TEMPLATE_START

What Is the Front Metal Part of a Car Called?

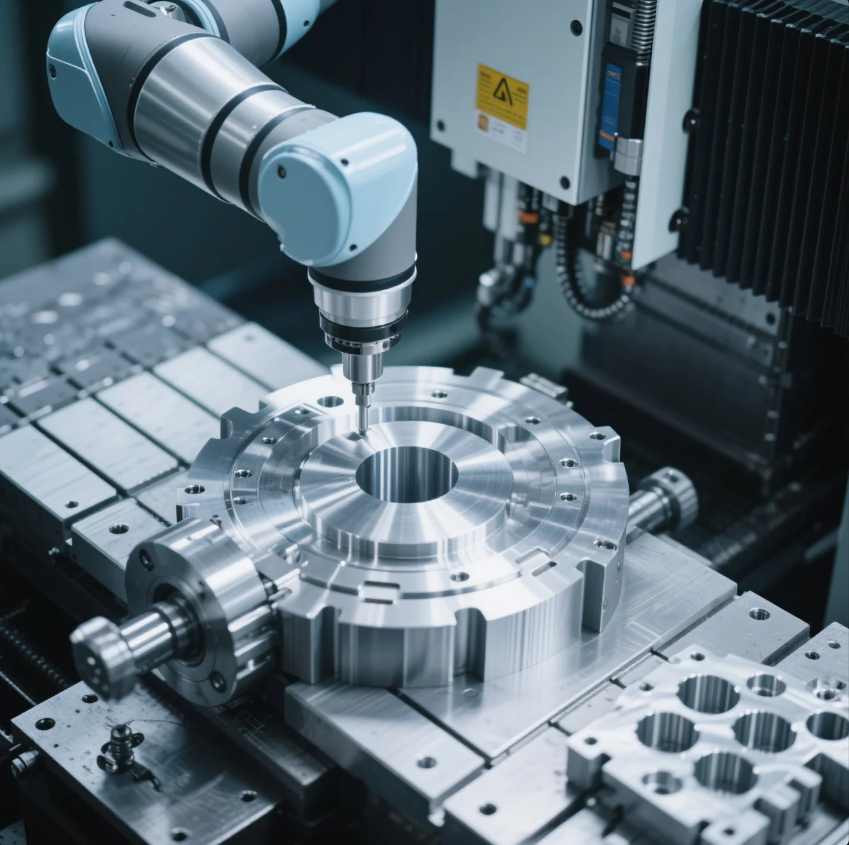

The front end of your car contains several critical metal components that protect the engine and define the vehicle's appearance. At our factory, we stamp these parts daily for global automakers.

Snippet paragraph: The primary front metal section of a car is called the bumper assembly, consisting of the bumper cover, reinforcement beam, grille, and supporting brackets - all designed for impact absorption and pedestrian safety.

Let's examine this structural system's components in detail.

LOOP_START

What Composes a Car's Front Bumper System?

Modern bumper systems integrate multiple metal and plastic elements that work together during collisions.

Snippet paragraph: A complete front bumper assembly includes a steel reinforcement bar (16-18 gauge), aluminum crush cans, stamped steel brackets, and a plastic cover - engineered to meet specific crash test standards.

Bumper Structure Breakdown

Structural Components

- High-strength steel reinforcement beam (2-3mm thickness)

- Aluminum energy absorbers (6061-T6 alloy)

- Galvanized steel mounting brackets

- Steel radiator support panel

Material Comparison

| Part | Material | Thickness | Purpose |

|---|---|---|---|

| Reinforcement | DP600 steel | 2.5mm | Main impact resistance |

| Brackets | Mild steel | 1.8mm | Mounting points |

| Crush boxes | Aluminum 6061 | 3.0mm | Controlled deformation |

Manufacturing Processes

- Progressive die stamping for steel reinforcements

- Hydroforming for aluminum components

- Robotic welding with 0.5mm precision

- E-coating for corrosion protection

LOOP_END

LOOP_START

What Other Metal Parts Surround the Front Bumper?

Several adjacent metal structures connect to the bumper system, forming the complete front-end module.

Snippet paragraph: Surrounding the bumper are the hood (aluminum/steel), fenders (galvanized steel), radiator support (stamped steel), and headlight mounts (die-cast aluminum) - all requiring precise fitment within 2mm tolerances.

Front-End Assembly Composition

Structural Elements

| Component | Common Materials | Joining Method |

|---|---|---|

| Hood | Aluminum 5182 / Steel HSLA | Hemming |

| Fenders | Galvanized steel 340/590DP | Spot welding |

| Radiator support | Steel 1.2mm | MIG welding |

Manufacturing Specifications

| Process | Tolerance | Equipment Used |

|---|---|---|

| Stamping | ±0.8mm | 800-ton presses |

| Welding | ±1.2mm | Robotic cells |

| Assembly | ±2.0mm | Jig fixtures |

Corrosion Protection Methods

- Cathodic dip coating for internal cavities

- Zincrometal pre-treated steel

- Seam sealing of all joints

LOOP_END

LOOP_START

How Do Bumper Materials Differ Across Vehicle Classes?

From compact cars to heavy trucks, bumper construction varies significantly based on safety requirements.

Snippet paragraph: Economy cars use thinner gauge steels (1.2-1.8mm) with simplified designs, while luxury vehicles employ aluminum alloys (5000/6000 series) and premium SUVs incorporate ultra-high-strength steels (1200MPa+) in critical zones.

!

Vehicle Class Comparisons

Material Usage by Segment

| Vehicle Type | Bumper Beam Material | Impact Standard |

|---|---|---|

| Subcompact | 340MPa steel | 2.5mph test |

| Luxury sedan | Aluminum 6061 | 5mph test |

| Full-size truck | Boron steel 1500MPa | Heavy-duty |

Cost vs Performance Analysis

| Material | Part Cost | Weight | Energy Absorption |

|---|---|---|---|

| Mild steel | $ | Heavy | Good |

| Aluminum | $$ | Light | Excellent |

| CFRP | $$$ | Very light | Superior |

Emerging Technologies

- Hybrid aluminum-steel constructions

- Hot-stamped ultra-high-strength steels

- Composite reinforcement inserts

LOOP_END

Conclusion

The front metal section of a car combines protective and structural elements engineered to precise standards - from economical steels to advanced alloys based on vehicle requirements.

TEMPLATE_END