Is CNC Machining the Future?

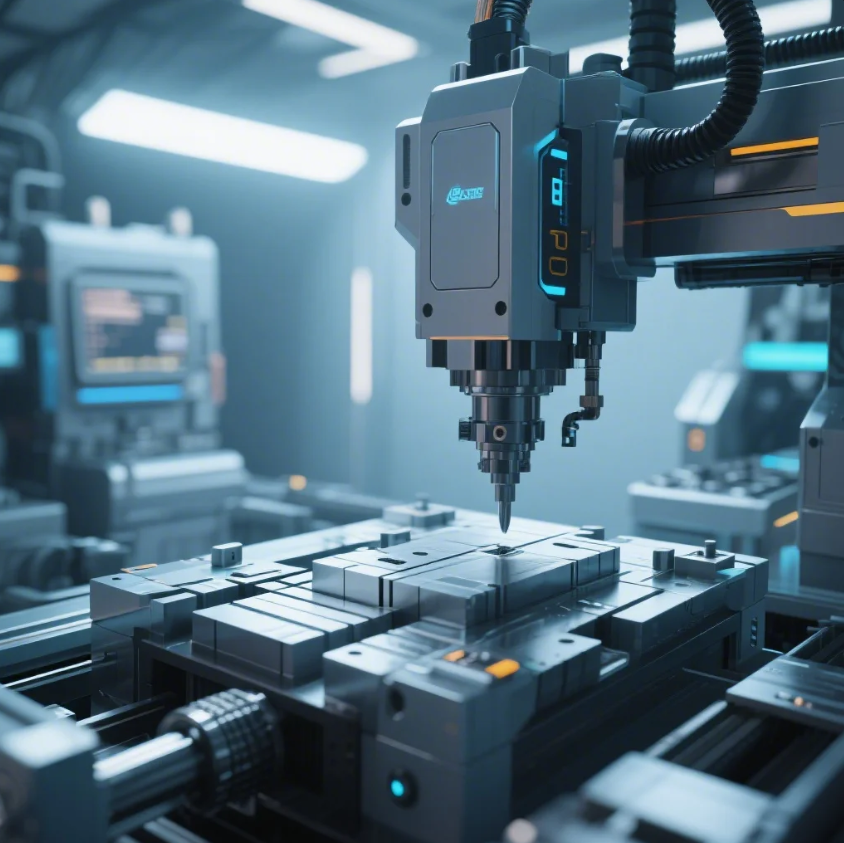

CNC machining has already proven itself as a critical technology in various industries. But what does the future hold for this powerful tool?

CNC machining offers unmatched precision and versatility. As industries evolve, the future of CNC machining looks promising, with even greater opportunities on the horizon.

Wondering if CNC machining is a solid career choice or business opportunity? Keep reading to explore its future potential.

LOOP_START

Is There a Future in CNC Machining?

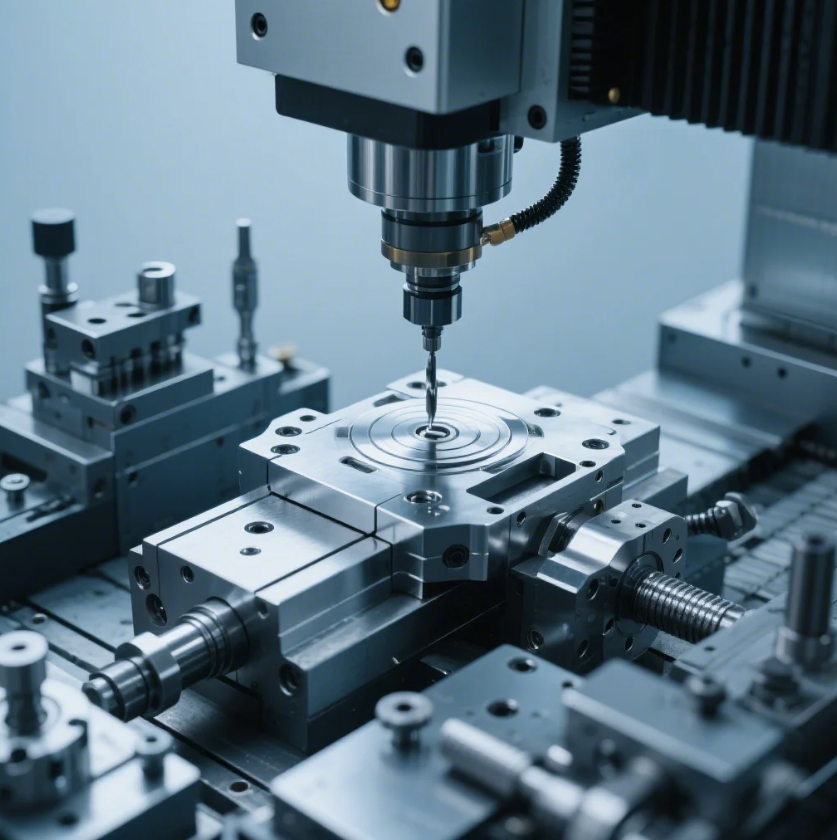

Yes, there is a bright future for CNC machining. As industries continue to advance, the demand for precision and customization increases.

CNC machining is essential for creating high-quality parts with precision. With advancements in technology, the role of CNC machines is becoming even more integral to various sectors.

As more industries require highly detailed components for everything from aerospace to automotive, the demand for CNC machining is projected to grow. The technology is also becoming more accessible with newer, smaller machines that can be used for smaller-scale operations or hobby projects.

The Growing Need for CNC Machining

Key industries benefiting from CNC machining include:

| Industry | How CNC Machining Helps |

|---|---|

| Aerospace | High precision parts for aircraft |

| Automotive | Manufacturing of engine components |

| Medical Devices | Creating custom implants or tools |

| Electronics | Precision parts for circuits |

CNC machining is here to stay, and its applications will only expand as industries continue to evolve.

LOOP_END

Is There a Future for Machinists?

Yes, machinists still have a future, but their roles are changing. While traditional machining skills are still valuable, modern machinists must be familiar with CNC technology.

The future of machinists is centered around working with automated machinery and understanding new technologies in CNC machining.

Machinists will still be required to oversee CNC machines, program them, and ensure that they operate correctly. The need for skilled machinists who can work with advanced CNC machines will grow as the industry becomes more automated.

How CNC Technology is Shaping the Role of Machinists

Key skills for future machinists include:

| Skill | Importance |

|---|---|

| CNC Programming | Essential for machine control |

| 3D Modeling | Design and prototypes in CAD systems |

| Robotics Integration | Managing automation and robotics |

As industries continue to adopt CNC technology, machinists will remain in demand but will need to adapt and continuously learn new skills.

LOOP_END

Is CNC Machining in High Demand?

Yes, CNC machining is in high demand across various industries. As manufacturing processes become more automated, the need for precision, reliability, and customization has skyrocketed.

The demand for CNC machining is increasing as more industries move toward automation and high-precision requirements.

Industries like aerospace, automotive, and electronics require parts that are both highly customized and produced quickly, which is where CNC machining excels. These industries will continue to drive demand for skilled CNC operators and businesses that specialize in this technology.

Key Factors Driving the Demand for CNC Machining

| Factor | Impact |

|---|---|

| Technological Advancements | Faster and more efficient machining |

| Precision Needs | Rising demand for high-precision components |

| Customization | Demand for unique, tailored parts |

CNC machining’s ability to meet these needs guarantees its role in the future of manufacturing.

LOOP_END

Can You Make a Living with a CNC Machine?

Yes, you can make a living with a CNC machine, but success depends on the scale of operations and market demand. CNC machines can be used for both personal and commercial purposes, offering a wide range of possibilities.

Using CNC machines for business can be lucrative if you focus on niche markets that demand high-precision, custom-made parts.

Small businesses can thrive with CNC machining, whether they focus on custom parts, prototyping, or specialized components. Many hobbyists and entrepreneurs start small CNC businesses and grow them over time.

How to Make a Living with a CNC Machine

Key business models include:

| Model | Description |

|---|---|

| Custom Parts Service | Creating parts for various industries |

| Prototyping | Offering rapid prototyping services |

| Small-scale Manufacturing | Producing small batches of products |

By offering specialized services or products, it’s possible to build a profitable business or side income with a CNC machine.

LOOP_END

Conclusion

CNC machining is undeniably part of the future. Its precision, versatility, and demand in industries like aerospace, automotive, and medical devices ensure its continued relevance. As technology advances, the need for skilled machinists and CNC operators will grow, opening up new opportunities for businesses and individuals alike.

If you’re looking to invest in CNC machining or need professional CNC services, Prime is here to help. Contact us for customized machining solutions that ensure quality and efficiency. Reach out today for a free consultation and quote!