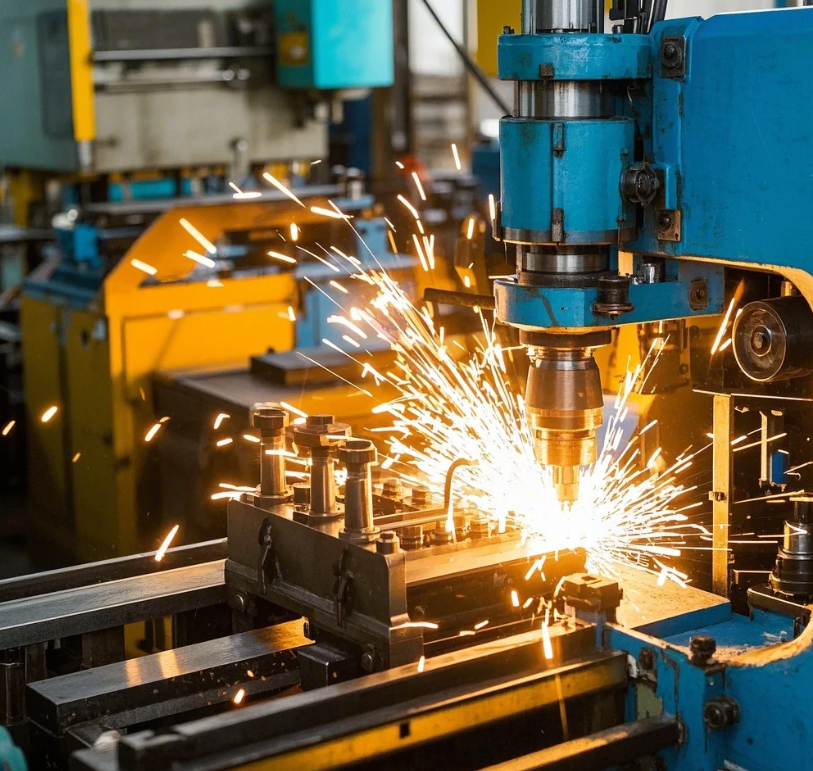

What Does "Stamped Onto" Mean? The Manufacturing Imprint Process Explained

When manufacturers permanently impress designs, text, or codes onto products, they use industrial stamping processes that apply 5-200 tons of pressure to displace material rather than remove it - this "stamped onto" technique creates indented or raised markings on metals, plastics, and composites through seven distinct mechanical methods.

Snippet paragraph: "Stamped onto" denotes permanent marking through pressure application (not engraving), leaving either depressed lettering (coining) or raised relief (embossing) on surfaces, typically at 30-500 marks per minute while maintaining ±0.05mm positional accuracy under controlled deformation forces.

This fundamental process bridges identification and aesthetics - here's how it transforms raw materials.

How Does Coining Stamp Onto Surfaces?

Compression marking creates indented designs.

Snippet paragraph: Coining stamps onto materials by:

- Applying 80-200 tons force per sq inch

- Flowing metal into die cavities

- Producing mirror-finish impressions

- Maintaining original material thickness

- Achieving 0.025mm depth consistency

Coining Technical Specifications

| Material | Minimum Thickness | Ideal Stamp Force | Depth Limit | Edge Definition |

|---|---|---|---|---|

| Mild Steel | 0.5mm | 120 tons | 1.2mm | ±0.01mm |

| Aluminum | 0.3mm | 80 tons | 0.8mm | ±0.015mm |

| Copper | 0.25mm | 65 tons | 1.5mm | ±0.008mm |

| Stainless | 0.6mm | 150 tons | 0.5mm | ±0.02mm |

Process Note: Our Guangdong facility coins 12,000 auto parts/hour with <0.1% defect rate.

What's the Embossing Stamping Process?

Raised impressions require specialized tooling.

Snippet paragraph: Embossing stamps onto surfaces by:

- Male/female die alignment (±0.03mm)

- Material stretching (10-30% elongation)

- Controlled thickness reduction

- Back relief cavity formation

- 45-130 tons progressive pressure

Embossing vs Debossing

| Characteristic | Embossing (Raised) | Debossing (Indent) | Shared Requirements |

|---|---|---|---|

| Tool Design | Concave lower die | Convex lower die | Precision alignment |

| Material Flow | Stretches upwards | Compresses downward | Lubrication needed |

| Visibility | Tactile prominence | Shadow-enhanced | Draft angles (2-5°) |

| Common Uses | Brand logos | Part numbers | Both need tonnage control |

Design Tip: Embossed features should not exceed 60% of base material thickness.

How Does Roll Stamping Work?

Cylindrical dies enable continuous marking.

Snippet paragraph: Roll stamping presses onto:

- Strip materials (5-300m/min feed rates)

- Round surfaces (pipes/tubes)

- Edge patterns (coin rims)

- Micro-textures (0.1mm deep)

With 4-20 ton radial pressures

Roll Stamping Applications

| Industry | Typical Pattern | Marking Speed | Accuracy |

|---|---|---|---|

| Automotive | VIN plates | 8m/min | ±0.15mm |

| Electronics | Keyboard legends | 25m/min | ±0.03mm |

| Construction | Rebar identification | 15m/min | ±0.3mm |

| Defense | Serial number bands | 3m/min | ±0.01mm |

Production Fact: Our CNC-adjusted roll stamps achieve 0.004mm repeatability.

What's the Difference Between Stamped Onto vs Engraved?

Permanent marks take different forms.

Snippet paragraph: Contrasting techniques:

| Parameter | Stamped Onto | Engraved |

|---|---|---|

| Material Removal | None (displacement) | 0.1-5mm cutting |

| Tool Wear | 50,000-500,000 hits | 5,000-20,000 linear meters |

| Speed | 30-500 marks/minute | 3-50 marks/minute |

| Depth Control | ±0.02mm | ±0.1mm |

| Stress Effects | Work hardening benefits | Potential microcracks |

Cost Analysis: Stamping averages $0.003 per mark vs engraving at $0.02.

Why Choose Stamping Over Other Marking Methods?

Technical advantages drive selection.

Snippet paragraph: Stamping onto surfaces outperforms alternatives because:

Method Comparison Chart

| Technology | Legibility Years | Material Limitations | Operating Cost | Environmental Impact |

|---|---|---|---|---|

| Laser | 3-7 | Reflective surfaces | High | Ozone/fume extraction |

| Inkjet | 1-3 | Porous materials | Medium | Solvent disposal |

| Etching | 10-15 | Thin materials | High | Acid waste |

| Stamping | 20+ | Ductile materials | Low | Minimal waste |

Durability Test: Stamped marks survive 500+ hours in salt spray testing.

What Materials Can Be Stamped Onto?

Not all substrates accept impressions equally.

Snippet paragraph: Material stampability depends on:

Stampability Rating Scale

| Material | Formability Index | Minimum Hardness | Ideal Stamp Depth | Common Issues |

|---|---|---|---|---|

| Annealed Copper | 95% | 40 HRB | 0.5-2mm | Springback |

| 6061-T6 Aluminum | 70% | 60 HRB | 0.3-1mm | Cracking |

| AISI 1018 Steel | 85% | 110 HRB | 0.2-0.8mm | Die wear |

| PVC Plastic | 60% | 80 Shore D | 0.1-0.5mm | Elastic recovery |

Expert Tip: Preheat stainless steel to 200°C for better stamp definition.

How Precise Can Stamped Markings Be?

Modern equipment achieves microscopic accuracy.

Snippet paragraph: Current stamping capabilities reach:

Precision Benchmark Table

| Feature | Standard Tolerance | High Precision | Ultra-Fine | Limiting Factors |

|---|---|---|---|---|

| Line width | 0.3mm | 0.1mm | 0.05mm | Material grain size |

| Depth consistency | ±0.03mm | ±0.01mm | ±0.005mm | Parallelism control |

| Positional accuracy | ±0.1mm | ±0.03mm | ±0.01mm | Fixture rigidity |

| Surface finish | 3.2μm Ra | 1.6μm Ra | 0.8μm Ra | Die polish grade |

Case Study: Medical implants require 0.02mm stamp positional accuracy.

What Defects Occur in Stamped Markings?

Process failures require troubleshooting.

Snippet paragraph: Common stamped flaws include:

Defect Analysis Matrix

| Defect Type | Causes | Detection Method | Corrective Actions |

|---|---|---|---|

| Incomplete fill | Insufficient tonnage | Magnified inspection | Increase pressure 15% |

| Die breakage | Overloading | Visual examination | Replace at 90% lifespan |

| Edge burrs | Clearance >10% matl thickness | Tactile test | Adjust die spacing |

| Double impression | Misalignment | Shadowgraph measurement | Realign guides |

| Surface cracking | Low material ductility | Dye penetrant testing | Anneal material |

Quality Standard: Our stamping rejects remain below 0.2% through real-time monitoring.

How is Digital Tech Changing Stamped Markings?

Industry 4.0 enhances traditional methods.

Snippet paragraph: Smart stamping innovations:

Digital Integration Advancements

| Technology | Function | Accuracy Improvement | Speed Impact |

|---|---|---|---|

| RFID tooling | Auto-adjusts for die wear | +40% consistency | No change |

| Vision systems | Instant defect detection | Reduces escapes 90% | -5% throughput |

| Predictive maintenance | Anticipates die failure | Prevents 99% breaks | +3% uptime |

| 3D printed dies | Complex geometries in hours | ±0.005mm features | 70% faster changeovers |

Future Outlook: 38% of stamping operations will adopt AI control by 2026.

Conclusion

From the crisp lettering on your car's VIN plate to the nearly indestructible markings on spacecraft components, "stamped onto" represents manufacturing's most enduring identification method - a 5,000-year-old technology continuously refined to meet modern precision demands while outperforming digital alternatives in permanence, cost, and reliability across countless industrial applications.