication Process for Your Application

- FAQs: Sheet Metal Fabrication

- Contact Prime for Expert Fabrication Support

Introduction: Why Fabrication Method Matters

Every fabrication choice affects cost, delivery, and performance. I’ve supported dozens of clients—from aerospace engineers to electronics OEMs—who’ve faced severe delays because of poor fabrication decisions.

A 2022 McKinsey study found 35% of manufacturers lose time or money due to poor sourcing. Avoid this by understanding your options.

This guide helps you:

- Compare laser, CNC, and stamping

- Choose methods based on budget and lead time

- Align accuracy with application needs

- Work efficiently with your metal parts supplier

Comparing Fabrication Methods: Laser Cutting vs. Stamping vs. CNC Bending

| Process | Best For | Accuracy | Setup Time | Volume Suitability |

|---|---|---|---|---|

| Laser Cutting | Prototypes | ±0.05 mm | Very Low | Low to Medium |

| Stamping | Mass Production | ±0.03 mm | High | 10k+ pcs |

| CNC Bending | Enclosures, Frames | ±1° on angles | Medium | 100–2000 pcs |

Laser is ideal for prototyping and low-cost adjustments. CNC bending allows fast 3D shaping. Stamping provides unbeatable per-unit pricing for high-volume runs.

Explore Xometry's or Thomasnet’s method guides to learn more.

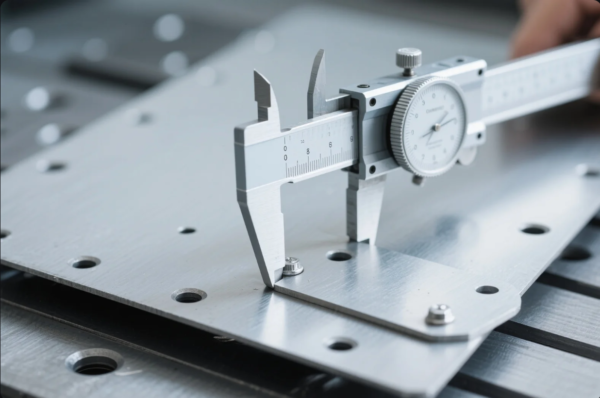

What Tolerances Can Be Achieved in Sheet Metal Work?

Precision depends on material, tooling, and process. Below are standard tolerances from ISO 2768 and ASME Y14.5:

| Feature | Process | Tolerance |

|---|---|---|

| Hole diameter | Laser Cutting | ±0.1 mm |

| Bend angles | CNC Bending | ±1° |

| Coined edges | Stamping | ±0.03 mm |

| Surface flatness | Any | ±0.5 mm/200 mm |

Prime uses Mitutoyo tools, optical comparators, and CMMs to maintain consistent quality, especially for ISO certified metal parts.

Managing Costs for Prototypes vs. Mass Production

Prototype Stage (1–500 pcs)

Mass Production (10,000+ pcs)

- Switch to stamping for cost reduction

- Bundle parts into larger runs

- Optimize carton dimensions

- Use Flexport to plan low-cost freight

Case: One client cut costs from \$4.20 to \$1.25 per part using stamping at volume.

Selecting the Best Fabrication Process for Your Application

Choose Laser Cutting for:

- Complex shapes

- Fast revisions

- Low to medium runs

Choose CNC Bending for:

- Boxes or enclosures

- Consistent folds

- Lower tooling cost

Choose Stamping for:

- Fixed designs

- Tight tolerances

- Mass production (10k+)

Hybrid workflows are also common: use laser/CNC early, then migrate to stamping.

FAQs: Sheet Metal Fabrication

Q: What finishes do you offer?

A: Zinc plating, powder coating, anodizing, RoHS-compliant finishes.

Q: Do you support DDP or FOB terms?

A: Yes. We work with major freight forwarders globally.

Q: Can I customize packaging?

A: We offer foam, shrink wrap, or export cartons with barcode labeling.

Q: What certifications do you follow?

A: ISO 9001, RoHS, AWS D1.1 welding, REACH compliance.

Q: Can I order with staggered delivery?

A: Yes. We support blanket orders and scheduled shipments.

Q: Is Prime a direct manufacturer?

A: Yes. We own 10 production lines in Shandong, China.

Q: Can I get samples before mass production?

A: Absolutely. Samples with material certs are available in 5–7 days.

Contact Prime for Expert Fabrication Support

Prime delivers top-quality industrial parts from China to the world. Our in-house facilities ensure tight control over tolerance, pricing, and delivery.

📩 Email: [email protected]

🌐 Website: https://primecustomparts.com/

🏭 Factory: Shandong, China

📦 Services: Stamping, CNC, Bending, Welding, Packaging, Global Shipping

Request a free quote within 48 hours and discover why hundreds of clients choose Prime.