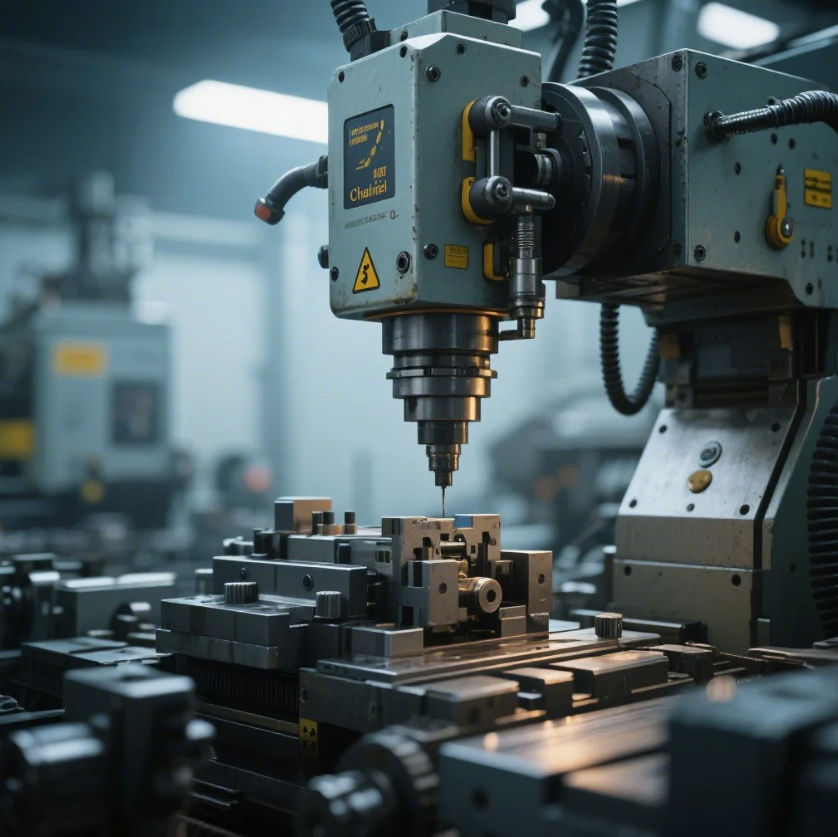

What Can a Hobby CNC Machine Do?

A hobby CNC machine can create precise, customized parts for small projects. Learn how it can transform your creations and improve your craft.

CNC machines are versatile tools used in various industries. They can help hobbyists create high-quality parts and prototypes with ease.

Looking for a simple yet powerful tool for your projects? A hobby CNC machine can take your creativity to the next level. Keep reading to find out how it can benefit you.

LOOP_START

What Would You Use a CNC Machine For?

A CNC machine is a perfect tool for many tasks. From simple cuts to intricate designs, it can handle various materials and applications.

CNC machines are used to carve, mill, or engrave materials such as wood, metal, and plastic. They are ideal for precision and consistency.

CNC machines can be used for personal projects like making models, custom parts, or even furniture. For businesses, they can be used to produce parts at scale with high precision. Whether you're making signs, tools, or prototypes, a CNC machine can be a valuable asset.

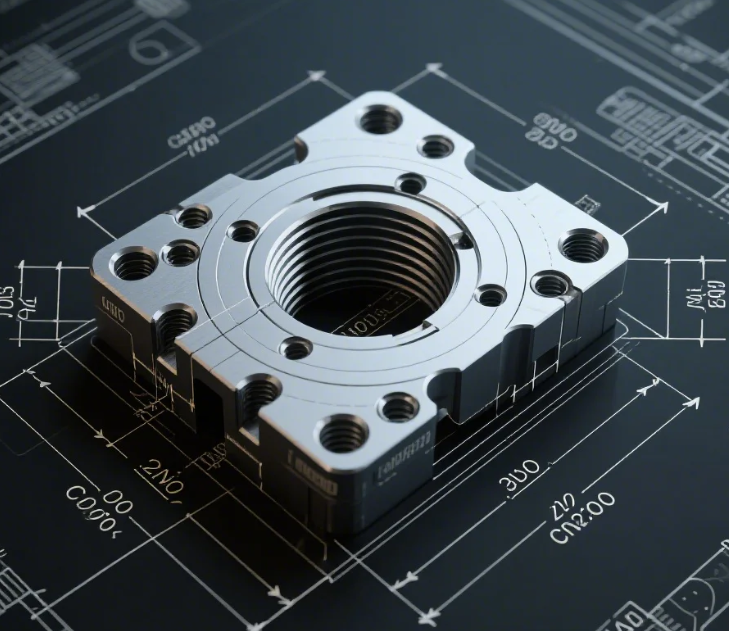

What Materials Can You Use with a CNC Machine?

CNC machines can work with a wide variety of materials, including:

| Material Type | Common Applications |

|---|---|

| Wood | Furniture, models, carvings |

| Metal | Tools, machine parts |

| Plastic | Prototypes, fixtures |

| Foam | Signage, packaging |

This broad material range allows you to create everything from small detailed designs to functional mechanical parts.

LOOP_END

What Kind of Business Can I Start with a CNC Machine?

If you're considering starting a business with a CNC machine, you're in luck. A CNC machine can be the foundation of a small business offering unique, custom products.

Starting a CNC-based business is profitable if you focus on precision, customization, and quick delivery.

With a CNC machine, you can start businesses such as:

- Custom Signage: Design and create personalized signs for businesses, homes, or events.

- Prototype Development: Offer rapid prototyping services for inventors or engineers.

- Jewelry Making: Use the machine to craft custom jewelry designs from metal or plastic.

- Custom Tools and Parts: Offer specialized parts or tools to manufacturers or other industries.

Key Factors for Success

To succeed with a CNC business, you need to focus on:

| Factor | Importance |

|---|---|

| Precision | Customers expect accuracy |

| Creativity | Offer unique, custom designs |

| Speed | Quick turnaround time |

The demand for precision products is high, and your CNC machine can meet these needs efficiently.

LOOP_END

What Are 3 Disadvantages of a CNC Machine?

While CNC machines offer many benefits, they also come with their challenges. Here are three potential disadvantages.

CNC machines require expertise, maintenance, and significant upfront investment, which can be limiting factors.

- High Initial Cost: Purchasing a CNC machine can be expensive, especially for high-end models. It's essential to weigh the benefits against the cost before purchasing.

- Complexity: While they are user-friendly, CNC machines still require technical knowledge to operate. Learning how to set up, program, and troubleshoot the machine can take time.

- Maintenance: Like any complex machinery, CNC machines require regular maintenance to ensure they continue to function properly. This can include cleaning, lubrication, and occasional repairs.

Despite these challenges, many hobbyists and businesses find the investment worthwhile due to the precision and productivity CNC machines offer.

LOOP_END

What Is a CNC Machine Capable Of?

A CNC machine is capable of producing high-quality parts and designs with extreme precision. From cutting to engraving, the machine handles various tasks.

CNC machines can handle a wide range of manufacturing tasks with greater efficiency and accuracy than manual labor.

Capabilities of a CNC Machine

CNC machines can perform the following tasks:

- Milling: Remove material from a workpiece using rotating tools.

- Turning: Rotate a workpiece while a cutting tool shapes it.

- Engraving: Create intricate designs or text on surfaces.

- Drilling: Precisely drill holes into materials.

- Cutting: Cut through different materials like metal, wood, or plastic.

Key Benefits of CNC Machines

CNC machines offer these advantages:

| Capability | Benefit |

|---|---|

| Precision | Produces parts with minimal error |

| Versatility | Can work with various materials |

| Speed | Processes jobs faster than manual work |

These capabilities make CNC machines indispensable in many industries, including automotive, aerospace, and manufacturing.

LOOP_END

Conclusion

CNC machines are versatile tools that enable hobbyists and businesses to create high-quality, customized parts with precision. Their capabilities, although accompanied by some disadvantages, provide great value for those looking to elevate their production.

Interested in starting a CNC-based business or enhancing your current operations? Contact Prime for high-quality CNC machining services. We provide quick delivery, exceptional precision, and reliable results. Get in touch with us now for a free consultation and customized quote.

One Response

You’ve written something that feels not just like knowledge, but like a quiet form of wisdom.