What is the difference between drawing and stamping?

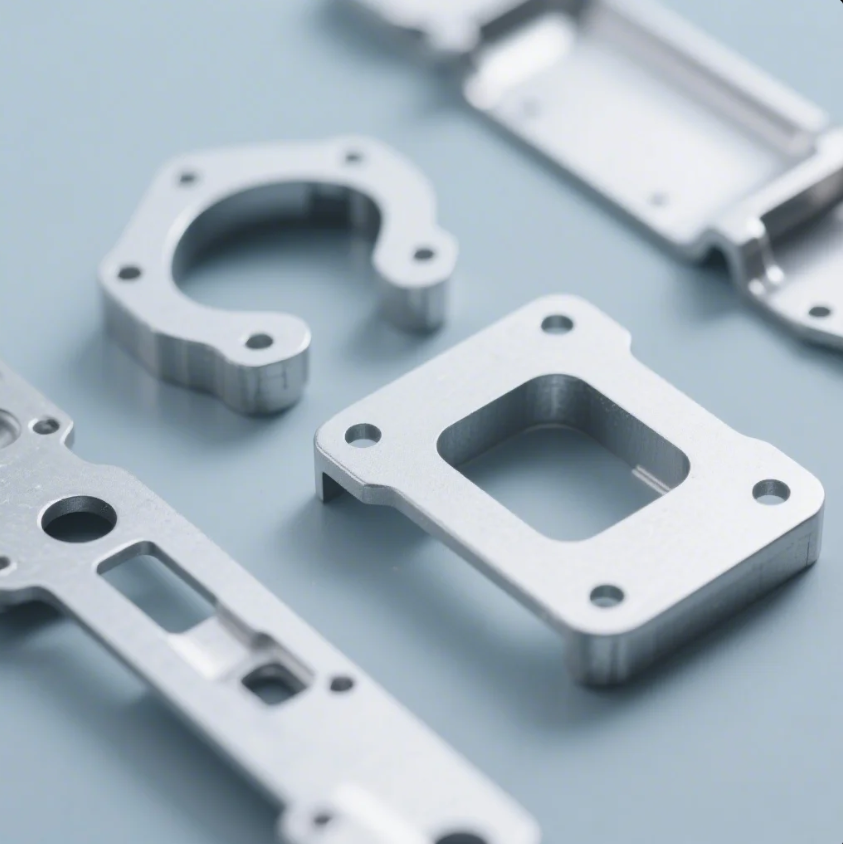

Stamping and drawing are two critical processes in metalworking, and understanding the difference between them is essential for anyone in the industry. Both processes have specific applications, advantages, and limitations, which can affect the quality, cost, and turnaround time of the final product. In this article, we will discuss the key differences between stamping and drawing, explore the process in more detail, and help you understand when and how each process is used in manufacturing.

Snippet paragraph: Stamping and drawing are often confused, but they involve different techniques. Learn the key differences in our detailed guide.

Transition paragraph: Let's explore how these processes work and the role they play in metal part manufacturing, from precision to material usage.

What does a stamped drawing mean?

Stamping is a metalworking process that involves shaping or cutting metal using a die and press. But what about "stamped drawing"? This term refers to the blueprint or design used in the stamping process. It outlines the exact specifications of the part, including dimensions, tolerances, and material types, guiding the production team in achieving precise results. The stamped drawing is the foundational document that ensures quality control and that the part is made to exact specifications.

Snippet paragraph: A stamped drawing serves as the detailed plan for the stamping process, ensuring that the finished product meets all specifications.

Dive Deeper:

A stamped drawing includes several key details to ensure the stamped part meets quality standards. It is an essential document in the manufacturing process. Stamped drawings typically include:

- Part Dimensions: Precise measurements to create a part that fits the required application.

- Material Specifications: Information about the material type and thickness to ensure the part's durability and strength.

- Tolerances: These are the permissible limits of variation in the part's dimensions, allowing for slight manufacturing discrepancies without compromising functionality.

- Process Notes: Specific instructions on how to handle the stamping, such as the sequence of operations or special requirements.

For example, a stamped drawing for an automotive part might specify the dimensions for a metal bracket, the type of steel to be used, and the required tolerance for each corner of the part.

Here's an example of a stamped drawing layout:

| Section | Details |

|---|---|

| Part Dimensions | Detailed lengths, widths, and thicknesses |

| Material | Steel, aluminum, or another metal |

| Tolerances | Specific range of permissible deviations |

| Special Instructions | Notes on special handling or processes required |

The stamped drawing serves as a critical guide in the production of metal parts, ensuring that all the required specifications are met consistently. It eliminates any ambiguity about the final product's shape, size, or materials.

What is the draw process of stamping?

The draw process in stamping refers to a method used to shape metal into a specific form by pulling the metal sheet through a die. This process is called "drawing" because the metal is literally drawn into a new shape. The draw process is often used for creating deeper shapes, such as cups, cans, or containers, that have a uniform thickness. This is ideal for parts that need to be formed into a deep, hollow shape or that require a more complicated geometry.

Snippet paragraph: Drawing is a technique used in stamping where metal is pulled into a mold to form a specific shape, often with deep contours.

Dive Deeper:

The draw process requires careful control of both the metal and the equipment to ensure that the final shape is uniform and free of defects. During drawing, the metal is subjected to significant forces that stretch it over the mold or die, which means material flow must be monitored closely to avoid issues such as tearing or wrinkling.

- Single-Stage Drawing: In this simpler process, the metal is drawn in one step to form the desired shape. This process is ideal for parts that require a single, shallow depth.

- Multi-Stage Drawing: This process involves several stages, with each stage progressively deepening or refining the shape. Multi-stage drawing is ideal for more complex parts, as it allows for greater control and precision at each step.

- Draw Ratio: This refers to the difference between the diameter of the starting blank and the final shape. A higher draw ratio requires more force and can cause material thinning, which must be controlled to maintain structural integrity.

Drawing can be challenging because it requires proper lubrication, tooling, and control of the drawing speed to ensure the desired outcome. Without careful attention to these factors, the drawn part may not meet the required standards.

Here’s an example of a typical draw ratio calculation:

| Blank Diameter | Final Shape Diameter | Draw Ratio |

|---|---|---|

| 100 mm | 80 mm | 1.25 |

In this case, a draw ratio of 1.25 means that the metal will be stretched by this factor during the drawing process. The higher the ratio, the more challenging it becomes to achieve a smooth and defect-free part.

What is the stamping process?

Stamping involves using dies and presses to shape, cut, or emboss metal sheets. Unlike drawing, which shapes the metal by pulling it, stamping can be used for a variety of operations, including punching, bending, and cutting. The process is fast and highly efficient, making it ideal for producing large volumes of parts with consistent quality.

Snippet paragraph: Stamping is a versatile process that shapes and cuts metal sheets using high pressure and precision dies, perfect for high-volume production.

Dive Deeper:

The stamping process can be divided into several key stages, depending on the type of part being produced. Here's a basic overview of the stamping stages:

- Blanking: The first step is cutting the metal sheet into a blank, which is the basic shape used for further operations. Blanking creates the foundation for all subsequent stamping processes.

- Punching: Holes or cuts are made in the metal blank using a punch press. This process is critical for parts that need specific holes or cutouts.

- Bending: Metal is bent into a particular angle or shape using a die. Bending is commonly used for creating angles or curves in the metal part.

- Embossing: Raised designs are formed by pressing the metal against a mold. This process is commonly used for creating logos, labels, or decorative patterns on parts.

- Forming: This process involves shaping the metal into more complex shapes, such as curves or deep indentations. This can include the draw process mentioned earlier.

Each of these stages requires precise control of pressure, speed, and temperature to ensure that the final part meets quality standards. The use of high-quality materials and proper tooling is essential to achieving accurate results in the stamping process.

In addition to the various stages, stamping can also be combined with other processes like welding or assembly to create complex parts. For example, metal components that require joining can be stamped and then welded for additional strength.

Which tool is used for stamping?

Stamping involves a combination of dies and presses to shape the metal. The most common tool used in stamping is a press machine, which applies force to the metal sheet and the die. There are different types of presses used, depending on the material and the complexity of the part being stamped.

Snippet paragraph: Press machines and specialized dies are the primary tools used in the stamping process. These tools apply force to shape the metal accurately and efficiently.

Dive Deeper:

There are several types of presses used in stamping, each offering different capabilities for specific applications:

- Mechanical Presses: These use a flywheel to store energy and deliver quick, high-force strokes. They're ideal for high-speed production where precision and efficiency are important.

- Hydraulic Presses: These use hydraulic cylinders to apply force, offering more control over the amount of pressure. These presses are better suited for more intricate or deep parts that require more gradual shaping.

- Pneumatic Presses: These use compressed air to create force, suitable for lighter and faster operations. Pneumatic presses are used for quick, low-force applications.

The die used in stamping is a custom-made tool that determines the final shape of the part. Dies can be simple or highly complex, depending on the type of part being produced. Dies are designed for specific operations, such as punching, bending, or forming, and they play a critical role in the final quality of the part.

Conclusion

Understanding the differences between drawing and stamping is key for anyone involved in manufacturing. These processes are vital to producing a wide range of metal parts, from simple cutouts to complex shapes with deep contours. Whether you're producing a large volume of parts or working on a custom project, Prime offers expert services in both stamping and drawing, ensuring that you get top-quality results. Reach out today for customized solutions and professional consultation!