Sheet Metal Surface Finishes: Improve Durability and Aesthetics

Table of Contents

- Why Surface Finish Matters in Sheet Metal Fabrication

- Powder Coating vs. Anodizing vs. Electroplating: What’s Best?

- How Surface Finish Affects Corrosion Resistance and Product Appearance

- Finish Requirements by Industry: Electronics, Medical, Automotive

- Choosing the Right Surface Treatment for Your Project

- FAQs About Sheet Metal Finishes

- Contact Prime for Surface-Finished Precision Parts

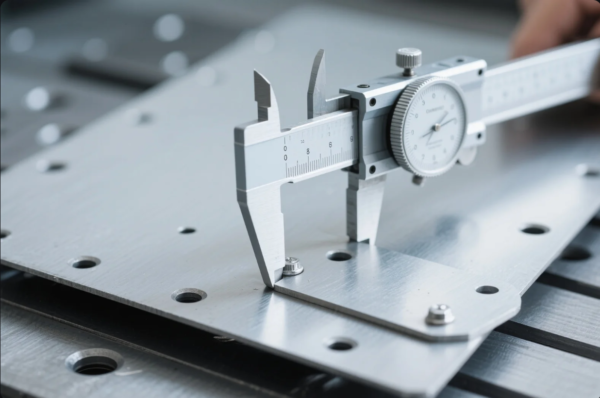

Why Surface Finish Matters in Sheet Metal Fabrication

A metal part is only half-finished without the right surface treatment. I’ve worked with clients who skipped this step—and paid for it later with rust, abrasion, and aesthetic complaints. Don’t let that happen to your project.

Surface finishing improves:

- Corrosion resistance

- Visual appeal

- Wear resistance

- Adhesion of paint or glue

Whether it’s a consumer-facing aluminum enclosure or a bracket hidden inside an engine bay, sheet metal surface finishes determine how your part performs long term. Let’s break down the top three options: powder coating, anodizing, and electroplating.

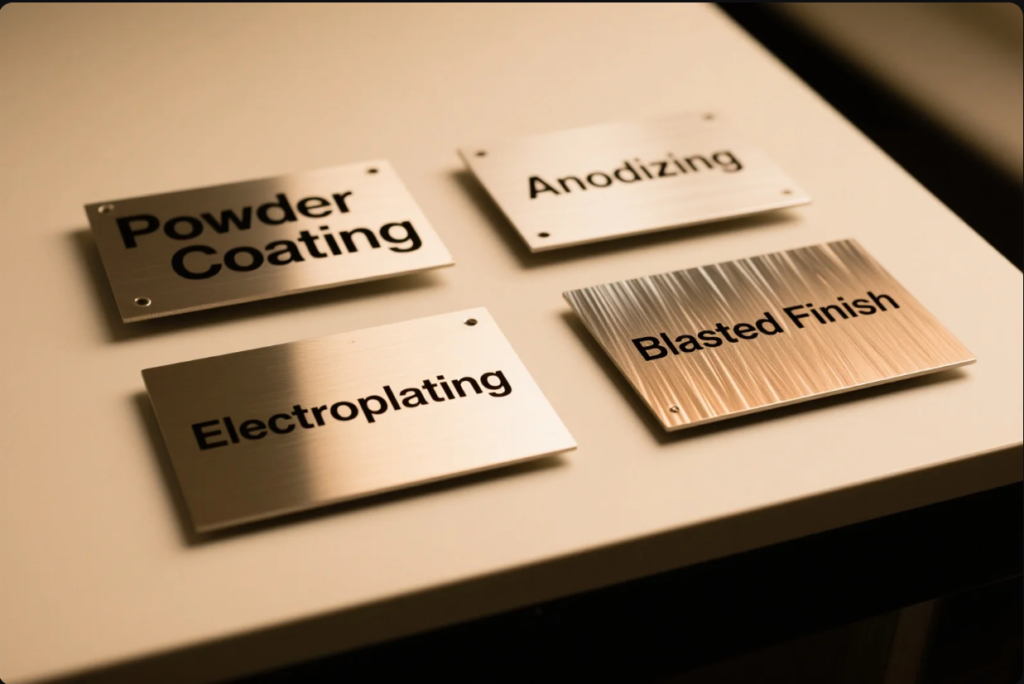

Powder Coating vs. Anodizing vs. Electroplating: What’s Best?

Every finish has its place. The wrong one leads to wasted cost or premature failure. Let’s compare the three most common options.

| Finish Type | Best For | Pros | Cons |

|---|---|---|---|

| Powder Coating | General use, colors, durability | Tough, chip-resistant, eco-friendly (PCI) | Thick layer; limited for tight-fit parts |

| Anodizing | Aluminum parts, electronics | Hard, corrosion-resistant, color-stable (Aluminum Anodizers Council) | Only works on aluminum |

| Electroplating | Steel, brass, zinc components | Thin, conductive, decorative (NASF) | Hazardous waste; costlier for thick coverage |

Powder Coating uses electrostatic application and heat to form a tough finish. It’s used by Protolabs for industrial panels, machinery frames, and appliances.

Anodizing converts the aluminum surface into a corrosion-resistant oxide layer. You’ll see it on MacBooks, LED fixtures, or medical chassis. It’s ideal for anodized aluminum sheet metal suppliers serving the electronics market.

Electroplating deposits a metal layer—chrome, nickel, or zinc—on steel or copper. It’s common in automotive trim, hardware, and tools. Prime offers both decorative and functional plating with RoHS-compliant chemistry.

How Surface Finish Affects Corrosion Resistance and Product Appearance

A great surface finish does more than look good—it protects. I’ve seen untreated steel rust within a week in coastal warehouses. Meanwhile, anodized aluminum parts lasted years without blemish.

Corrosion Resistance

| Finish Type | Salt Spray Rating (ASTM B117) | Best Use Environments |

|---|---|---|

| Powder Coating | 1,000+ hours | Outdoor, marine, automotive |

| Anodizing | 500–2,000 hours (depends on type) | Electronics, cleanrooms, lighting |

| Electroplating | 96–720 hours (zinc-nickel) | Automotive, tools, hardware |

- Powder-coated finishes resist chipping and cracking. Recommended by Sherwin-Williams for exterior enclosures.

- Type II anodizing (decorative) is thinner but looks great. Type III (hardcoat) withstands Mil-A-8625 defense specs.

- Zinc-nickel plating resists corrosion 5–10x longer than traditional zinc. MacDermid Enthone offers custom electrolyte systems.

Appearance and Finish Texture

- Powder Coating: Available in matte, gloss, textured. RAL and Pantone matching supported by Tiger Drylac.

- Anodizing: Produces metallic finishes, ideal for consumer tech. [Clear, black, bronze, red, blue] are common.

- Electroplating: Creates mirror-like chrome or satin nickel. Widely used in decorative plating applications.

Finish Requirements by Industry: Electronics, Medical, Automotive

Electronics

- Key Priorities: Electrical insulation, ESD resistance, cosmetic consistency

- Preferred Finishes: Anodizing (Type II), black powder coat

- Certifications: RoHS, ASTM B117

- Examples: Power supply chassis, LED housings, PCB enclosures

Medical

- Key Priorities: Biocompatibility, cleanability, durability

- Preferred Finishes: Clear anodizing, electropolishing

- Certifications: ISO 10993, FDA CFR 820

- Examples: Syringe pumps, surgical brackets, medical carts

Automotive

- Key Priorities: Corrosion resistance, mechanical strength, decorative effect

- Preferred Finishes: Zinc-nickel plating, chrome plating, powder coat

- Certifications: TS 16949, ASTM D3359, ISO 9227

- Examples: HVAC mounts, bumper reinforcements, battery enclosures

Choosing the Right Surface Treatment for Your Project

Step-by-Step Selection Guide

| Selection Factor | Best Choice | Why It Works |

|---|---|---|

| Aluminum housing, visible | Anodizing | Lightweight, corrosion-proof, sleek |

| Steel bracket, budget | Zinc electroplating | Cheap, protective, thin |

| Outdoor chassis | Powder coating with epoxy base | Weather-resistant, impact-proof |

| Tight tolerance enclosure | Clear anodizing or chemical conversion | Thin, dimensionally stable |

| Decorative trim, chrome look | Bright nickel or chrome plating | Mirror finish, premium appearance |

FAQs About Sheet Metal Finishes

Q1: Can I specify custom RAL or Pantone colors for powder coating? Yes.

Q2: Do you offer matte, gloss, and texture variations? Absolutely.

Q3: Is clear anodizing available for medical devices? Yes.

Q4: What plating thicknesses do you offer? Zinc: 5–25µm, Nickel: 3–15µm.

Q5: How long does powder coat last outdoors? 10+ years.

Q6: Can you combine finishes (e.g., anodizing + laser engraving)? Yes.

Q7: Do you issue RoHS and REACH certificates? Yes.

Q8: Can I request salt spray or adhesion test reports? Yes.

Q9: Do finishes affect part dimensions? Yes. Powder adds 50–150µm.

Q10: Do you offer custom masking or selective finishing? Yes.

Contact Prime for Surface-Finished Precision Parts

📩 Email: [email protected]

🌐 Website: https://primecustomparts.com/

🏭 Location: Shandong, China

📦 Services: Surface Finishing, Fabrication, CNC, Export Logistics

Request a free quote and finish your parts with precision and reliability.