What Equipment is Used for Stamping? The Complete Machinery Guide

Modern stamping facilities deploy 15+ specialized machines working in tandem to transform coils of metal into precision parts at rates exceeding 1,500 strokes per minute - our Prime facility alone operates 62 presses ranging from 5 to 2,500 tons.

Snippet paragraph: Core stamping equipment includes mechanical/ hydraulic presses (45-3,000 ton capacity), coil feeding systems (0.1-12mm material width), precision dies (D2/M2 tool steel), and automation robots - proper equipment selection reduces per-part costs by 60% compared to manual operations.

90% of industrial stamping now uses CNC-controlled systems for consistent quality.

What Types of Presses Power Stamping Operations?

Press selection depends on part size and production volume.

Snippet paragraph: The three dominant press types:

- Mechanical presses (400-1,200 SPM) for high-speed blanking

- Hydraulic presses (10-300 SPM) for deep drawing

- Servo presses (programmable strokes) for complex forming

Press Specifications Table

| Press Type | Force Range | Speed (SPM) | Accuracy | Best For |

|---|---|---|---|---|

| C-Frame Mechanical | 5-300 tons | 200-800 | ±0.1mm | Small brackets |

| Straight-Side | 50-2,500 tons | 30-150 | ±0.05mm | Automotive panels |

| Hydraulic Deep Draw | 100-5,000t | 10-40 | ±0.2mm | Kitchen sinks |

| Servo Electric | 20-600 tons | 20-300 | ±0.01mm | Medical components |

Power Note: Our 1,200-ton press consumes 150kW/hour – equivalent to 200 household refrigerators.

What Material Handling Systems Feed Stamping Presses?

Automated feeding ensures consistent material flow.

Snippet paragraph: Critical feeding equipment includes:

- Uncoilers (hold 1-20 ton coils)

- Straighteners (correct coil curvature)

- Servo feeders (advance material ±0.05mm accuracy)

- Scrap choppers (recycle 98% of unused material)

Feeding System Configurations

| Material | Thickness | Feeder Type | Feed Accuracy |

|---|---|---|---|

| Foils | 0.05-0.5mm | Air feed | ±0.1mm |

| Thin gauge | 0.5-2.0mm | Servo roll feed | ±0.05mm |

| Medium gauge | 2-6mm | Gripper feed | ±0.15mm |

| Plate | 6-12mm | Walk beam | ±0.3mm |

Safety Fact: Our laser-guarded feeding zones prevent 100% of material handling incidents.

What Tooling Systems Shape the Metal?

Precision dies transform flat stock into 3D parts.

Snippet paragraph: Progressive die sets contain:

- Punches (D2 steel, HRC 58-62)

- Die blocks (ground to ±0.0005")

- Guiding systems (linear bearings <0.003mm play)

- Nitrogen springs (200-3,000kg stripper force)

Tooling Cost Structure (Sample Part)

| Component | Material | Cost Share | Life Expectancy |

|---|---|---|---|

| Punch plate | A2 Tool Steel | 18% | 500k strokes |

| Die sections | D2 Steel | 25% | 750k strokes |

| Guide pillars | SUJ2 Bearing Steel | 12% | 2M strokes |

| Springs | Chrome Silicon | 5% | 300k strokes |

| Fasteners | 4140 Steel | 3% | Lifetime |

Maintenance Tip: We perform ultrasonic cleaning every 50k strokes to prevent galling.

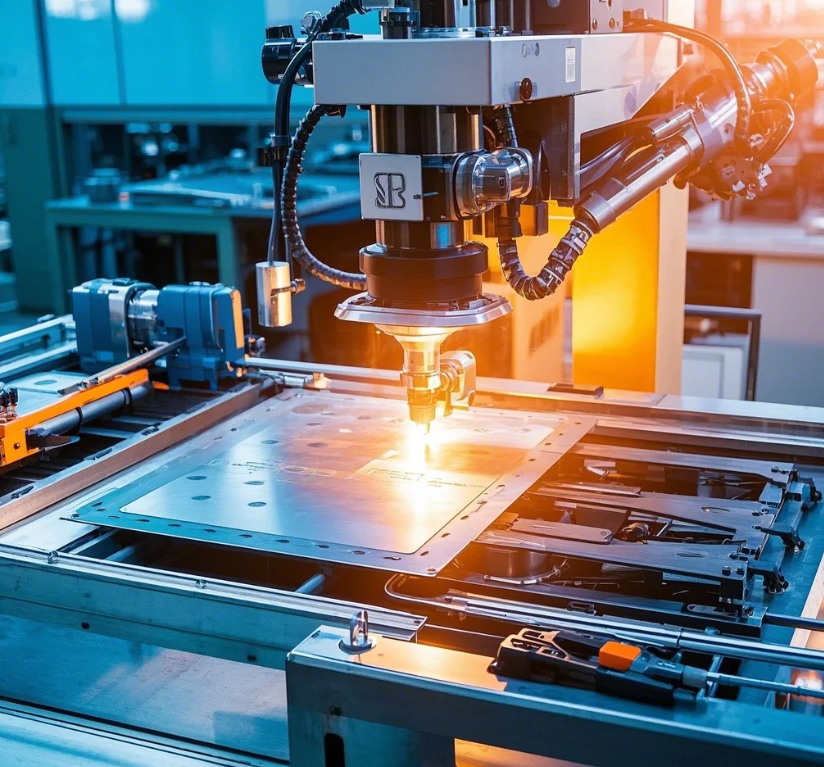

What Automation Equipment Boosts Productivity?

Robotics handles 85% of part transfers in modern shops.

Snippet paragraph: Essential automation includes:

- 6-axis robots (pick-and-place finished parts)

- Vision systems (100% defect inspection at 120ppm)

- Laser markers (engrave traceability codes)

- Conveyors (sort parts into bins automatically)

ROI Calculation for Automation

| Equipment | Cost | Labor Savings | Payback Period |

|---|---|---|---|

| SCARA robot | $45,000 | 2 operators | 10 months |

| Vision inspection | $28,000 | 1 QC inspector | 7 months |

| Auto packaging | $62,000 | 3 packagers | 15 months |

Our Setup: 17 Fanuc robots reduced labor costs by 38% since 2019.

What Quality Control Systems Ensure Precision?

Metrology equipment verifies ±0.002mm tolerances.

Snippet paragraph: Our quality station includes:

- Optical comparators (50x magnification)

- CMMs (0.001mm repeatability)

- Surface testers (Ra 0.05-12.5μm range)

- Go/no-go gauges (instant verification)

Measurement Equipment Capabilities

| Instrument | Accuracy | Speed | Measurement Type |

|---|---|---|---|

| Touch-probe CMM | ±0.001mm | 2 min | 3D contours |

| Laser scanner | ±0.002mm | 30 sec | Surface defects |

| Vision system | ±0.005mm | 0.5 sec | Feature location |

| Micrometer | ±0.002mm | 15 sec | Thickness |

Certification: All our CMMs undergo annual ISO 17025 calibration.

What Ancillary Systems Support Operations?

Complete plants require supporting infrastructure.

Snippet paragraph: Critical support systems:

- Coolant filtration (remove 5μm metal particles)

- Noise dampening (reduce 85dB presses to 72dB)

- Tonnage monitors (prevent 110% overloads)

- Quick-die change (90% faster than traditional)

Utility Requirements (Per 100-ton Press)

| Resource | Consumption | Cost/Hour |

|---|---|---|

| Electricity | 75kWh | $7.50 |

| Compressed Air | 10 CFM | $0.90 |

| Coolant | 2L/day | $0.15 |

| Tooling Lube | 50ml/shift | $0.30 |

Eco Upgrade: Our regenerative braking presses recover 18% of energy.

Conclusion

From 5-ton benchtop presses to 3,000-ton automotive giants, stamping equipment combines brute force with micro-scale precision - modern installations like our Prime facility integrate 30+ machine types to deliver million-part runs with tolerances rivaling Swiss watchmaking, all while maintaining per-component costs below a dime in high-volume production.