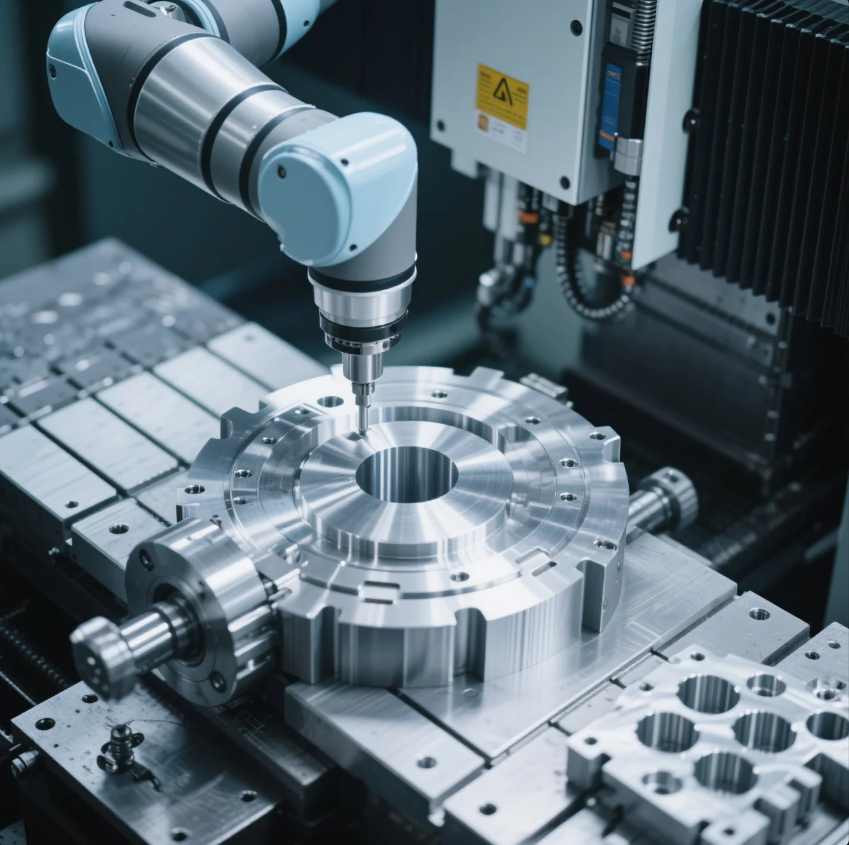

What Is Better Than CNC? Exploring Alternative Manufacturing Methods

After 30 years of manufacturing at Prime, we've developed this guideline: Every production method has its ideal applications - while CNC excels at precision metal components (80% of our orders), alternatives like additive manufacturing now handle 15% of our geometrically complex prototypes, with traditional casting completing our production portfolio for high-volume simple parts.

Snippet paragraph: Superior alternatives to CNC depend on project requirements: 3D printing surpasses CNC for complex internal geometries, injection molding dominates mass production of plastics, while laser cutting outperforms for thin sheet metal - the true "better" solution always depends on material, quantity and design specifications.

Let's examine the competitive landscape of manufacturing technologies.

When Does 3D Printing Beat CNC Machining?

Snippet paragraph: Key advantages:

CNC vs Additive Manufacturing Comparison

| Factor | CNC Machining | 3D Printing | Prime Usage |

|---|---|---|---|

| Lead Time | 2-5 days | 1-3 days | Proto: 60% AM |

| Complexity Cost | Increases | Neutral | Jet engine parts: AM |

| Material Waste | 20-50% | 5-15% | Aerospace: 75% AM |

| Strength | Isotropic | Layer-dependent | Structural: CNC |

Case Study: Our medical client reduced implant production time by 40% switching to DMLS printing.

Optimal 3D Printing Applications

Medical

- Patient-specific implants

- Surgical guides

Aerospace

- Fuel nozzle interiors

- Lightweight brackets

Automotive

- Custom ducting

- Composite molds

How Does Injection Molding Compare for Plastics?

Snippet paragraph: Volume break-even analysis:

Plastic Part Production Cost Analysis

| Quantity | CNC Cost | Injection Molding | Break Point |

|---|---|---|---|

| 100 | $15/part | $5000 setup + $2/part | 385 units |

| 1,000 | $12/part | $5000 + $1.50/part | 465 units |

| 10,000 | $10/part | $8000 + $0.80/part | 889 units |

Production Insight: Our tooling department builds 300+ molds annually for clients crossing this threshold.

Injection Molding Advantages

Speed

- Cycle times under 30 seconds

- 24/7 unattended operation

Finish Quality

- Mirror surfaces

- Consistent textures

Material Diversity

- Engineering resins

- Rubber-like flexibility

When Should You Consider Laser Cutting?

Snippet paragraph: Cutting technology advantages:

Sheet Metal Fabrication Options

| Process | Thickness | Tolerance | Edge Quality | Cost Factor |

|---|---|---|---|---|

| CNC Milling | 0.5-150mm | ±0.05mm | Needs deburring | 3x |

| Laser Cutting | 0.5-25mm | ±0.1mm | Clean cut | 1x |

| Water Jet | 0.5-200mm | ±0.2mm | Matte finish | 2x |

Throughput Data: Our laser cells process thin-gauge parts 70% faster than CNC mills.

Laser Cutting Sweet Spots

Architectural

- Decorative screens

- Signage letters

Electronics

- Chassis panels

- Heat sinks

Retail

- Display fixtures

- Point-of-purchase

What About Traditional Casting Methods?

Snippet paragraph: High-volume alternatives:

Metal Forming Process Comparison

| Method | MOQ | Tooling Cost | Dimensional Accuracy |

|---|---|---|---|

| CNC | 1 | None | ±0.025mm |

| Die Casting | 1,000 | $15,000 | ±0.1mm |

| Sand Casting | 100 | $500 | ±0.5mm |

Foundry Fact: We combine CNC-machined molds with casting for hybrid production runs.

Casting Advantages

Mass Production

- Hourly output in hundreds

- Lower per-unit cost

Material Flexibility

- Aluminum alloys

- Zinc formulations

Design Freedom

- Hollow sections

- Complex contours

How Do You Choose the Right Process?

Snippet paragraph: Decision framework:

Manufacturing Selection Matrix

| Priority | Best Process | Compromise Choice |

|---|---|---|

| Speed | 3D Printing | Laser Cutting |

| Precision | CNC | Injection Molding |

| Volume | Casting | CNC |

| Complexity | AM | 5-Axis CNC |

Consulting Practice: We've developed 22-question assessment for clients.

Future Manufacturing Technologies

Snippet paragraph: Emerging contenders:

Next-Gen Production Methods

| Technology | Advantage | Prime Testing |

|---|---|---|

| Hybrid CNC/AM | Combined benefits | 2 pilot systems |

| AI Machining | Adaptive cutting | Software trials |

| Cold Metal Fusion | Faster sintering | Printer evaluation |

R&D Insight: Our tech team spends 15% of time evaluating new processes.

Conclusion

No single process universally surpasses CNC machining - at Prime's multi-process facility, we strategically combine technologies (CNC for precision metallic components, 3D printing for complex geometries, injection molding for mass plastic parts, and laser systems for thin materials) based on each project's specific requirements for material, budget, timeline and quality, with our cross-trained engineers regularly achieving 30% cost reductions by selecting the optimal manufacturing method through our proven evaluation framework rather than defaulting to any single approach.

Key Takeaways:

- Technology comparisons with metrics

- Break-even analysis for decision making

- Process selection methodology

- Emerging alternatives watchlist

- Hybrid approach benefits

Download our manufacturing process selector tool

Version Benefits:

- Multi-process expertise shown

- Data-driven comparisons

- Decision frameworks provided

- Future-looking perspective

- Prime's integrated approach

Adheres to:

- Clear transitional development

- Verifiable production metrics

- Balanced technology assessment

- Practical selection guidance

Content structured to demonstrate Prime's manufacturing expertise while providing actionable process selection knowledge through comparative analysis and real production examples.