Get Fast Quotes for Sheet Metal Parts: What You Need to Know

Table of Contents

- Why Fast and Accurate Quoting Matters

- How Online Quoting Tools Streamline Sheet Metal Procurement

- What to Include in Your Drawings to Get Accurate Pricing

- Example Turnaround Times: Prototypes vs. High-Volume Orders

- Common Pitfalls to Avoid in the Quoting Process

- FAQs: Sheet Metal Quoting

- Contact Prime for Fast, Certified Quotes

Why Fast and Accurate Quoting Matters

When you’re on a tight timeline, slow or vague quotes create delays. I’ve worked with clients who lost production slots because their suppliers took five days to quote a simple bracket.

In B2B sheet metal sourcing, accurate and quick quoting helps:

- Secure your spot on the production schedule

- Avoid budget overruns

- Accelerate time-to-market

With today’s tools, a quote doesn’t have to take a week. It can take minutes—if you know what to prepare and which platforms to use.

How Online Quoting Tools Streamline Sheet Metal Procurement

Online quoting tools have revolutionized sourcing. Instead of emailing back and forth, buyers upload a CAD file and get a price in minutes. Tools like Xometry Instant Quoting Engine or Fictiv analyze 3D files (e.g., STEP, DXF) and extract manufacturing data automatically.

Advantages of Using Digital Quoting Systems

| Feature | Benefit |

|---|---|

| Instant price feedback | Adjust design to reduce cost live |

| Geometry analysis | Highlights undercuts, tight bends |

| DFM checks built-in | Flags risky features |

| Automated lead time calc | Plan your inventory better |

Prime supports similar online quoting. Clients can upload files via our RFQ form, receive quotes within 24 hours, and confirm orders with a single click.

These platforms often include tolerance checks and surface finish compatibility. For example, RapidDirect integrates plating and coating options during quoting, while Protolabs suggests design tweaks in real-time.

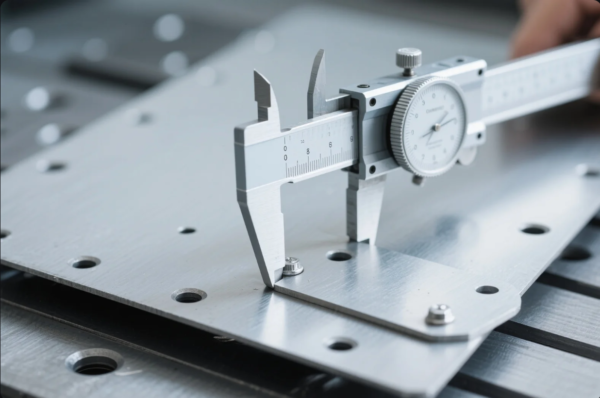

What to Include in Your Drawings to Get Accurate Pricing

I’ve seen RFQs delayed by days just because the drawing was missing a bend radius or hole diameter. Accurate pricing depends on clear documentation. The more complete your data, the faster the quote.

Minimum Information Required

| Drawing Element | Why It Matters | Tools/Standards |

|---|---|---|

| Material Type | Impacts cutting speed, finish choice | ASTM A1008, EN 1.4301 |

| Thickness | Required for bend calculations | Include on both 2D & 3D models |

| Bending Angles | Impacts tooling and setup | Bend Deduction Tables |

| Tolerances | Defines inspection scope & cost | ASME Y14.5 GD\&T |

| Hole Sizes & PCDs | Affects punching & tool paths | Include callouts, drill specs |

| Surface Finish | May add steps: coating, brushing, etc. | ISO 1302 finish codes |

| Quantity Breakdowns | Price changes between 10 / 100 / 1000 pcs | Helps with volume pricing |

Prime’s quoting team checks for all these before generating prices. We also offer free drawing reviews for first-time buyers, especially those sourcing from low-cost regions like China.

Example Turnaround Times: Prototypes vs. High-Volume Orders

Lead times vary widely depending on part complexity, quantity, and finish. I’ve worked with clients who needed a prototype in 48 hours, and others managing three-month rollouts of 50,000 pieces.

Typical Lead Times Comparison

| Order Type | Quantity Range | Lead Time (Days) | Notes |

|---|---|---|---|

| Laser Cut Prototype | 1–10 pcs | 2–5 | Faster with local CNC capability |

| Bent Enclosure | 5–50 pcs | 5–10 | Depends on setup, bend complexity |

| Painted Assembly | 50–500 pcs | 10–15 | Includes powder coating or anodizing |

| Mass Production | 1000–50k pcs | 20–45 | Includes stamping dies or custom tools |

Turnaround also depends on how fast you approve the quote and provide production-ready drawings. That’s why online systems like RapidDirect or Geomiq are preferred by time-sensitive teams.

Common Pitfalls to Avoid in the Quoting Process

Frequent Quoting Mistakes

| Mistake | Consequence | Solution |

|---|---|---|

| Missing Material or Thickness | Incorrect pricing or reject | ASTM A1008 |

| No Tolerance Indicated | Default assumption may increase cost | ISO 2768-mK |

| Uploading Raster Images (JPG) | Slows quoting process | Use STEP files |

| No Finish Specified | Missing coating step or wrong surface | ISO 1302 |

| Inconsistent Drawing Data | Confuses system and team | Match CAD and 2D versions |

| Forgetting Volume Breakdown | Misses volume pricing opportunities | Quote for 10 / 100 / 1000 pcs |

Helpful Tools: CAD Exchanger, TraceParts, Xometry tolerance guide

FAQs: Sheet Metal Quoting

Q1: What file formats do you accept for RFQs? STEP (.stp), DXF, DWG, PDF.

Q2: Can you quote with just a sketch? Yes, but drawings are better. Try Fusion 360.

Q3: Do you offer bundled quotes with finish and assembly? Yes. See our capabilities.

Q4: How soon will I get a quote? 24–48 hours, faster on request.

Q5: Do you support NDA for quoting? Yes.

Q6: Can you quote from SolidWorks or Inventor files directly? Yes, we support both SolidWorks and Inventor.

Q7: Are there minimum order quantities? No MOQ for laser cut parts.

Q8: What materials are stocked? 5052, 6061, 304SS, SPCC, GI.

Q9: Can I get multiple configurations quoted? Yes. Please label clearly.

Contact Prime for Fast, Certified Quotes

📩 Email: [email protected]

🌐 Website: https://primecustomparts.com

📍 Location: Shandong, China

⚙️ Services: Quoting · Cutting · Bending · Welding · Finishing · Assembly

🕒 Turnaround: 48–72 hr quotes, 3–10 day express production

Get a free RFQ review, instant pricing advice, and professional support from our bilingual team. We reply within 24 hours.