CNC Parts

The world's leading supplier of metal CNC parts.

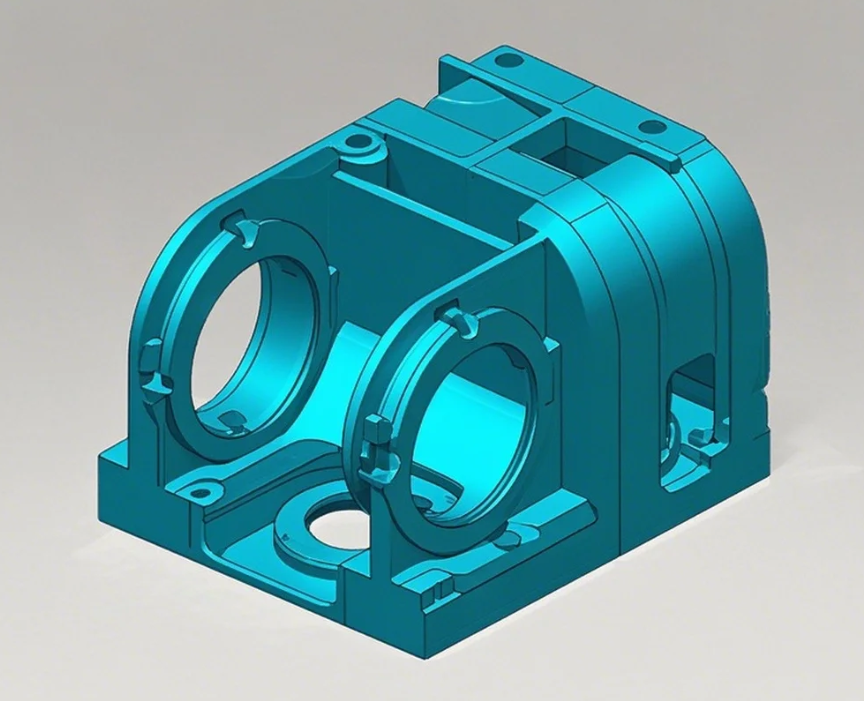

Customized CNC parts

Customized metal CNC parts can not only improve the quality and reliability of products, but also meet the complex needs of different industries through precision machining. Whether it is single-piece customization or mass production, we can provide high-quality CNC machining services to help your project to achieve more efficient production and more accurate application.

Table Of Contents For This Page

At Prime, we provide you with professional service and high-quality products.

Application fields of customized metal CNC parts

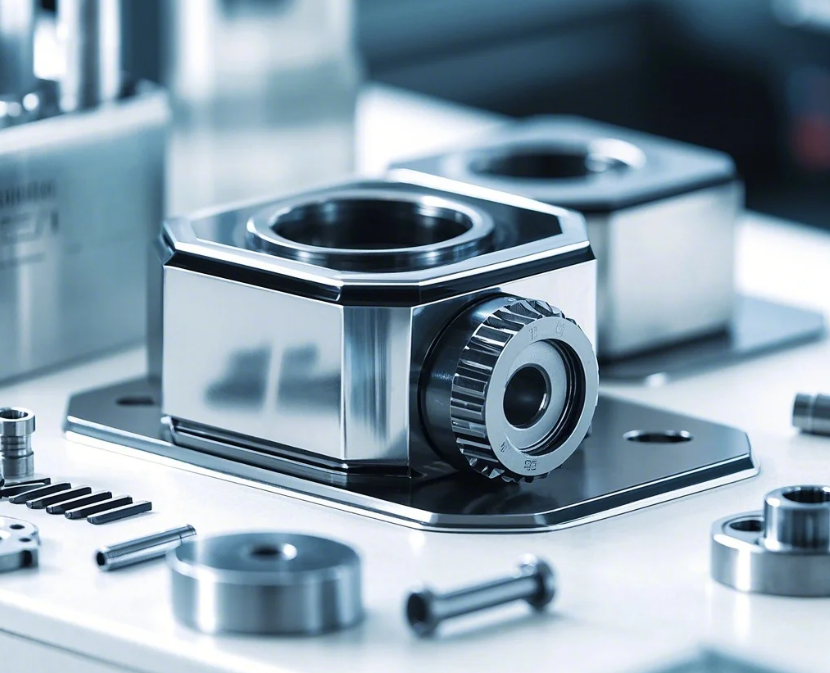

Customized metal CNC parts are an indispensable part of industrial manufacturing, which are widely used in many fields, such as automobile manufacturing, aerospace, electronic products, precision instruments and mechanical equipment. With its high degree of precision and reliability, CNC machining technology has become the mainstream manufacturing process to meet the needs of modern industry.

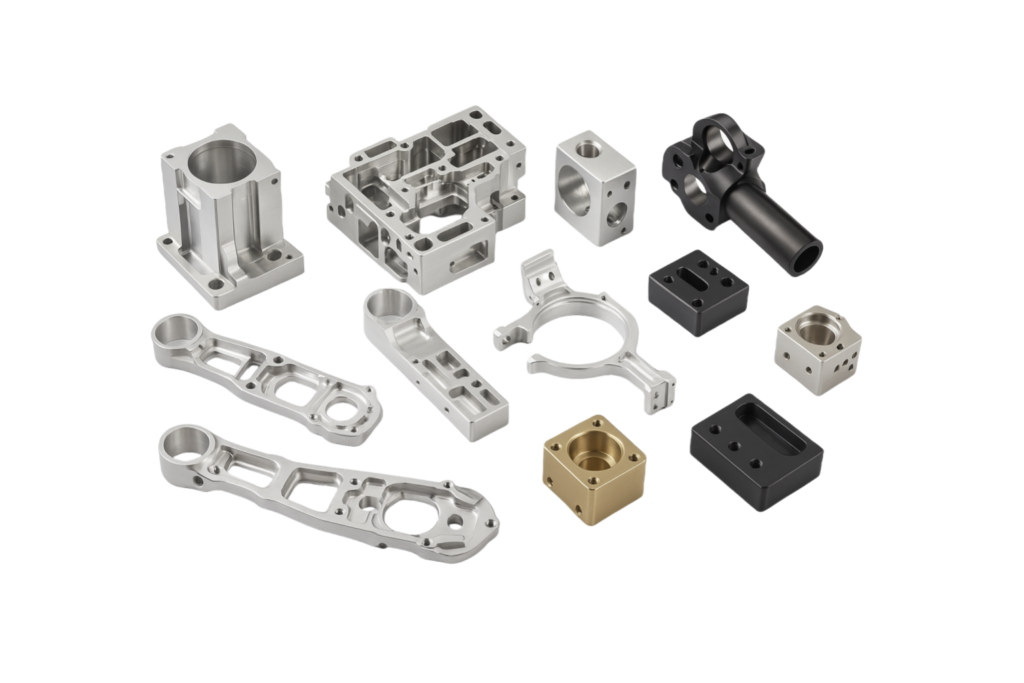

General Hot Selling Products

Customized CNC parts can be divided into several main types according to different machining processes, and each process has its unique characteristics and application fields. The following are some common CNC part types grouped by process and their characteristics and areas of application:

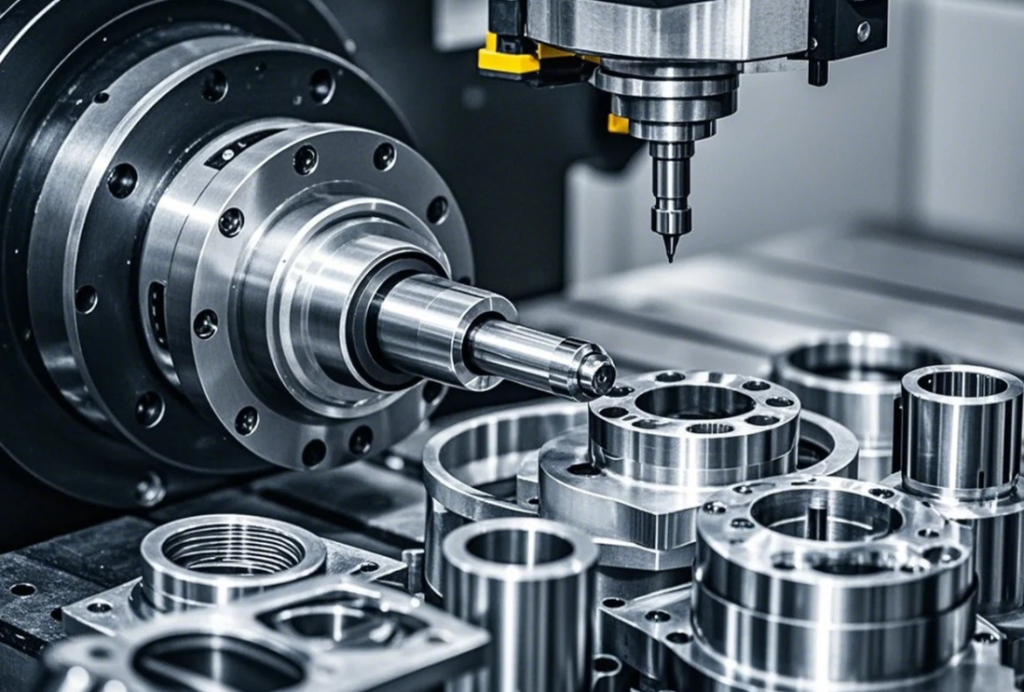

CNC turning parts

- Features:

- Mainly through the rotation of the workpiece and fixed cutting tools for cutting, suitable for processing circular, shaft, hole and other parts.

- Fast processing speed, suitable for mass production.

- High precision, high Surface finish.

Applications:Engine parts, shafts, gears, etc. in automobile manufacturing. Aircraft engine parts, landing gear parts, etc. . Mechanical equipment bearings, gears and other power transmission parts. Electronic connectors, electronic enclosures, etc. .

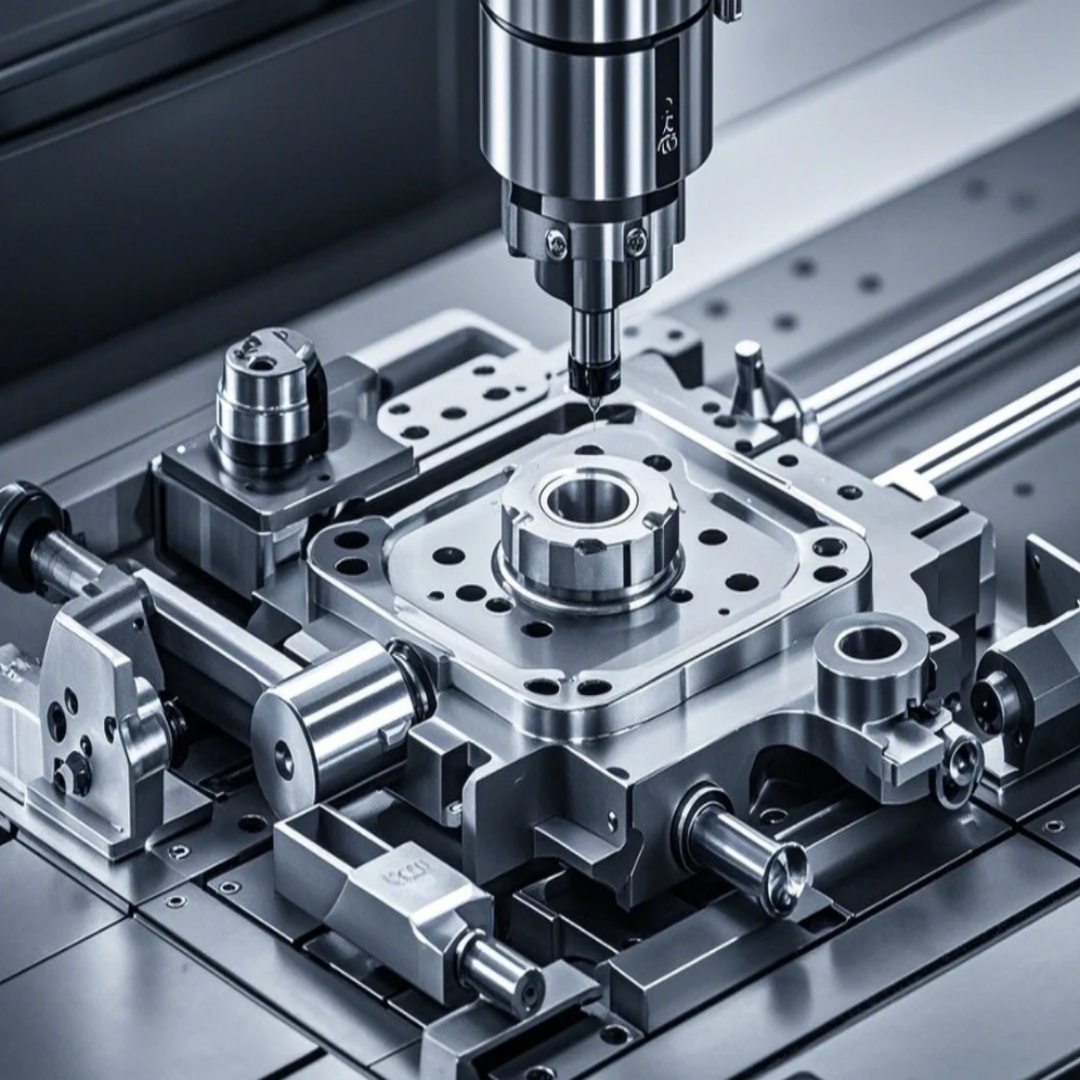

Parts for CNC milling

- Features:

- The use of rotating tools to cut the workpiece, you can machine complex geometric shapes, usually plane, groove, curved surface, etc. .

- Suitable for more complex parts, and can process more than one surface at the same time.

- High machining accuracy, can reach the micron level.

Applications:Plastic mold, metal mold and so on in the mold manufacture. Complex aerospace components and spacecraft assemblies. Precision instruments such as medical instruments and instrument casings. Automobile industry in the engine parts, transmission parts, etc. .

CNC grinding of parts

- Features:

- Very high Surface finish and dimensional accuracy can be achieved by grinding the surface of the workpiece with a high-speed rotating abrasive tool.

- It is suitable for the parts with high hardness and complex shape.

- Mainly used for surface finishing, can effectively improve the surface quality of parts.

Application:High precision tools such as moulds, cutting tools, bearings, etc. . Automotive engine parts, brake system components, etc. in the automotive industry. Precision electronic parts of the surface processing, high-precision aviation parts.

CNC Electrical discharge machining (EDM) parts

- Features:

- The electrode is used to process materials with high hardness or complex shape by means of EDM.

- Able to process traditional machining is difficult to achieve complex holes, small structures or hard materials.

- Suitable for precision detail machining, but the production speed is relatively slow.

Application:Complex mold, cooling channel, precision hole processing, aero-engine parts, high precision hole processing, automotive gear, Cam and other complex parts, precision parts and hole processing in the electronics industry.

CNC laser cutting parts

- Features:

- Laser cutting using high-intensity laser beam to heat the material surface to the molten state, through the airflow will be blown away the molten metal, cutting materials.

- Suitable for cutting sheet metal, cutting edge smooth, no need for subsequent processing.

- High machining accuracy, suitable for complex shapes and details of the processing.

Applications:Automotive shells, interior parts, steel components, building decorations and other architectural structures, electronic metal shells, electronic components, aerospace light structural parts, cabin components.

CNC laser marking parts

- Features:

- The surface of the material is marked by a laser beam, which can be words, patterns, two-dimensional codes, etc. .

- No need for consumables, marking clear, durable, applicable to metal, plastic, glass and other materials.

- High speed, high precision, widely used in product tracking and identification.

Applications:Mobile phones, computers and other products identification and two-dimensional code, medical equipment marking, auto parts number and tracking, consumer goods brand identity, product serial number, etc. .

CNC water jet cutter cutting parts

- Features:

- Through high-pressure water with or without sand to carry out cutting, can cut a variety of materials, including metal, plastic, stone, glass, etc. .

- No heat affected zone, suitable for cutting materials with different thickness.

- Suitable for complex shape, fine cutting, smooth edge, reduce thermal deformation.

Applications: Body Cutting, precision parts processing and other automotive manufacturing, Stone, tile cutting and other construction industries, sculpture and decoration of fine cutting, high-precision parts processing, etc. .

In Summary

Ach CNC process has its unique advantages, select the appropriate processing method can help to achieve efficient, accurate part customization. According to the parts of the material, shape, precision requirements and production volume and other factors, you can choose the appropriate process to meet your needs.

The Process Flow & Duration Estimation

The production process of metal CNC parts is precise and efficient, ensuring that each part can meet the strict requirements of customers. Our production process includes the following key steps:

Step 1: Design and modeling

Before starting production, our engineering team works closely with customers to ensure that each part is designed to meet their needs. Through the professional CAD software, create accurate three-dimensional model, and detailed analysis and optimization.

Step 2: Choose the ingredients

We provide a variety of metal materials for customers to choose, including aluminum alloy, stainless steel, copper and so on. According to the specific requirements of the parts, select the most appropriate materials to ensure that the parts have the best performance and durability.

Step 3: Programming for CNC machining

After selecting the right material, we will write a detailed CNC machining program. Through computer numerical control technology, precise control of each tool cutting path and depth, to ensure the accuracy and consistency of parts.

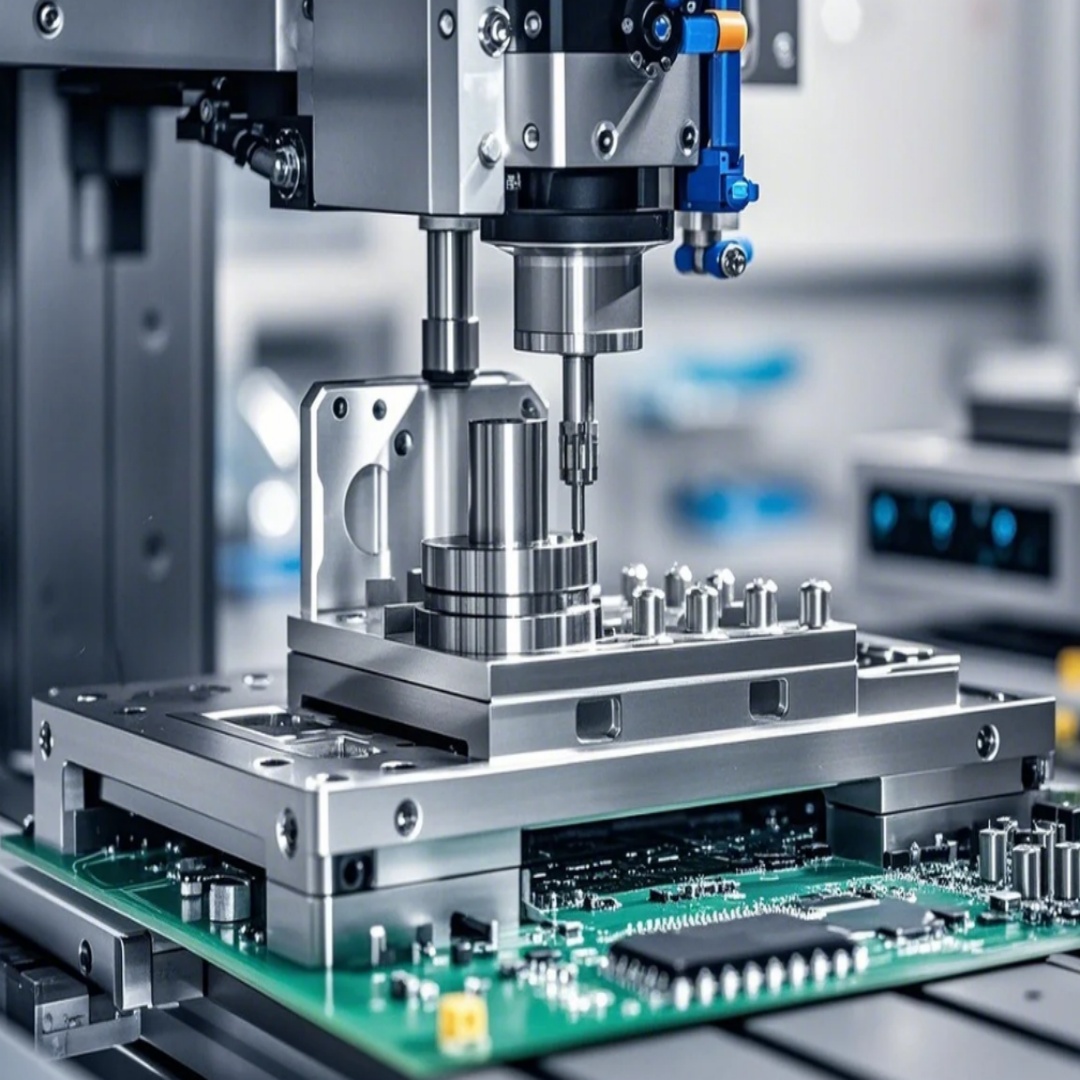

Step 4: Processing

Precision machining is carried out on CNC machine tools. The machine automatically cuts and carves according to the programming instructions, and completes the shape and detail processing of the parts. The whole process without human intervention, to ensure that each part is accurate.

Step 5: Quality inspection

After machining, all parts will be subjected to strict quality inspection. We use high-precision measuring tools to perform a comprehensive inspection of dimensions, tolerances and surface quality to ensure compliance with design specifications.

Step 6: Post treatment and surface treatmen

According to customer requirements, the parts can be a variety of post-treatment, including polishing, spraying, anodizing and other surface treatment. This not only improves the appearance of the parts, but also enhances its corrosion resistance and wear resistance.

Step 7: Final inspection and packing

After the final quality inspection of all metal CNC parts, they will be packed to ensure the safety of the parts during transportation. We use high quality packing materials to ensure that the parts are in good condition during transportation.

Step 8: Delivery of finished product

Upon completion of all inspection and post-processing, the castings will become the final product, ready to be delivered to the customer or used for assembly.

Want to know how to compress lead times?

In order to shorten the production and delivery cycle, we suggest that you tell us your needs in detail, and we will adjust the strategy flexibly according to your requirements to ensure your production and help you succeed!

The Common Pitfalls When Purchasing

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

- Improper material selection: improper material selection may lead to CNC parts can not reach the strength, corrosion resistance and other performance requirements, affecting the service life.

- Poor design: immature design will lead to CNC parts production difficulties, increased costs, delivery delays.

- Supplier is not reliable: some unprofessional suppliers may not be strict in quality control, resulting in substandard products or delivery is not timely.

Raw materials for CNC parts

The raw materials of CNC (computer numerical control) parts usually depend on the application, requirements, and required mechanical characteristics of the part. Here are some common raw materials for CNC machining:

Aluminum

Commonly used in the manufacture of light components, with good mechanical properties and corrosion resistance. Applicable to aviation, automotive and electronics industries.

Stainless steel

Has excellent corrosion resistance and strength, suitable for the manufacture of the need to withstand high temperatures and harsh environments.

Carbon Steel

For the manufacture of high-strength components. Carbon Steel hardness and wear resistance is good, common in engineering machinery and tool manufacturing.

Titanium

A copper alloy with good electrical and thermal conductivity and corrosion resistance; used in the manufacture of electronic component and precision instruments.

Plastics (e.g. POM, nylon)

Suitable for manufacturing lightweight and friction-resistant components, widely used in automobiles, medical devices, and consumer electronics.

Alloy Steel

By adding different alloying elements, improve the strength of steel, hardness and wear resistance, suitable for high requirements of mechanical parts.

Aluminum bronze

Has good corrosion resistance and wear resistance, commonly used in the marine environment components.

Different CNC parts may require the selection of appropriate materials based on their function and the environment in which they are used. By selecting different raw materials, you can optimize product performance and extend its service life.

A Brief Self-Nomination, Why Choose Prime?

Choose Us, you will get reasonable prices, high quality, on-time delivery of metal CNC parts solutions.

Experience: We have more than 30 years of metal CNC parts production experience, can provide the industry with high-quality customized metal CNC parts.

Professional team: Our Engineering team is familiar with metal CNC parts production technology, can provide accurate design and production services.

Quality assurance: We are ISO 9001 certified to ensure that each metal CNC part meets the highest quality standards.

Rapid Response: We are committed to providing fast sample production and production cycle, to ensure that your needs can be met in a timely manner.

Global Services: No matter where you are, we can provide you with quality services to ensure the smooth progress of your business.

Get in touch

Custom Hardware Parts Made Easy

Share detailed information about your needs, including drawings, reference images, and any specific ideas or specifications you have in mind.

Based on your requirements and design, we’ll provide a custom solution and send you a detailed quote within 24 hours.

Once you approve the design and quote, we’ll begin mass production and take care of the shipping, ensuring timely delivery.

Get a Free Quote

Reach out to us for a free quote and expert advice on your custom hardware needs. At Prime, we’ll provide the right solution for your project, ensuring quality and precision every step of the way.