TEMPLATE_START

How Are Casting Parts Manufactured Step-by-Step?

At our foundry, we've produced over 2 million casting parts by perfecting these key manufacturing stages. The casting process transforms molten metal precisely into functional components.

The casting process involves pattern creation, mold preparation, metal melting, pouring, solidification, removal, and finishing - with exact steps varying based on casting method (sand, die, investment, or centrifugal) and material specifications.

Let me walk you through the complete production journey our factory uses.

What Are the Essential Steps in Sand Casting Production?

Sand casting remains the most versatile method for prototype and medium-volume production.

To make sand casting parts: 1) Create pattern 2) Prepare sand mixture 3) Make mold 4) Melt metal 5) Pour molten metal 6) Cool 7) Break mold 8) Remove part 9) Finish surfaces - typically achieving ±1.5mm tolerance on production runs.

Detailed Sand Casting Process Breakdown

| Step | Time Required | Key Equipment | Quality Control Check |

|---|---|---|---|

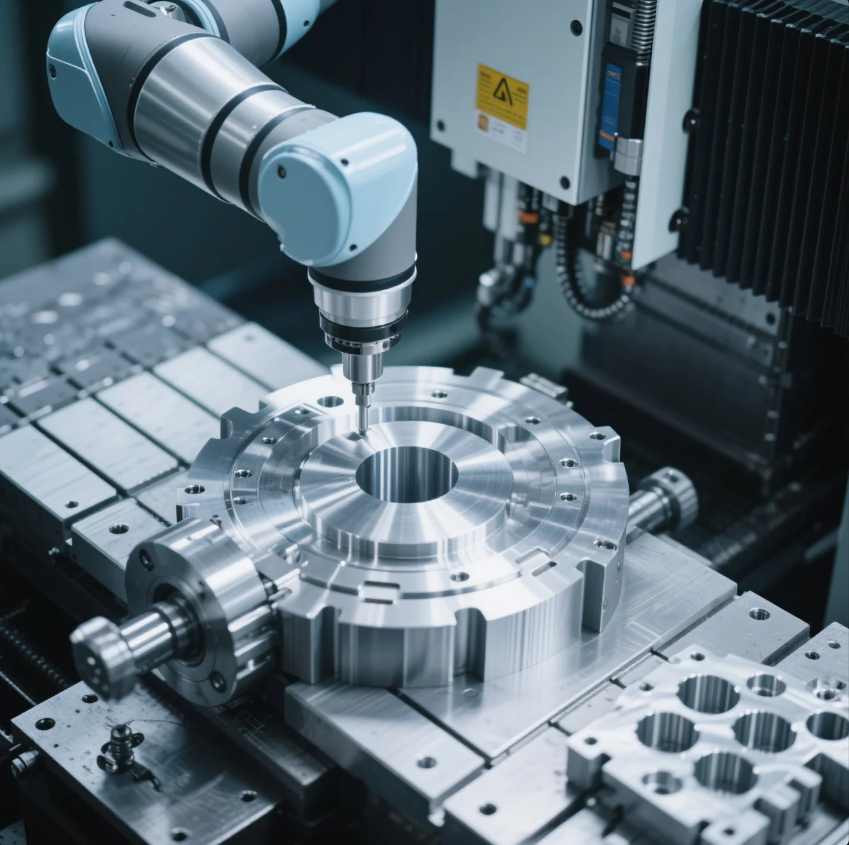

| Pattern Making | 2-40 hours | CNC wood/metal patterns | Dimensional inspection |

| Mold Preparation | 30-60 minutes | Sand mixer, rammer | Sand hardness test |

| Core Making | 15-45 minutes | Core boxes | Core strength test |

| Metal Melting | 1-4 hours | Induction furnace | Chemical analysis |

| Pouring | 2-10 minutes | Ladles | Temperature monitoring |

| Solidification | 15min-8hrs | Cooling area | Solidification time control |

| Shakeout | 10-30 minutes | Vibratory machine | Part integrity check |

| Finishing | 5-60 minutes | Grinders, shot blasters | Final dimensional verification |

Critical Process Parameters

| Factor | Optimal Range | Measurement Method |

|---|---|---|

| Sand Moisture | 3-5% | Loss-on-drying test |

| Pour Temp | +50-100°C above melting | Pyrometer |

| Mold Hardness | 70-90 (B scale) | Hardness tester |

| Cooling Rate | 10-50°C/min | Thermal camera |

Common Defects & Solutions

- Porosity: Increase venting, adjust pouring speed

- Misruns: Raise metal temperature, enlarge gates

- Shrinkage: Modify riser design, change alloy

What's the Difference in Die Casting Manufacturing?

Die casting delivers high-speed precision production through reusable metal molds.

Die casting parts are made by: 1) Heating metal ingots 2) Closing steel dies 3) Injecting molten metal under pressure 4) Cooling under pressure 5) Opening dies 6) Ejecting part 7) Trimming - achieving cycle times as fast as 30 seconds per part.

Die Casting Process Comparison

| Process Stage | Hot Chamber | Cold Chamber |

|---|---|---|

| Melting | Built-in furnace | Separate furnace |

| Injection Pressure | 7-15 MPa | 20-175 MPa |

| Cycle Time | 10-30 sec | 30-90 sec |

| Alloy Suitability | Zinc, magnesium | Aluminum, copper |

Tooling Components

| Die Element | Purpose | Material | Lifetime |

|---|---|---|---|

| Fixed Half | Stationary mold half | H13 steel | 100,000+ shots |

| Moving Half | Ejects finished part | H11 steel | 80,000+ shots |

| Cores | Forms internal features | H13 with coating | 50,000+ shots |

| Ejector Pins | Pushes part out | SKD61 steel | 60,000+ shots |

Process Optimization Techniques

- Slow shot phase: 0.2-0.5 m/s for air evacuation

- Fast shot phase: 2-5 m/s for complete filling

- Intensification pressure: 50-100 MPa during solidification

How Does Heat Treatment Improve Cast Parts?

Post-casting heat treatment enhances mechanical properties significantly.

The three main heat treatments are: 1) Stress relieving (200-650°C) 2) Annealing (fully softens) 3) Solution treatment (for alloys) - typically improving strength by 20-50% while reducing residual stresses that cause warpage.

Heat Treatment Specifications

| Process | Temperature Range | Holding Time | Cooling Method | Effect |

|---|---|---|---|---|

| Stress Relieving | 200-650°C | 1-4 hours | Air cool | Reduce stresses 80% |

| Annealing | 650-900°C | 2-8 hours | Furnace cool | Soften fully |

| Solution Treat | 450-550°C | 2-12 hours | Quench | Prep for aging |

| Precipitation | 100-200°C | 5-48 hours | Air cool | Increase strength |

Property Improvement Examples

| Material | Treatment | Tensile Strength Change | Hardness Change |

|---|---|---|---|

| A356 Aluminum | T6 heat treat | +150% (to 290MPa) | +80 BHN |

| Ductile Iron | Austempering | +100% (to 1200MPa) | +50% |

| C95400 Bronze | Solution+Age | +70% (to 760MPa) | +40 HRB |

Furnace Requirements

- Temperature uniformity: ±5°C

- Atmosphere control: Nitrogen/argon for sensitive alloys

- Quench rate control: 100-300°C/sec for aluminum

What Finishing Processes Do Cast Parts Need?

Surface finishing transforms raw castings into final products.

Common finishing operations include: 1) Grinding (removes gates) 2) Shot blasting (cleans surfaces) 3) Machining (achieves tight tolerances) 4) Coating (improves appearance/protection) - adding 5-25% to total part cost but enabling premium functionality.

Finishing Process Capabilities

| Method | Surface Improvement | Tolerance Achievable | Cost Factor |

|---|---|---|---|

| Grinding | Remove flash/gates | ±0.1mm | 1.2x |

| Sanding | Smooth surfaces | N/A | 1.05x |

| Machining | Critical dimensions | ±0.01mm | 1.3-2x |

| Anodizing | Corrosion resistance | N/A | 1.15x |

| Powder Coat | Decorative finish | N/A | 1.25x |

Defect Repair Techniques

| Defect Type | Repair Method | Success Rate | Cost Impact |

|---|---|---|---|

| Porosity | Welding/impregnation | 85-95% | +10-30% |

| Dimensional | Machining allowance | 100% | +5-15% |

| Surface | Grinding/polishing | 90% | +5-10% |

Quality Verification Steps

- Dye penetrant inspection for surface cracks

- X-ray for internal defects

- Coordinate measuring machine (CMM) for dimensions

Conclusion

Manufacturing casting parts requires methodical execution of pattern/mold preparation, controlled metal pouring, proper solidification management, and precise finishing - with each step tailored to the specific casting method and material properties.

TEMPLATE_END