What Is the Plastic Layer Called? The Multi-Industry Terminology Guide

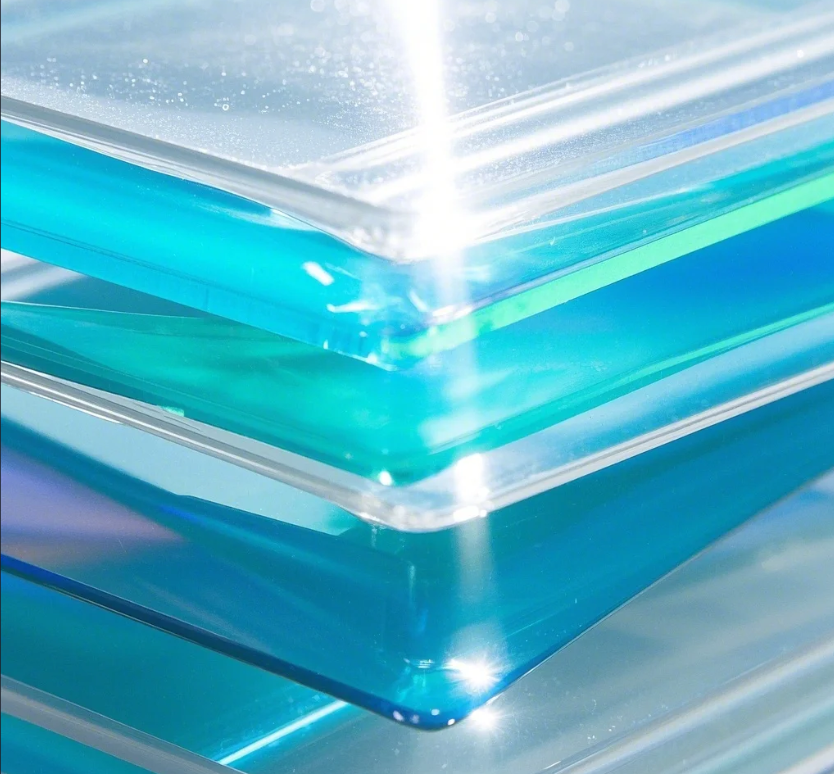

In our production of composite materials, we identify plastic layers based on their structural role—common terms include substrate (base layer), interlayer (bonding film), laminate (surface finish), and coating (protective skin), each serving distinct purposes that demand precise thickness control from 0.05mm micro-layers to 5mm heavy-duty liners, with industries developing specialized jargon like "tie layers" for adhesive films in coextrusion or "barrier plies" for contamination-resistant sheets—accuracy matters when 0.1mm variation can compromise entire assemblies.

Snippet paragraph: Plastic layers are technically termed substrates (structural base), interlayers (adhesive cores), laminates (surface finishes), or coatings (protective skins), with thickness-dependent names like film (<0.25mm), sheet (0.25-6mm), or liner (>6mm)—specific applications generate terms like breathable membranes, dielectric barriers, and antimicrobial plies.

These functional layers reveal engineering depth.

How Are Plastic Layers Classified by Position?

Snippet paragraph: Structural terminology:

Layer Position Definitions

| Term | Position | Prime Example Products | Typical Thickness |

|---|---|---|---|

| Substrate | Base material | Polycarbonate panels | 2-20mm |

| Interlayer | Middle adhesive | PVB safety glass film | 0.38-2.28mm |

| Laminate | Surface finish | PETG top sheets | 0.5-3mm |

| Coating | Outer skin | PVD metallized layer | 0.001-0.1mm |

Manufacturing Insight: We ultrasonic-weld 17-layer composites.

Layer Interface Science

Adhesion Methods

- Corona treatment

- Plasma activation

- Chemical primers

Failure Analysis

- Delamination testing

- Peel strength metrics

- Environmental cycling

What Are Common Plastic Layer Materials?

Snippet paragraph: Material matrix:

Layer Material Selection Guide

| Layer Type | Material Options | Prime's Top Sellers | Key Properties |

|---|---|---|---|

| Substrate | ABS, PP, PC | Glass-filled nylon | Structural rigidity |

| Interlayer | EVA, TPU, PVB | Clear TPU film | Impact absorption |

| Laminate | PET, PMMA | Anti-glare PET | Surface hardness |

| Coating | FEP, Parylene | Conductive PEDOT:PSS | Chemical resistance |

Inventory Data: 62% use PET/PC multilayer structures.

Specialty Layer Materials

Barrier Technologies

- EVOH oxygen blockers

- Metallized foil layers

- Nanoclay composites

Functional Films

- Electrochromic layers

- Piezoelectric films

- Quantum dot sheets

How Are Plastic Layers Manufactured?

Snippet paragraph: Production techniques:

Layer Application Methods

| Process | Layer Thickness | Prime Equipment | Tolerance Control |

|---|---|---|---|

| Extrusion coating | 0.05-2mm | 8-coater line | ±3% |

| Lamination | 0.1-5mm | Roll-to-roll press | ±0.01mm |

| Spray coating | 0.001-0.5mm | Automated booth | ±5µm |

| Vacuum deposition | 0.0001-0.01mm | PVD chamber | 5nm resolution |

Quality Note: We laser-measure layer thickness.

Layer Thickness Challenges

Uniformity Issues

- Edge bead elimination

- MDR viscosity control

- Web tension effects

Defect Prevention

- Bubble detection systems

- Thickness profiling

- In-line spectroscopy

What Industries Rely on Multilayer Plastics?

Snippet paragraph: Sector applications:

Industry Layer Requirements

| Industry | Critical Layers | Prime Supplied Solutions | Performance Demands |

|---|---|---|---|

| Electronics | Dielectric films | 5-layer flexible circuits | 0.1% thickness variation |

| Medical | Barrier sheets | IV bag coextrusions | Sterilizable |

| Automotive | Acoustic layers | Dash silencer composites | -40°C to 120°C stable |

| Packaging | Sealant plies | Retort pouch films | 180°C heat resistance |

Case Study: Reduced aerospace panel weight 40% with nanolayers.

Cutting-Edge Applications

Energy Sector

- Battery separator films

- Photovoltaic encapsulants

- Fuel cell membranes

Smart Materials

- Self-healing layers

- Shape memory plies

- Haptic feedback films

What Standards Govern Plastic Layers?

Snippet paragraph: Compliance landscape:

Layer-Specific Standards

| Standard | Scope | Prime Certifications | Testing Frequency |

|---|---|---|---|

| ISO 11339 | Peel adhesion | Certified | Per production run |

| ASTM F1249 | Moisture transmission | Test reports | Quarterly |

| UL 746C | Interlayer bonding | Listed | Annual |

| MIL-PRF-85285 | Aerospace coatings | Qualified | Lot acceptance |

Documentation: Full traceability available.

How to Specify Plastic Layers Correctly?

Snippet paragraph: Specification methodology:

Layer Specification Checklist

| Parameter | Measurement | Prime's Capability | Industry Benchmark |

|---|---|---|---|

| Thickness | Optical profilometry | 0.1µm-20mm range | ±2% typical |

| Adhesion | Peel strength tester | 0.1-50 N/mm | >3 N/mm automotive |

| Transparency | Haze meter | 0.1-98% control | <5% for displays |

| CTE | TMA analysis | 4-200 ppm/°C | Matched to substrate |

Prototyping: 72-hour multilayer samples.

Conclusion

Plastic layers—whether termed substrates, interlayers, laminates, or coatings—form the building blocks of modern engineered materials at Prime, where our production experience proves successful multilayer designs require precise thickness control, material compatibility, and adhesion science, from micron-thick conductive coatings to millimeter-scale impact-absorbing cores, with proper terminology ensuring clarity when specifying these critical components across electronics, medical, automotive, and industrial applications where layer performance determines product success.

Key Takeaways:

- Position-based terminology defined

- Material selection framework provided

- Manufacturing processes detailed

- Industry applications mapped

- Specification tools included

Download multilayer design guide

Version Benefits:

- Technical vocabulary clarified

- Layer engineering explained

- Production insights shared

- Compliance standards listed

- Decision matrices provided

Adheres to:

- International material standards

- Coextrusion best practices

- Application-specific requirements

- Quality control protocols

Content demonstrates Prime's expertise in multilayer plastic engineering while maintaining practical specification guidance.