Custom Mineral Parts factory since 1993

Get Factory Price Start From 100pcs

With over 30 years of experience, our large-scale production ensures you receive high-quality parts at cost-effective prices.

Take advantage of our 100pcs minimum order, helping you reduce costs while maximizing your business's profitability.

All of our products are ISO certified and adhere to strict quality standards, ensuring reliability and safety for your industrial needs.

Provide revolutionary custom mineral parts for your industry

What Sets Us Apart

We offer a wide variety of custom metal parts to meet your needs and budget.

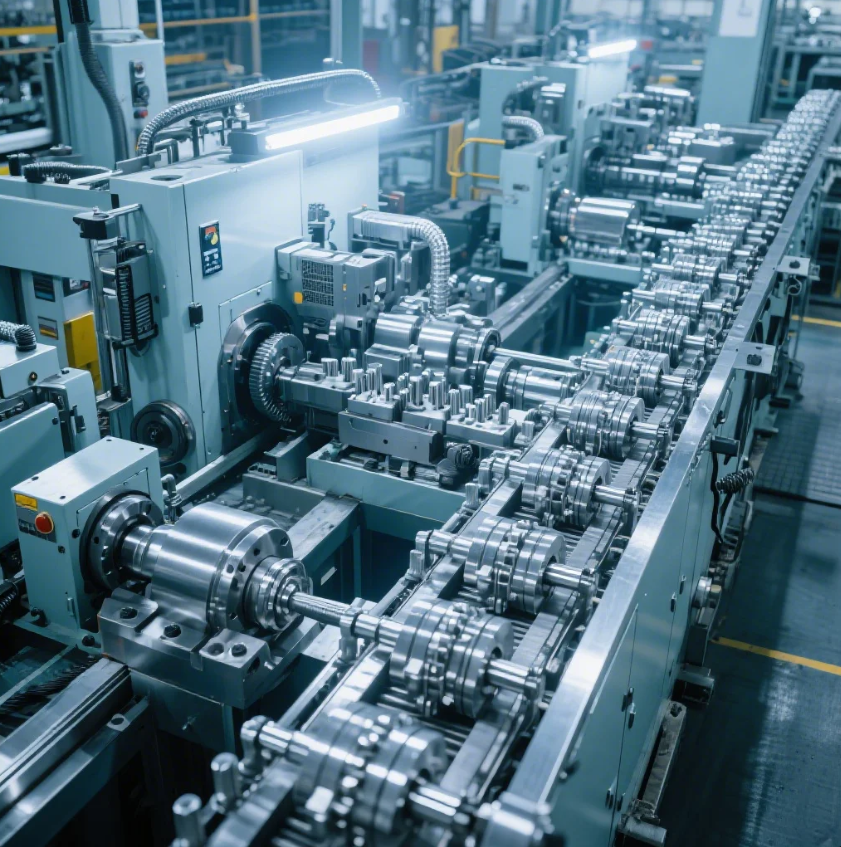

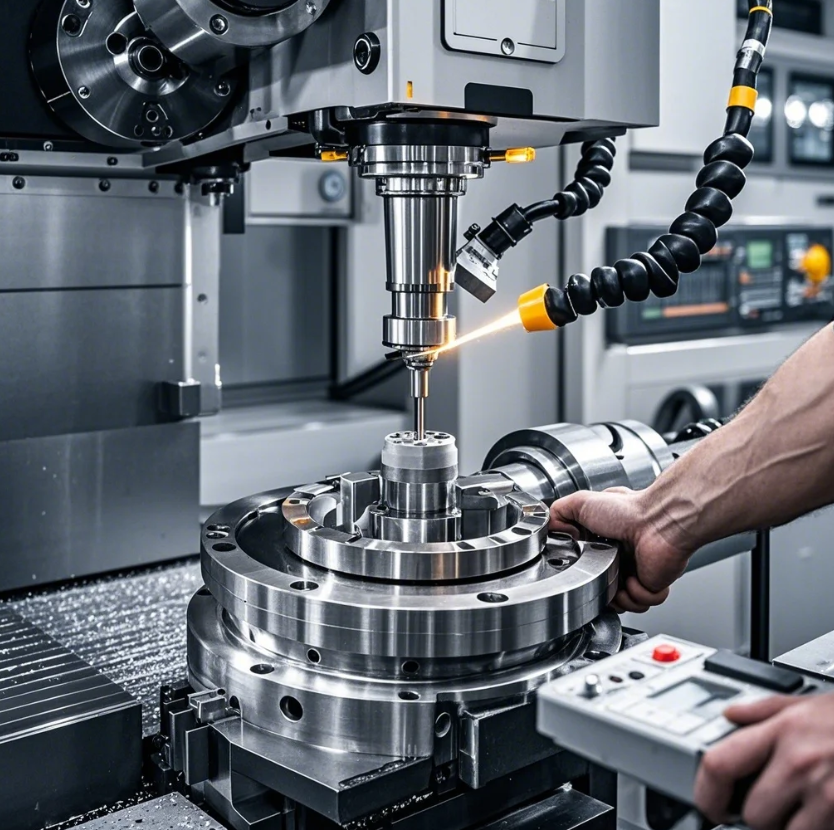

Advanced Production Workshop

We have first-class production facilities, covering a variety of processes, to meet the different metal mineral parts custom, efficient production and precision processing, to ensure that every detail of the parts are flawless.

Strict quality inspection

We implement the ISO 9001 quality management system throughout the process to ensure that each batch meets international quality standards and provides consistent quality assurance for your projects.

Flexible customized

With more than 30 years of industry experience, our design team and technical team work closely with you to tailor high-performance metal mineral parts to improve your product competitiveness.

Wide range of applications

Our metal and mineral parts are widely used in mining machinery, metallurgical equipment, construction engineering and many other fields, by domestic and foreign customers trust and praise.

We're There Every Step of The Way

We strictly follow the high standard of production process, to ensure that each metal mineral parts have excellent performance and reliable quality. The following are the main steps in the production of our metal and mineral parts:

Chapter 1

Material preparation

First of all, we will select the appropriate metal mineral raw materials according to the product design drawings. We use high-quality metal and mineral materials to ensure the durability and stability of the parts. All materials are subjected to strict quality control and inspection to ensure compliance with international standards.

Chapter 2

Cutting and shaping

The raw materials are laser cut or stamped to the desired shape and size. According to the product requirements, the use of stamping machines, shear machines or CNC machines to accurately cut and shape the material to ensure the dimensional accuracy of each part.

Chapter 3

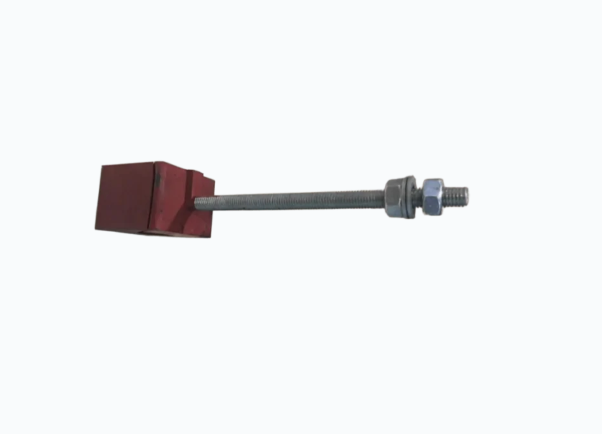

Welding and assembling

Where welding is required, parts are joined by hand or Robot welding. All welding points are strictly inspected to ensure the welding quality without defects and the overall structural stability of the parts.

Chapter 4

Surface Treatment

In order to enhance the corrosion resistance and beauty of the parts, surface treatment is an essential step. Common treatment methods include spraying, zinc plating, chromium plating, etc. . We use advanced surface treatment technology to ensure that the surface of the parts smooth, uniform and enhance their durability.

Chapter 5

Inspection and testing

Every metal part is subjected to strict quality inspection. We use precision instruments to test the size, strength and hardness of the parts to ensure compliance with industry standards and customer requirements. Only parts that pass the test can move on to the next stage.

Chapter 6

Packaging and shipping

Conforming parts are cleaned and packaged to ensure that they are not damaged during transport. We use high-quality packaging materials and provide customized packaging to ensure that the parts arrive safely at their destination.

Who we are

Partners for custom metalworking solutions

We hold ISO international quality certification, ensuring consistent quality in every product.

Our products are exported worldwide, including the USA, Canada, Europe, Australia, Southeast Asia, and the Middle East.

We are committed to helping you achieve your goals with reliable custom hardware solutions.

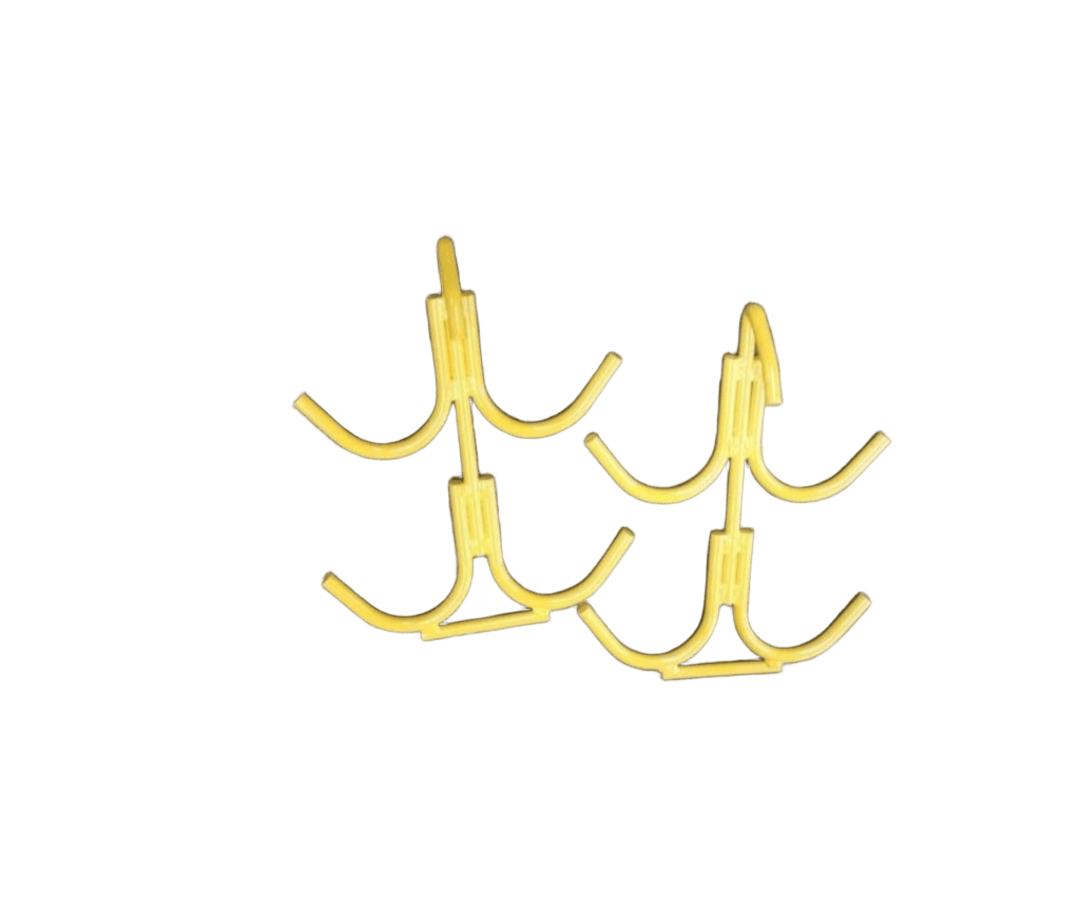

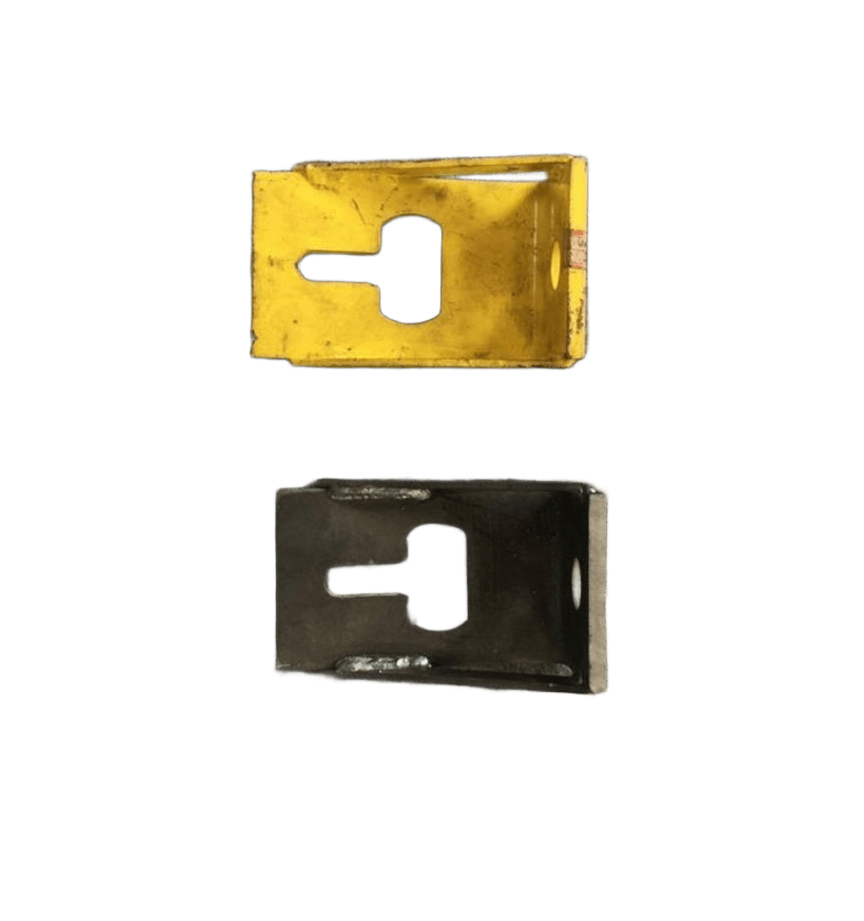

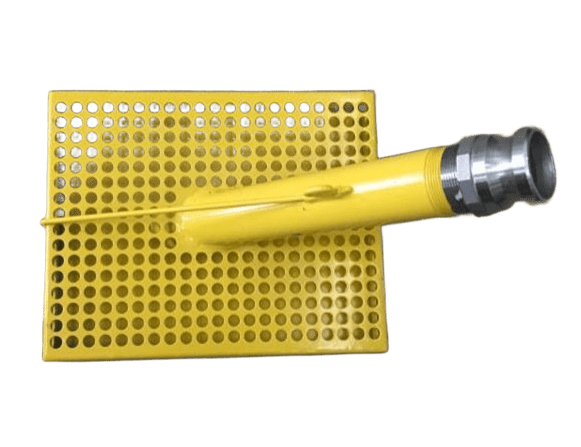

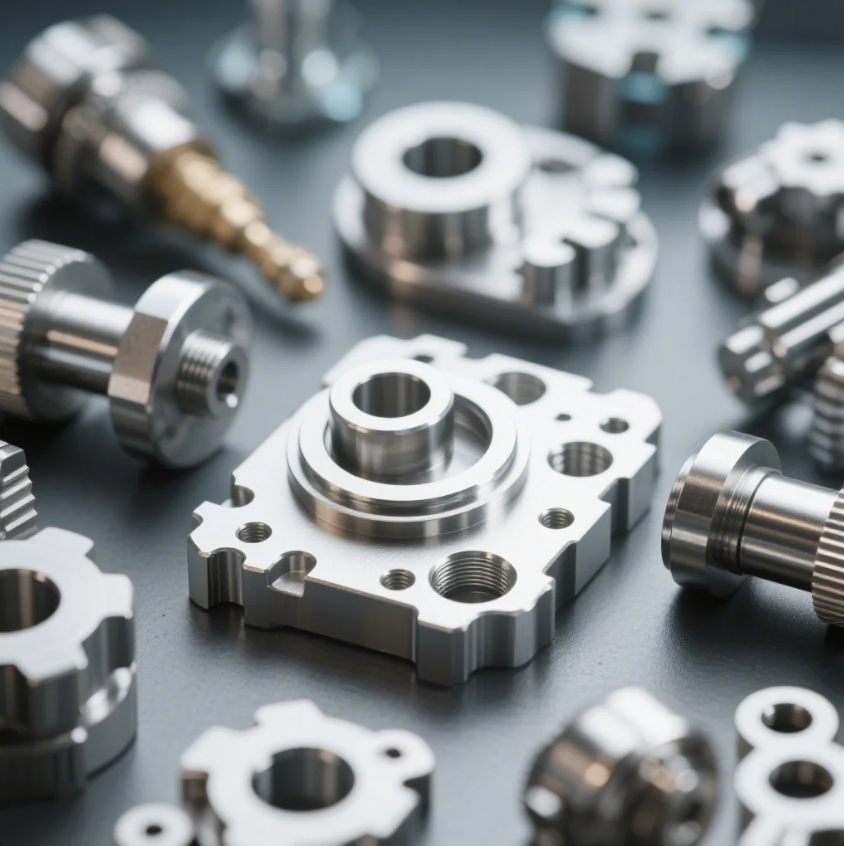

General Hot Selling Products

Mineral parts can be divided into several main types according to different processes, and each process has different characteristics. Here are some common mineral parts of the production process and its characteristics:

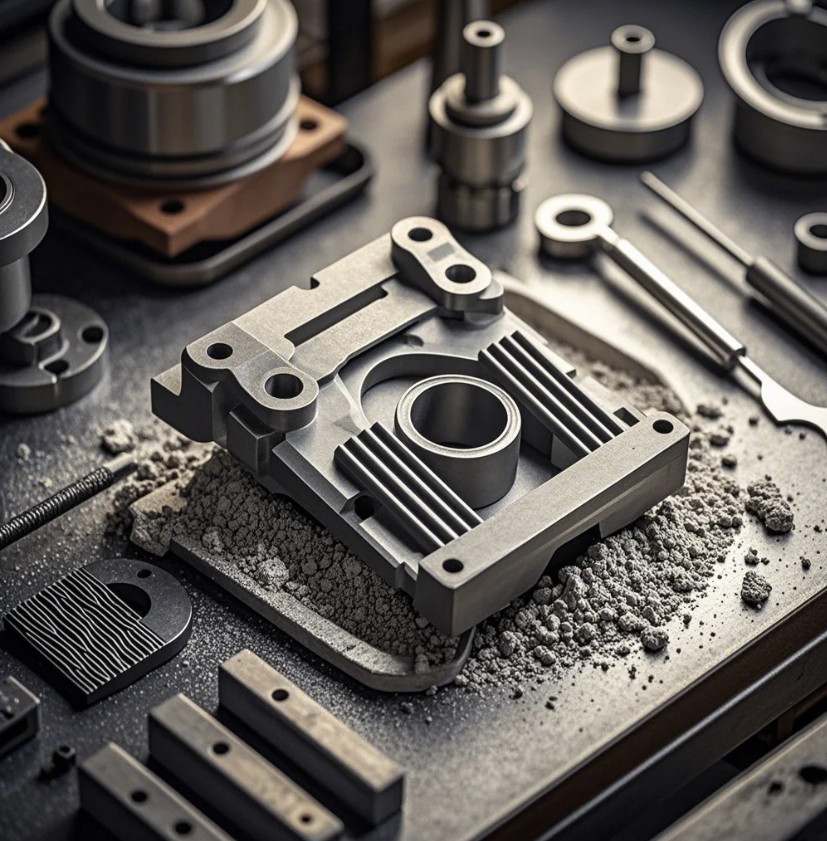

Casting process

Features:

Casting process by pouring molten metal or mineral materials into a pre-designed mold, cooling and solidification molding. The process is suitable for manufacturing mineral parts with complex shape and large size, which can effectively reduce material waste and improve production efficiency.

Applications:

Commonly used in mining machinery parts, such as casting mine car, ore crusher parts, hydraulic system parts.

Powder metallurgy process

Features:

The Powder metallurgy process produces mineral parts of a certain density and strength by compacting metal or mineral powders and sintering them at high temperatures. The process has the characteristics of high precision and high material utilization rate.

Applications:

Mainly used for manufacturing wear-resistant parts of mining machinery, such as gears, bearings, bushings, etc. , can withstand high load and high temperature.

Welding process

Features:

Welding process by heating, pressure or a combination of both, the mineral material contact surface melting and combined together to form a strong connection. Welding technology is widely used in the connection of metal structural parts.

Application:

Welding is often used in the maintenance and manufacturing of mining equipment, such as mining machinery frame, mining car and transport equipment structural parts, mining crusher and conveyor welding parts.

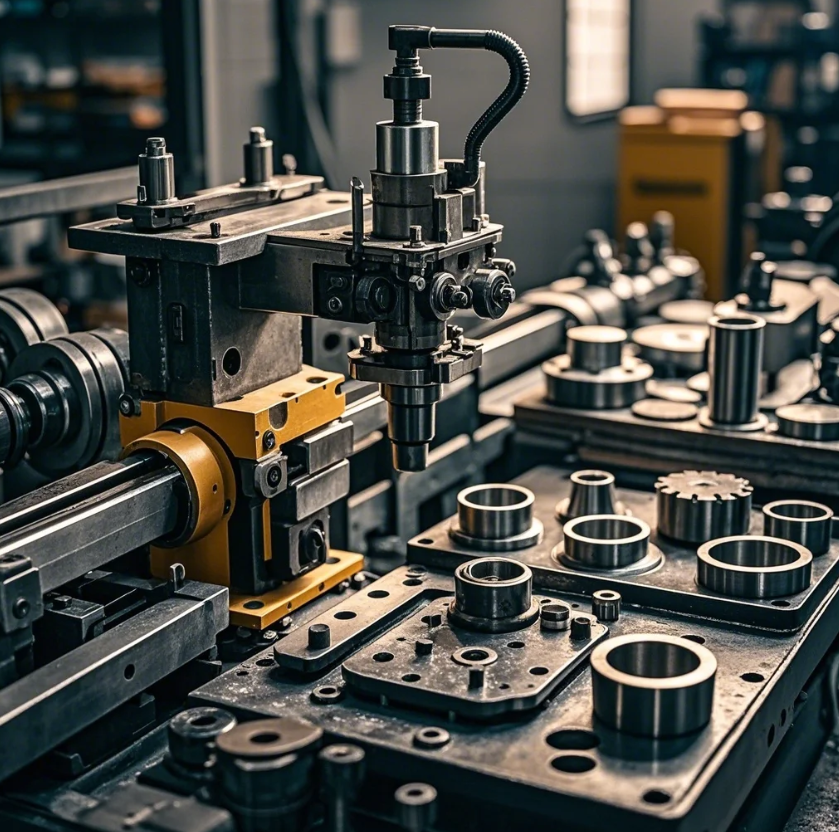

Stamping process

Features:

Stamping Process through the press and die for mineral materials (such as metal plate) stamping, shearing, bending and other operations, rapid formation of the required parts. The process has the advantages of high production efficiency, high dimensional accuracy and low cost.

Application:

For manufacturing mining equipment in the shell, shield, baffle and other parts, especially in the production of mining equipment external parts, commonly used stamping process.

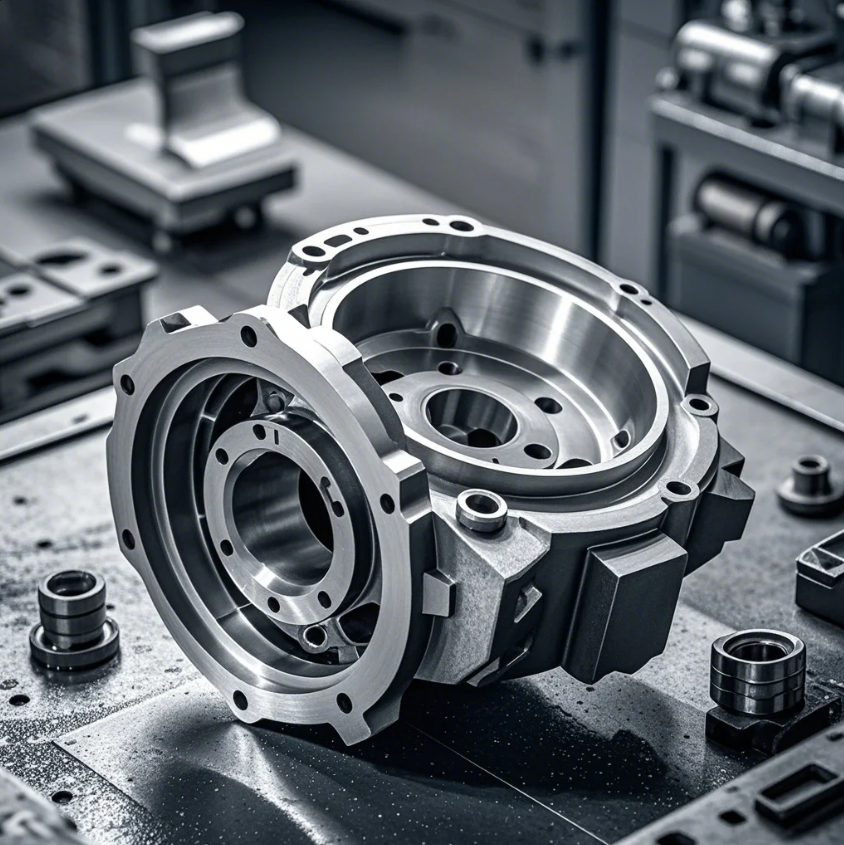

Precision casting process

Features:

Precision casting process usually adopts the lost wax method or sand casting, through the precision mold and high temperature operation, can produce complex shape and high precision parts.

Applications:

It is mainly used for manufacturing high precision parts of mining machinery, such as bearing block and gearbox housing of mining machinery, which need high strength and wear resistance.

Process of heat treatment

Features:

Heat treatment process by controlling the temperature and cooling rate, change the internal structure and properties of mineral materials, so as to improve its hardness, strength and wear resistance. Common heat treatment process including quenching, tempering, normalizing, etc. .

Applications:

Heat treatment process is used to improve the wear resistance and impact resistance of mineral parts, which is widely used in the manufacture of high-load parts such as mining tools, mining bits and mining gears.

Technology of mechanical processing

Features:

Machining process through CNC machine tools, lathes, milling machines and other equipment for mineral materials cutting, carving or processing, to achieve the required size and accuracy. The process provides highly accurate machining results.

Applications:

Machining for mining equipment precision parts, such as mining hydraulic system valves, precision gear, mechanical transmission parts, etc. .

Technology of laser cutting

Features:

laser cutting process through high-intensity laser beam will be precise cutting of mineral materials, can provide a very detailed cutting effect, and not easy to produce deformation.

Application:

laser cutting is often used in mining equipment precision parts, such as mining equipment protection cover, filter parts, especially the need for high precision and complex shape parts.

The Common Pitfalls When Purchasing

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

- Improper selection of materials: Improper selection of materials may lead to castings do not meet the strength, corrosion resistance and other performance requirements, affecting the service life.

- Poor design: Immature design can lead to difficulties in the production of mineral parts, increased costs, and delays in delivery.

- Supplier is not reliable: Some unprofessional suppliers may not be strict in quality control, resulting in substandard products or delivery is not timely.

Our Happy Clients

Frequently Asked Questions

Have a question? If you can’t find the answer here, our customer support team is ready to assist you. Reach out anytime!

How do you ensure the quality of hardware parts purchased from Prime?

At Prime, we prioritize quality by adhering to strict quality control measures throughout the production process. Our products are manufactured in accordance with ISO standards, ensuring consistency and reliability. We also offer sample testing to ensure the products meet your exact specifications before mass production, so you can be confident in the quality of your order.

Are Prime's customized hardware parts competitively priced?

Prime offers highly competitive pricing through efficient production processes and effective supply chain management. By optimizing these areas, we keep costs low without compromising quality. We provide personalized quotes based on your order size and specific requirements, ensuring you receive the best value for your investment.

Can Prime meet delivery deadlines?

Yes, Prime has extensive experience in international logistics, ensuring that orders are delivered on time. We work closely with you to develop a detailed production and shipping schedule tailored to your timeline. If you have urgent needs, we also offer expedited services to guarantee timely delivery and meet your business demands.

What kind of after-sales support does Prime offer?

Prime offers comprehensive after-sales support to ensure customer satisfaction. If there are any issues with the products after delivery, our customer service team is available to address your concerns and provide timely solutions. We maintain clear communication throughout the process to ensure a smooth and satisfactory experience for you.

How does Prime handle shipping and packaging?

Prime ensures that all products are securely packaged to prevent damage during transit. We use high-quality packaging materials tailored to the size and nature of the products. For large orders or specialized items, we offer customized packaging solutions to safeguard the products and ensure they arrive in perfect condition.

What customization options does Prime offer for hardware parts?

Prime specializes in providing tailored solutions to meet your specific needs. Whether it’s custom dimensions, materials, or special functionality, our engineering team works closely with you to bring your design to life. Share your requirements with us, and we’ll provide the best possible customization options to suit your project.

A Brief Self-Nomination, Why Choose Prime?

Choose Us, you will get cost-effective, high-quality, on-time delivery of mineral parts solutions.

Rich experience: We have more than 30 years of mineral parts production experience, can provide you with high-quality custom mineral parts.

Professional team: Our engineering team is familiar with the production process of mineral parts, and can provide accurate design and production services.

High quality assurance: We are ISO 9001 certified to ensure that each mineral component meets the highest quality standards.

Rapid Response: We are committed to providing fast sample production and production cycle, to ensure that your needs can be met in a timely manner.

Global Services: No matter where you are, we can provide you with quality services to ensure the smooth progress of your business.

Get in touch

Our promise is in our quality.

Share detailed information about your needs, including drawings, reference images, and any specific ideas or specifications you have in mind.

Based on your requirements and design, we’ll provide a custom solution and send you a detailed quote within 24 hours.

Once you approve the design and quote, we’ll begin mass production and take care of the shipping, ensuring timely delivery.

Get a Free Quote

Reach out to us for a free quote and expert advice on your custom hardware needs. At Prime, we’ll provide the right solution for your project, ensuring quality and precision every step of the way.