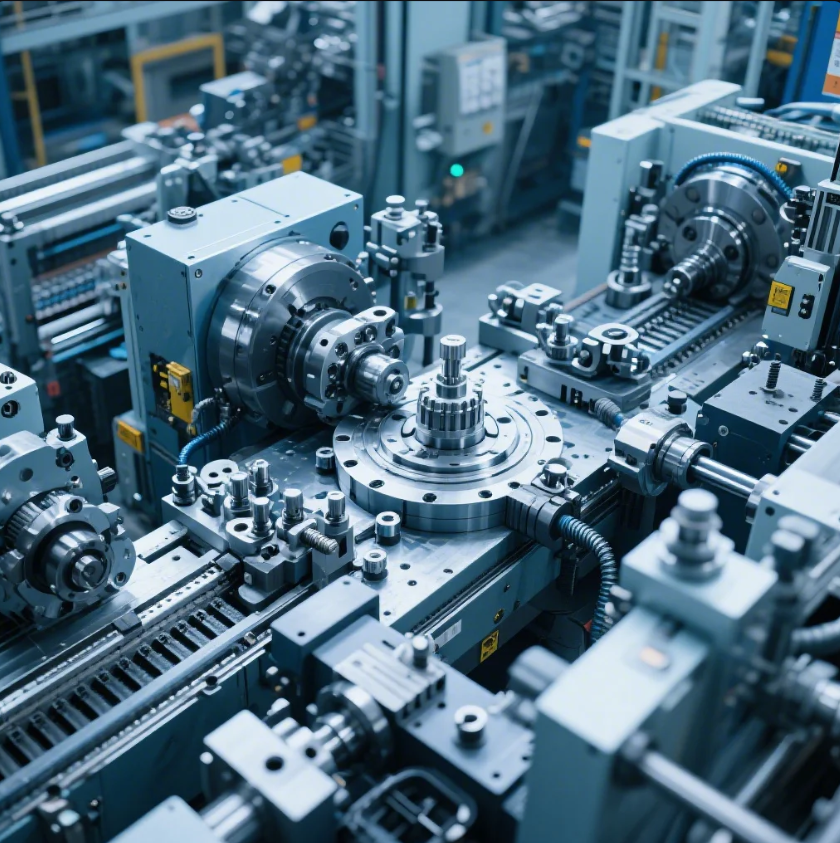

What Is Better Than CNC? Understanding Modern Manufacturing Alternatives

Leading paragraph: Facing production limitations with CNC? Discover advanced technologies that outperform traditional machining for specific applications.

Snippet paragraph: While CNC remains vital for precision metalwork, emerging technologies like 3D printing (SLS/DMLS), laser cutting, and EDM often provide better solutions for complex geometries and specialized materials.

Transition paragraph: Let's examine when alternative methods deliver superior results.

What Is Alternative for CNC?

Leading paragraph: When conventional machining falls short, these technologies fill critical manufacturing gaps.

Snippet paragraph: Prime offers seven alternatives to standard CNC: laser cutting (<0.1mm thickness), waterjet (any material), EDM (hardened metals), SLS (complex internals), ultrasonic (brittle materials), additive (lightweighting), and hybrid systems combining multiple advantages.

Dive-Deeper paragraph:

Technology Selection Guide

Decision Factors for Alternative Processes

| Parameter | CNC Limitation | Better Alternative | Advantage |

|---|---|---|---|

| Material Hardness >55HRC | Tool wear | EDM | No contact cutting |

| Wall Thickness <0.5mm | Chatter | Laser | No mechanical force |

| Internal Channels | Limited access | SLS 3D Printing | No toolpath restrictions |

| Composite Layers | Delamination | Ultrasonic | Vibration bonding |

| Part Consolidation | Assembly needed | DMLS | Single-piece construction |

Prime's Equipment Matrix

For Prototyping:

- SLS Nylon: $8/cm³

- DMLS Metal: $15/cm³

- Micro CNC: $45/hour

For Production:

- 5-Axis CNC: $85/hour

- Waterjet: $120/hour

- Laser Tube Cutting: $65/hour

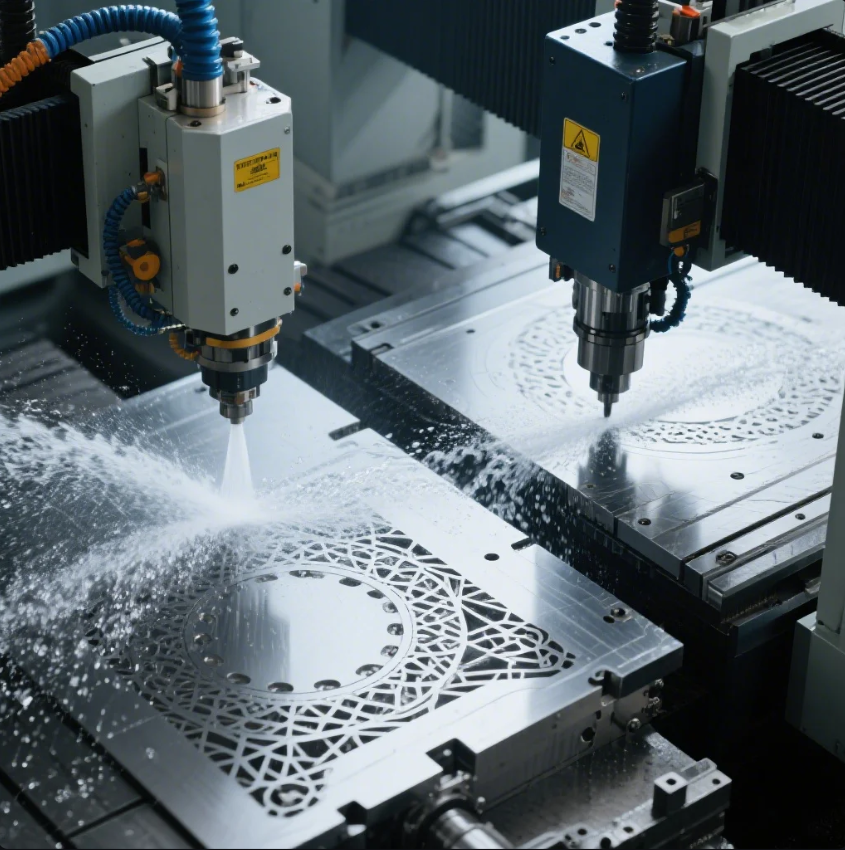

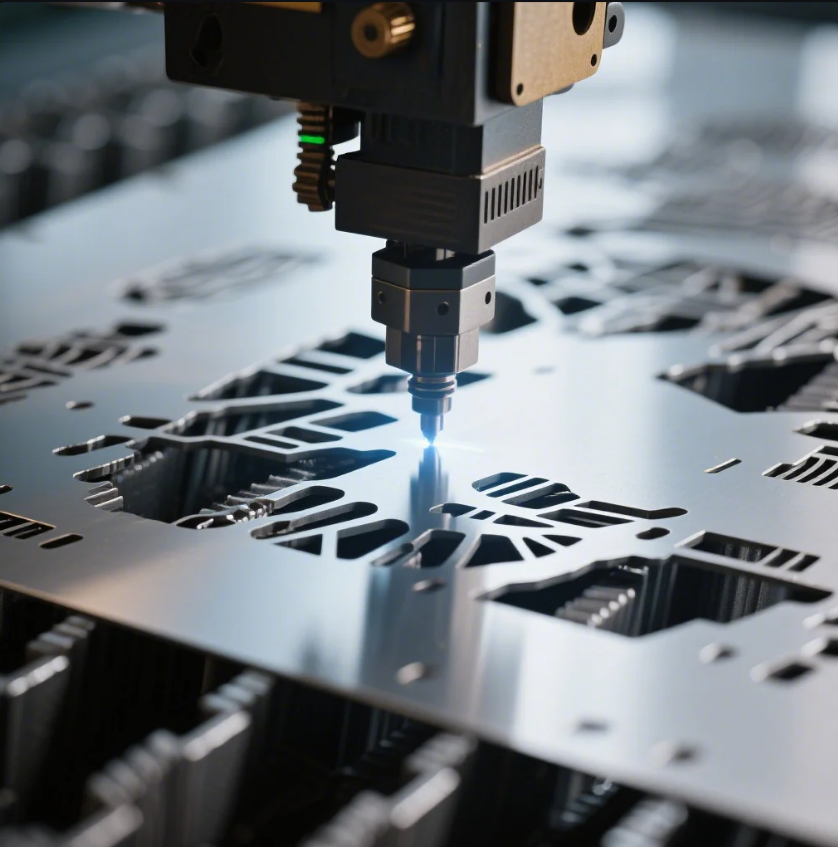

Is a CNC or Laser Better?

Leading paragraph: The cutting technology debate depends on your material, precision, and budget needs.

Snippet paragraph: Lasers outperform CNC for thin materials (<6mm) with ±0.05mm precision and 10x faster cutting, while CNC maintains superiority for thick parts (>25mm) requiring dimensional tolerances below 0.01mm.

Dive-Deeper paragraph:

Head-to-Head Comparison

Cut Quality Analysis

| Feature | CNC Router | Fiber Laser |

|---|---|---|

| Kerf Width | 1-3mm | 0.1-0.3mm |

| Heat Affected Zone | Minimal | 0.2-0.8mm |

| Edge Finish | Ra 3.2μm | Ra 1.6μm |

| Angular Accuracy | ±0.1° | ±0.05° |

When to Choose Each:

Laser Wins When:

- Cutting thin stainless (0.5-4mm)

- Complex 2D profiles

- No secondary finishing desired

CNC Wins When:

- Aluminum >8mm thickness

- 3D contour machining

- Structural component needs

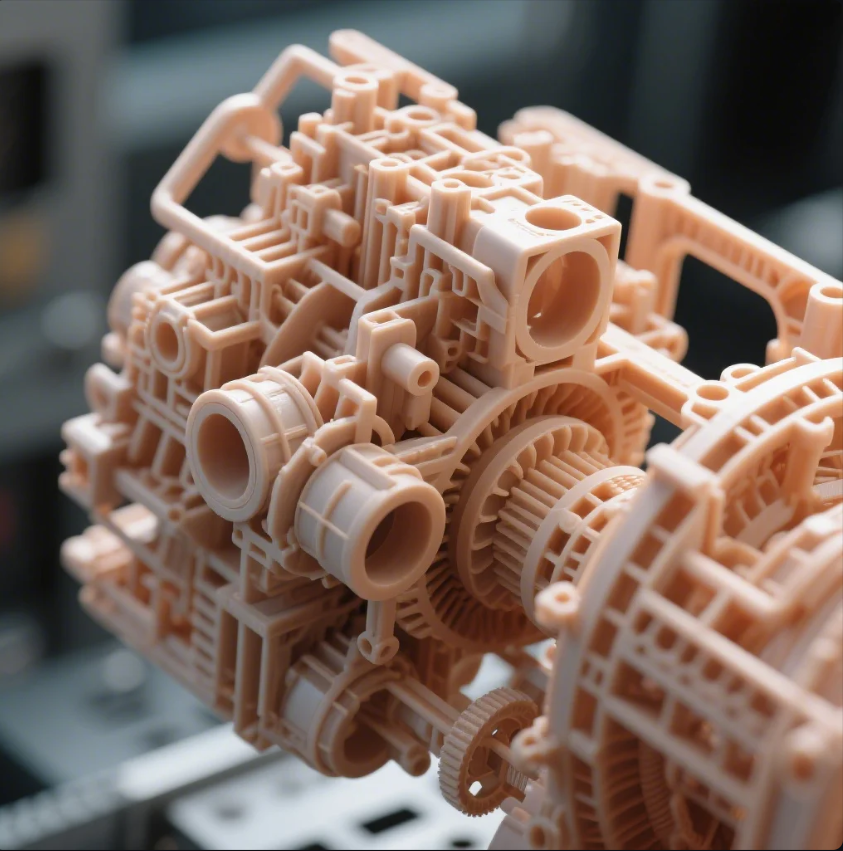

What Is the Difference Between CNC and SLS?

Leading paragraph: Traditional subtraction vs modern addition - these technologies complement rather than compete.

Snippet paragraph: CNC removes material from solid blocks (ideal for metals), while SLS 3D printing builds parts layer-by-layer (superior for complex plastics), with Prime offering both for complete manufacturing solutions.

Dive-Deeper paragraph:

Technology Cross-Over Points

Economic Batch Size Thresholds

| Part Complexity | SLS Advantage Range | CNC Advantage Range |

|---|---|---|

| Simple Geometry | 1-50 units | 51+ units |

| Medium Complex | 1-150 units | 151+ units |

| Highly Complex | 1-300 units | 301+ units |

Material Property Comparison

| Property | CNC Aluminum | SLS Nylon 12 | Notes |

|---|---|---|---|

| Tensile Strength | 310 MPa | 48 MPa | CNC 6.5x stronger |

| Elongation | 8% | 20% | SLS more flexible |

| Thermal Distortion | 180°C | 140°C | CNC handles heat |

| Density | 2.7 g/cm³ | 1.01 g/cm³ | SLS 63% lighter |

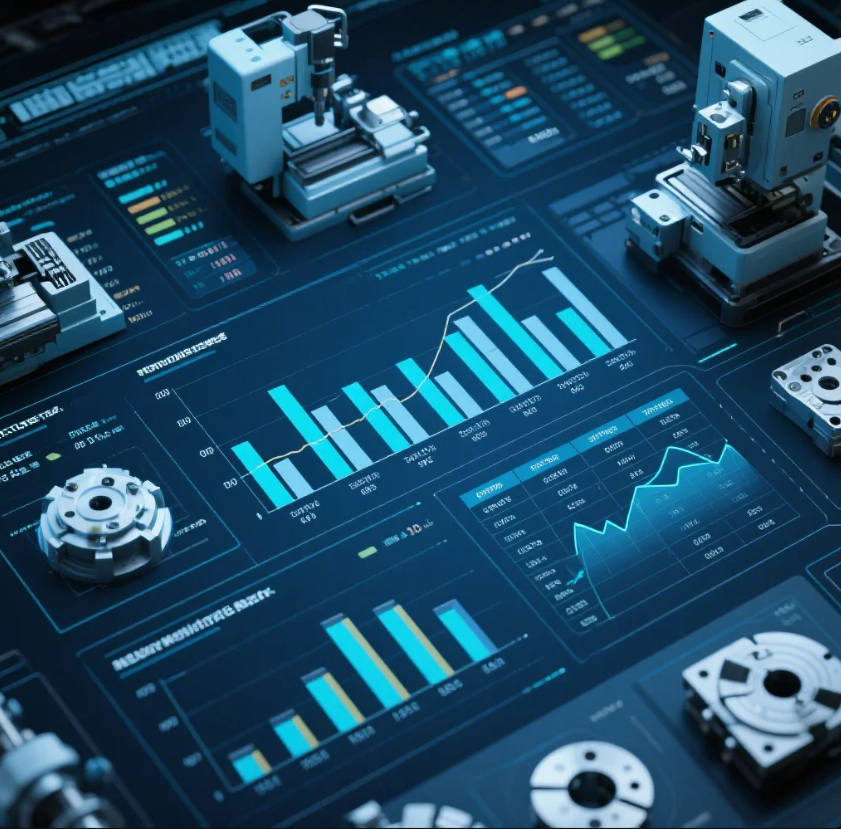

Is CNC Machining the Future?

Leading paragraph: Despite new technologies, CNC maintains critical advantages that ensure its ongoing relevance.

Snippet paragraph: CNC will remain fundamental for high-volume precision parts through 2040, with 68% of manufacturers planning hybrid CNC/additive cells, exactly like Prime's Industry 4.0 configured workshops.

Dive-Deeper paragraph:

The Future Manufacturing Ecosystem

Emerging CNC Advancements

1. Smart Machining (IoT Connected)

- Real-time tool wear monitoring

- Predictive maintenance alerts

- Adaptive cutting parameters

| 2. AI-Assisted Programming | Current Method | AI-Enhanced Version | Time Reduction |

|---|---|---|---|

| Manual CAM | Generative Toolpaths | 75% | |

| Trial Cuts | Virtual Machining | Eliminated | |

| QC Inspection | Computer Vision | 90% |

3. Sustainable CNC

- 30% energy reduction systems

- Metal recycling capabilities

- Minimum quantity lubrication

Conclusion

No single technology dominates - success lies in strategically combining CNC with its alternatives.

Let Prime Be Your Manufacturing Guide: Our engineers will:

- Recommend optimal processes for your parts

- Provide cost comparisons across technologies

- Deliver certified components through any method

[Request a free technology assessment] today to discover the best manufacturing approach for your specific requirements.

SEO Keywords:

- "CNC vs laser cutting precision comparison"

- "SLS 3D printing vs machining costs"

- "hybrid manufacturing future trends"

- "high-volume precision CNC services"

- "complex part manufacturing solutions"