What is the Easiest Position to Weld?

Welding positions vary, and understanding them is crucial when deciding on the easiest one to work with. Many factors, such as the type of material, joint design, and the welder's skill level, influence the ease of the task.

Snippet paragraph: Whether you're a beginner or experienced welder, knowing the easiest welding positions can help ensure better results. Find out the best options to improve your welding projects.

Transition paragraph: Keep reading to learn more about different welding positions, what makes them easier or harder, and which is best for your project.

What is 1G, 2G, 3G, 4G, 5G, 6G Welding Position?

Welding positions are categorized into six main types, often referred to as 1G, 2G, 3G, 4G, 5G, and 6G. These classifications refer to the orientation of the workpiece during welding and are essential for determining the difficulty level of a project.

Snippet paragraph: The 1G to 6G positions determine how the workpieces are positioned during welding. Learn what each of these positions means and how it impacts your job.

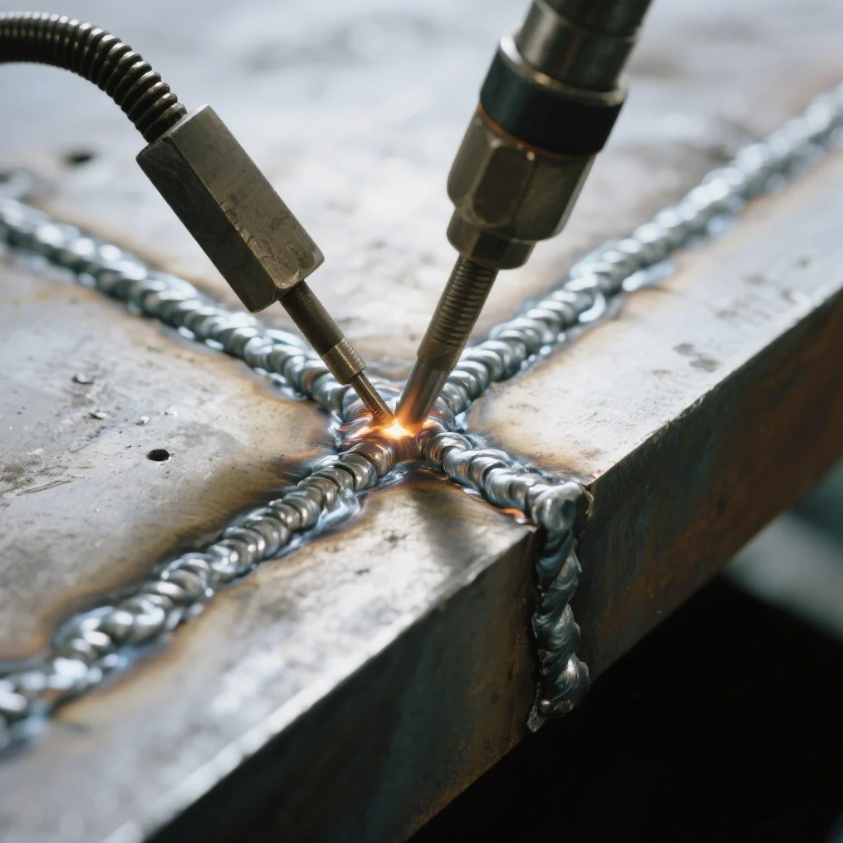

1G Position

The 1G position refers to flat welding, where the workpiece is positioned horizontally, and the weld is made on top of it. This is considered the easiest position because gravity works in your favor, making it easier to control the weld.

2G Position

The 2G position involves welding a workpiece placed in a horizontal position, but you weld along the side of it. It’s slightly more difficult than 1G since you have to work vertically to create the weld, but it's still relatively straightforward for most welders.

3G Position

In the 3G position, the workpiece is positioned vertically, and the weld is made along the vertical edge. This requires more control, as gravity pulls the molten weld pool down, making it harder to achieve consistent results.

4G Position

The 4G position refers to overhead welding, where the workpiece is positioned above the welder, and the weld is applied from below. This is considered one of the more challenging positions since gravity works against you and requires precise control to avoid sagging or excessive spattering.

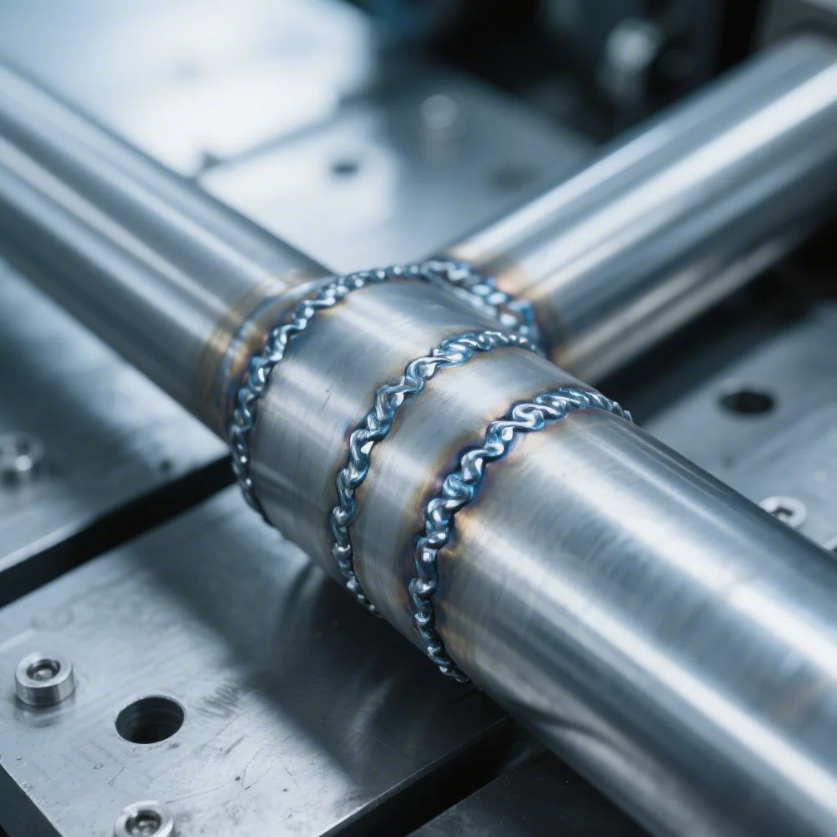

5G Position

The 5G position involves welding on a pipe that is positioned horizontally but remains fixed. The welder works at an angle, typically rotating the pipe to ensure the weld is consistent. This requires skill and experience to control the weld pool in a pipe environment.

6G Position

The 6G position is a combination of horizontal, vertical, and overhead welding, making it the most difficult position. This is typically reserved for advanced welders and is often used in critical applications like pipe welding.

| Welding Position | Description | Difficulty Level | Common Applications |

|---|---|---|---|

| 1G | Flat position (horizontal) | Easiest | Sheet metal, flat components |

| 2G | Horizontal, weld along the side | Moderate | Heavy-duty structures |

| 3G | Vertical position, weld on vertical edge | Challenging | Vertical structural joints |

| 4G | Overhead welding | Harder | Welding under structural beams |

| 5G | Pipe welding, horizontal with pipe fixed | Advanced | Pipe welding in industries |

| 6G | Combination of all positions | Most difficult | Advanced pipe welding |

What is the Easiest Joint to Weld?

The easiest joint to weld is the butt joint. In a butt joint, two pieces of metal are placed edge to edge, with little to no angle. This type of joint is straightforward because the welder simply needs to apply a straight, consistent bead along the joint.

Snippet paragraph: The butt joint is the easiest welding joint. Learn how its simplicity can help beginners and professionals alike achieve strong, reliable welds.

Why is the Butt Joint Easier?

The butt joint requires minimal positioning, and gravity doesn’t hinder the weld. Since it’s flat and simple, it’s easier for welders to control the heat and the welding pool, making it perfect for beginners or when speed is essential.

What is the Easiest Type of Welding Job?

The easiest type of welding job is MIG welding (Metal Inert Gas welding). MIG welding is often considered the most user-friendly welding method due to its simplicity and versatility. It allows for continuous welding without the need to manually feed filler rods.

Snippet paragraph: MIG welding is considered one of the easiest types of welding because of its simple process and minimal skill requirements. It’s ideal for beginners.

Why is MIG Welding Easier?

MIG welding is easier because the process uses a continuous wire feed, so the welder doesn’t have to worry about controlling a stick electrode or maintaining a proper arc length. This makes it particularly useful for light to medium-duty tasks and for those just starting in welding.

Common Applications for MIG Welding

MIG welding is frequently used in industries such as automotive repair, light structural work, and home repairs. It’s ideal for thin metals and non-ferrous materials like aluminum.

What Position is Hardest in Welding?

The hardest position in welding is the 6G position. This position combines elements of overhead, vertical, and horizontal welding, making it the most complex and demanding. It requires a high level of skill and control over the welding pool.

Snippet paragraph: The 6G welding position is the most challenging because it requires controlling multiple angles at once. It’s typically used for advanced welders working on critical projects.

Why is 6G the Hardest?

The 6G position is difficult because the welder must work in multiple orientations, often welding in tight spaces with minimal visibility. The weld pool is difficult to control in this position, especially in pipe welding. The angle changes constantly, requiring the welder to adjust technique and control throughout the job.

Advanced Welding Skills Required

Achieving a successful weld in the 6G position requires advanced skills such as knowing when to adjust the amperage, speed, and technique. It’s commonly used in high-stakes applications like offshore drilling, nuclear power plants, and pressure vessels.

Conclusion

In welding, choosing the right position is crucial to achieving quality results. The 1G position is the easiest, while the 6G is the most challenging. If you’re just starting out, consider focusing on MIG welding with butt joints for the simplest tasks. Once you’re ready to advance, tackling the more difficult positions will help you build your skill set and gain experience in the industry.

Ready to get your welding projects done efficiently? Contact Prime today for expert advice, custom solutions, and quick, reliable service. Get your free consultation and quote now!