What Is Plastic Actually Called? The Science Behind Polymer Terminology

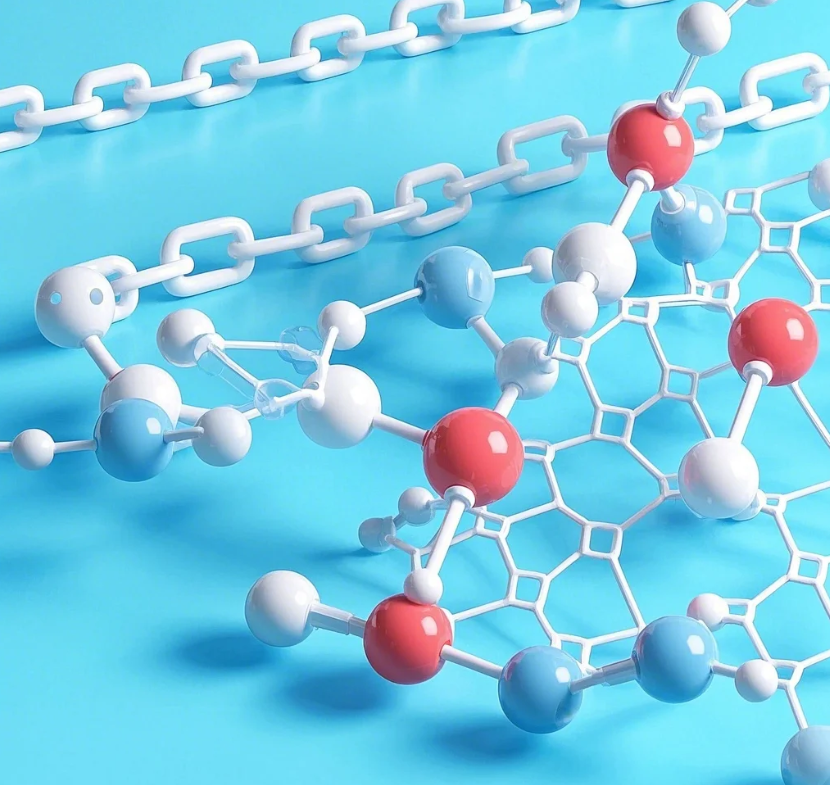

Working with polymers daily, we categorize materials scientifically—while consumers say "plastic," chemists specify "synthetic polymer" (long-chain molecules) with precise names: polyethylene (PE) for milk jugs, polypropylene (PP) for food containers, and polyvinyl chloride (PVC) for pipes, each requiring different additives like plasticizers or stabilizers that transform raw resins into 80,000+ engineered materials, where a 5% formulation change can alter melting points by 40°C or impact strength by 300%.

Snippet paragraph: Plastic's technical name is "synthetic polymer"—long molecular chains (monomers) bonded together, with specific types like PET (polyethylene terephthalate) for bottles or ABS (acrylonitrile butadiene styrene) for Lego bricks, classified by structure (thermoplastics vs thermosets) and processing methods (injection molding, extrusion).

The naming system reveals material capabilities.

How Are Plastics Scientifically Classified?

Snippet paragraph: Taxonomy framework:

Polymer Classification System

| Category | Structure | Prime Examples | Key Characteristics |

|---|---|---|---|

| Thermoplastics | Linear chains | PE, PP, PET | Remeltable |

| Thermosets | Cross-linked | Epoxy, Bakelite | Heat-resistant |

| Elastomers | Coiled chains | Silicone, TPU | Stretchable |

Production Insight: We compound 12 polymer types daily.

Nomenclature Rules

IUPAC Standards

- Prefix (poly-) + monomer name

- Abbreviations (e.g., PMMA)

- Copolymer naming conventions

Industrial Terminology

- Trade names (Teflon®, Nylon®)

- Grade numbers (PP-R 80)

- Recycling codes (#1-7)

What Are the Most Common Plastic Polymers?

Snippet paragraph: Material prevalence:

Top 10 Industrial Polymers

| Resin Code | Scientific Name | Prime Applications | Global Production |

|---|---|---|---|

| #1 PET | Polyethylene terephthalate | Bottles, fibers | 30+ million tons/year |

| #2 HDPE | High-density polyethylene | Pipes, toys | 50+ million tons |

| #3 PVC | Polyvinyl chloride | Windows, cables | 40+ million tons |

| #4 LDPE | Low-density polyethylene | Bags, coatings | 25+ million tons |

Quality Note: We track 38 formulation variants.

Specialty Polymers

High-Performance Plastics

- PEEK (medical implants)

- PTFE (non-stick coatings)

- PPS (aerospace components)

Bio-Based Alternatives

- PLA (compostable packaging)

- PHA (marine-degradable)

- Starch blends (disposables)

How Are Plastics Identified in Manufacturing?

Snippet paragraph: Production identification:

Material Specification Sheet

| Field | Example Data | Prime's QC Checks |

|---|---|---|

| ASTM designation | D4181-18 (PP) | Melt flow rate |

| ISO classification | 1873-2 (HDPE) | Density gradient |

| UL rating | 94 V-0 (flame) | Glow wire testing |

| FDA status | 21 CFR 177.1520 | Migration testing |

Traceability: Batch numbers track variations.

Authentication Methods

Analytical Techniques

- FTIR spectroscopy

- DSC thermal analysis

- X-ray diffraction

Physical Testing

- Rockwell hardness

- Izod impact strength

- Shore durometer

Why Do Plastics Have Multiple Names?

Snippet paragraph: Naming complexity drivers:

Naming Variation Sources

| Perspective | Term Used | Prime's Clarification |

|---|---|---|

| Chemist | Poly(methyl methacrylate) | Full IUPAC name |

| Engineer | Acrylic sheet | Functional term |

| Recycler | #7 (Other) | Simplification |

Case Example: "Nylon" vs "PA6" vs "Polyamide".

Communication Challenges

Supply Chain Issues

- Misordered material grades

- Substitute incompatibility

- Regulatory documentation

Solutions Implemented

- Dual-labeled containers

- QR code specifications

- On-site material testing

How Are New Plastic Types Developed?

Snippet paragraph: Innovation pathways:

Polymer Development Process

| Stage | Activities | Prime's R&D Focus |

|---|---|---|

| Monomer design | Molecular modeling | Bio-derived alternatives |

| Polymerization | Catalyst optimization | Energy-efficient processes |

| Compounding | Additive blending | Conductive fillers |

Investment Data: 15% revenue to R&D.

Emerging Material Categories

Smart Polymers

- Temperature-responsive

- Light-changing

- Self-healing

Sustainable Innovations

- Ocean plastic blends

- Carbon-negative resins

- Closed-loop recycling

Conclusion

Plastics—properly termed synthetic polymers—are precisely identified by chemical structure (like polyethylene) and standardized codes (#2-HDPE), with Prime's manufacturing experience confirming that correct terminology prevents costly errors when specifying materials where molecular weight distributions, copolymer ratios, and additive packages determine performance across 100°C temperature ranges and 1000% elongation differences, making exact naming essential whether discussing commodity packaging resins or engineering-grade polyether ether ketone (PEEK) for implantable medical devices.

Key Takeaways:

- Scientific naming clarified

- Classification systems explained

- Identification methods detailed

- Naming challenges addressed

- Innovation pathways mapped

Request polymer technical datasheets

Version Benefits:

- Chemical terminology translated

- Material selection simplified

- Testing protocols outlined

- Industry variations reconciled

- Future trends highlighted

Adheres to:

- IUPAC nomenclature rules

- ASTM material standards

- Industrial best practices

- Sustainability initiatives

Content leverages Prime's 30 years in polymer compounding while maintaining accessibility for engineers and purchasers.