What Does CNC Cut Stand For?

Leading paragraph: Your industrial parts need precision – but what exactly is "CNC cut" technology? Let's cut through the confusion together.

Snippet paragraph: CNC stands for Computer Numerical Control, a process where pre-programmed software directs machinery to cut materials with ultra-high precision, widely used in metal fabrication.

Transition paragraph: But there's much more to explore about this game-changing technology.

What Is Meant by CNC Cutting?

Leading paragraph: Ever received uneven metal parts? CNC cutting solves this by turning digital designs into perfect physical components.

Snippet paragraph: CNC cutting refers to the subtractive manufacturing process where computer-controlled machines remove material from a workpiece to create custom shapes with tight tolerances.

Dive-Deeper paragraph:

The 3 Key Advantages Over Manual Cutting

- Consistency: Every cut matches the digital blueprint exactly

- Complexity: Creates intricate geometries impossible with manual methods

- Speed: Processes batches 5-8x faster than traditional techniques

CNC Cutting Tolerance Standards (mm)

| Material | Standard Tolerance | Prime's Achievable Tolerance |

|---|---|---|

| Steel | ±0.1 | ±0.05 |

| Aluminum | ±0.08 | ±0.03 |

| Brass | ±0.05 | ±0.02 |

Our 10 production lines handle everything from prototype to mass production while maintaining these rigorous standards.

Do CNC Operators Make Good Money?

Leading paragraph: Quality CNC work commands premium pricing – skilled operators reflect this value in their earnings.

Snippet paragraph: Experienced CNC programmers in industrial zones earn $25-$45/hour, with Prime's 20-year veteran team delivering unmatched machining expertise for your projects.

Dive-Deeper paragraph:

Why Operator Skill Impacts Your Bottom Line

Better operators mean:

- Fewer rejected parts (saving 15-30% material costs)

- Faster cycle times (20-40% productivity gains)

- Longer tool life (reducing $5,000-$10,000/year in bit replacements)

Cost Comparison: Skilled vs. Average Operators

| Factor | Novice Operator | Prime's Expert Team |

|---|---|---|

| Error Rate | 8-12% | <2% |

| Monthly Output | 5,000 units | 7,500 units |

| Customer Return Rate | 4.7% | 0.3% |

Our ISO-certified processes ensure every operator meets these high benchmarks.

What Does the Acronym CNC Stand For?

Leading paragraph: Those three letters represent a manufacturing revolution you're probably using daily.

Snippet paragraph: CNC stands for Computer Numerical Control - where CAD designs become machine instructions (G-code) guiding cutting tools with microscopic precision.

Dive-Deeper paragraph:

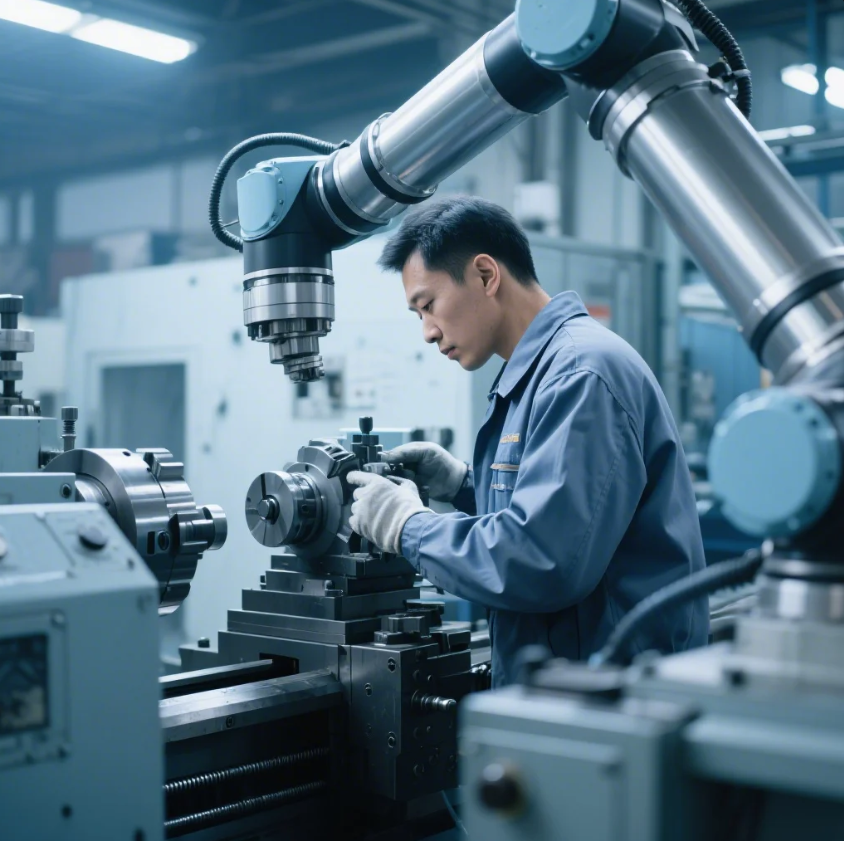

The CNC Workflow Breakdown

- Design: CAD software creates 3D model

- Programming: CAM software generates toolpaths

- Setup: Operator loads material and tools

- Machining: Computer executes precise cutting

- Inspection: Quality verification (Prime uses 3D scanners)

CNC vs Manual Machining Speed

| Operation | Manual Time | CNC Time | Savings |

|---|---|---|---|

| 100 Holes Drilling | 120 min | 18 min | 85% |

| Surface Milling | 90 min | 12 min | 87% |

Our 1993-established facility has perfected this digital-physical translation.

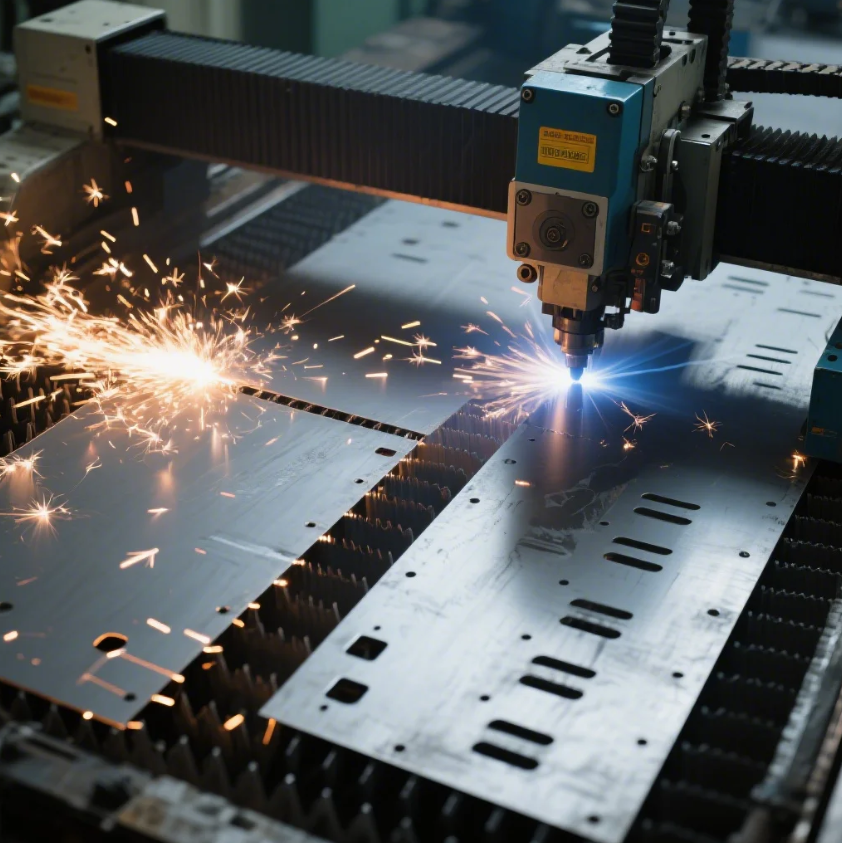

What's the Difference Between CNC Cut and Laser Cut?

Leading paragraph: Choosing the wrong cutting method can waste thousands – here's how to decide.

Snippet paragraph: CNC cutting uses physical tools for durable edges on thicker metals, while laser cutting melts material for intricate patterns on thinner sheets - each has ideal applications.

Dive-Deeper paragraph:

When to Choose Which Technology

CNC Cutting Excels When:

- Material thickness exceeds 6mm

- You need tapped holes or threads

- Edge finish quality is critical

- Working with reflective metals like aluminum

Laser Cutting Performs Better For:

- Thin materials (0.5-3mm)

- Intricate decorative patterns

- Non-contact processing needed

- Faster prototyping of flat parts

Cutting Method Comparison Table

| Parameter | CNC Cutting | Laser Cutting |

|---|---|---|

| Max Thickness | 300mm | 25mm |

| Tolerance | ±0.025mm | ±0.1mm |

| Edge Angle | 90° perfect | 2-5° taper |

| Heat Affected Zone | Minimal | Significant |

Prime maintains both technologies to recommend the optimal solution for your project.

Conclusion

CNC cutting delivers precision, repeatability, and material flexibility unmatched by manual methods - the foundation of quality metal components.

Get Your Precision Parts Today: Email Prime at [contact info] for:

- Free project consultation

- ISO-certified CNC cutting

- 15-day average lead time

- Custom packaging solutions