TEMPLATE_START

What Are Die Casting Parts and Why Are They Essential?

In our 30 years of metal fabrication, we've produced over 5 million die-cast components for industries ranging from automotive to consumer electronics. These precision parts solve critical manufacturing challenges.

Snippet paragraph: Die casting parts are metal components created by forcing molten metal under high pressure into reusable steel molds - producing dimensionally accurate, smooth-surfaced parts at rates up to 200 shots per hour with minimal post-processing.

Understanding die casting's capabilities helps determine when it's the optimal manufacturing solution.

LOOP_START

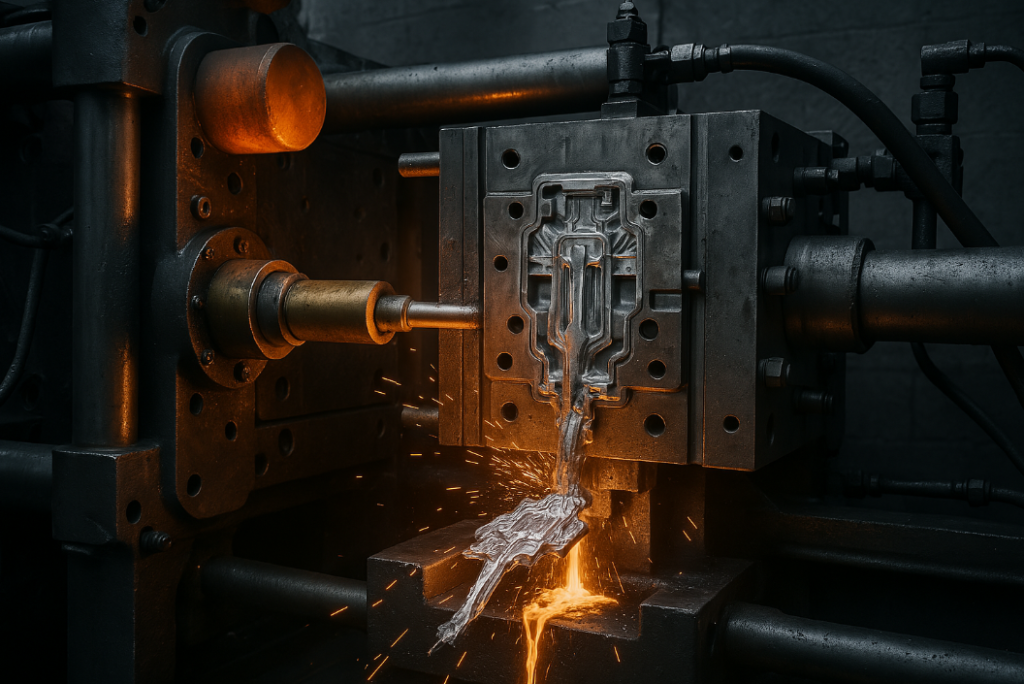

How Does the Die Casting Process Work?

Die casting transforms liquid metal into finished parts through meticulously controlled steps.

Snippet paragraph: The process involves injecting molten aluminum, zinc, or magnesium alloys at 10-175 MPa pressure into temperature-controlled steel dies, with cycle times ranging from 30 seconds to 2 minutes depending on part size and complexity.

The 5-Stage Die Casting Cycle

| Stage | Duration | Key Parameters | Equipment |

|---|---|---|---|

| Clamping | 5-15s | 200-4000 tons force | Die casting machine |

| Injection | 0.01-0.5s | 10-175 MPa | Shot sleeve |

| Cooling | 10-60s | Die temp 150-250°C | Cooling channels |

| Ejection | 3-8s | Ejector pin force | Ejector system |

| Trimming | 2-5s | Shear clearance | Trimming press |

Material Flow Characteristics

| Alloy | Melting Point | Fluidity | Shrinkage Rate |

|---|---|---|---|

| A380 | 565°C | Excellent | 0.7% |

| ZA-8 | 404°C | Good | 1.1% |

| AZ91D | 598°C | Fair | 1.2% |

Critical Process Controls

- Gate velocity: 30-50 m/s for optimal filling

- Die temperature gradient: ±5°C tolerance

- Plunger acceleration profile: 3-stage ramp-up

LOOP_END

LOOP_START

What Are the Main Advantages of Die Casting Parts?

Die casting outperforms other methods for specific applications.

Snippet paragraph: Compared to sand casting, die casting provides 10x better dimensional accuracy (±0.025mm), 3x faster cycle times, and superior surface finishes (1.6μm Ra typical) - while enabling complex geometries unreachable through machining.

Performance Benchmarking

| Characteristic | Die Casting | Sand Casting | CNC Machining |

|---|---|---|---|

| Tolerance | ±0.025mm | ±1.5mm | ±0.01mm |

| Surface Finish | 1.6μm Ra | 12.5μm Ra | 0.8μm Ra |

| Wall Thickness | 0.5-5mm | 3-25mm | No limit |

| Production Rate | 200/hr | 20/hr | 1-5/hr |

Economic Comparison

| Factor | Die Casting Advantage |

|---|---|

| Labor Cost | 60% lower than machining |

| Material Waste | <15% vs. 50% machining |

| Tooling Life | 100,000+ shots |

| Post-Processing | Often eliminated |

Unique Capabilities

- Thin walls: As low as 0.5mm

- Near-net-shape: 95% final dimension

- Integrated features: Threads, knurls, logos

LOOP_END

LOOP_START

Which Industries Use Die Casting Parts Most?

Nearly every engineering sector benefits from die casting's advantages.

Snippet paragraph: Automotive (38% of market) uses die cast transmission cases and brackets; electronics (27%) requires heatsinks and housings; while appliances (18%) incorporate die cast frames and mechanisms - showing remarkable versatility across sectors.

Industry Application Matrix

| Sector | % Usage | Common Parts | Material Preferences |

|---|---|---|---|

| Automotive | 38% | Gearboxes, brackets | A380, ADC12 |

| Electronics | 27% | Housings, connectors | AZ91D, ZA-8 |

| Appliances | 18% | Motor frames | A360, A413 |

| Industrial | 17% | Hydraulic components | A390, No.2 Alloy |

Emerging Applications

| Technology | Die Casting Solution |

|---|---|

| EVs | Battery enclosures, motor housings |

| 5G | Antenna bodies, RF shields |

| IoT | Sensor casings, mounting brackets |

Material Innovation Trends

- Hypereutectic aluminum (A390) for wear resistance

- High-thermal-conductivity alloys for cooling

- Recycled-content alloys meeting OEM specs

LOOP_END

Conclusion

Die casting parts deliver unmatched precision and efficiency for medium-to-high volume metal components across virtually every engineering sector.

TEMPLATE_END