What are the steps in stamping?

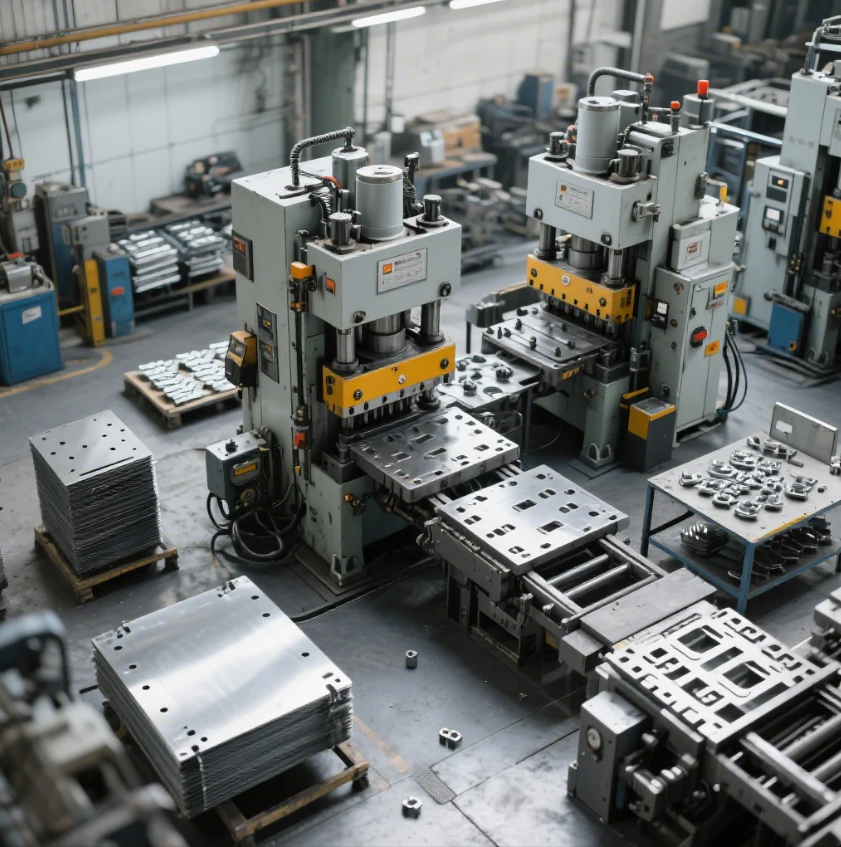

Stamping is a widely used manufacturing process that shapes metal sheets into desired parts using a die and press. It is used to produce a variety of metal components, from simple parts to complex, deep-drawn shapes. The process of stamping involves several stages, each contributing to the precision and quality of the final product. In this article, we will explain the steps involved in the stamping method and how each step works to create high-quality parts.

Snippet paragraph: Stamping involves a series of steps like blanking, punching, bending, and forming to shape metal into the desired part.

Transition paragraph: Let’s take a look at each of the steps in the stamping process to better understand how it transforms raw metal into the finished product.

What are the steps in stamping method?

The stamping method typically includes seven key steps, each playing a critical role in shaping the metal into the final part. These steps are performed in sequence to ensure precision and efficiency throughout the process. Let’s break down each step in the stamping process:

- Blanking: The first step is cutting the raw metal sheet into a blank. The blank serves as the base material for further operations.

- Punching: Punching creates holes or cutouts in the blank using a punch press.

- Bending: Bending shapes the metal by applying force at specific points to create angles or curves.

- Embossing: Embossing raises or indents patterns on the surface of the metal, often for decorative or functional purposes.

- Forming: Forming involves shaping the metal into three-dimensional parts, which can include deep-drawing, pressing, or stretching.

- Drawing: The drawing process pulls the metal into a mold to create deep shapes such as cups or cans.

- Finishing: The final step includes trimming excess material, cleaning the part, and applying coatings for a finished product.

Snippet paragraph: The stamping method involves blanking, punching, bending, embossing, forming, drawing, and finishing to shape metal into the final part.

Dive Deeper:

The steps in stamping are interconnected, and each step is critical to ensure the final part meets the required specifications. Let’s explore these steps in more detail:

-

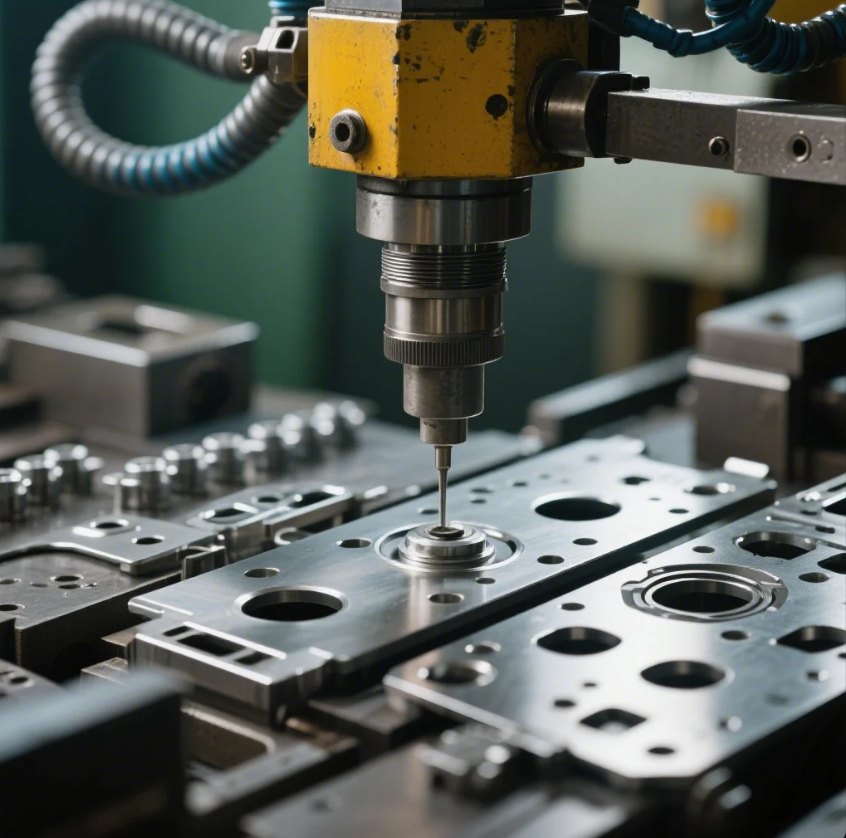

Blanking:

Blanking is the initial step where the raw material, typically a metal sheet, is cut into a blank. The blank is the basic shape from which all further operations will be performed. The precision of the blanking process is crucial as any inaccuracies can affect the alignment of subsequent steps. This step is done with a punch press and die set, ensuring the material is cut consistently to the right dimensions for the specific part. -

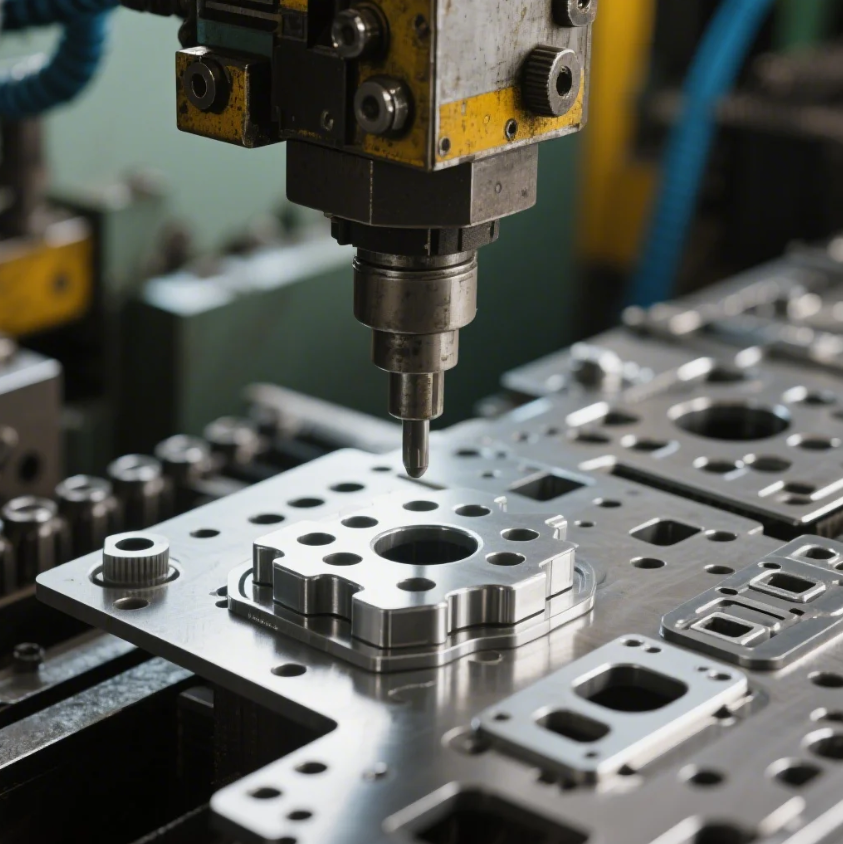

Punching:

Punching is performed after blanking and is used to create holes, slots, or other cutouts in the blank. The punching operation is often performed by a punch press, which pushes a punch through the metal sheet, creating specific features like bolt holes or slots. Punching is key for parts that require precise holes, and it is a relatively quick process that improves the part’s functionality. The accuracy of the punch and die set determines the precision of these holes. -

Bending:

Bending shapes the metal by applying force to it at specific angles, creating bends and curves. This step is essential for creating parts with angular shapes. A die is typically used to apply pressure to the metal at the point where the bend is needed. The bending operation can involve simple bends or more complex angles depending on the part design. This stage must be performed carefully to avoid cracking or warping of the material. -

Embossing:

Embossing creates raised or indented patterns on the metal surface. This process is commonly used for decorative features, such as logos, branding, or textured surfaces. Embossing can be done by pressing the metal against a mold or die that shapes the surface. This technique is also often used in industries where branding is important, like automotive or consumer goods. The embossing stage adds both aesthetic and functional value to the part. -

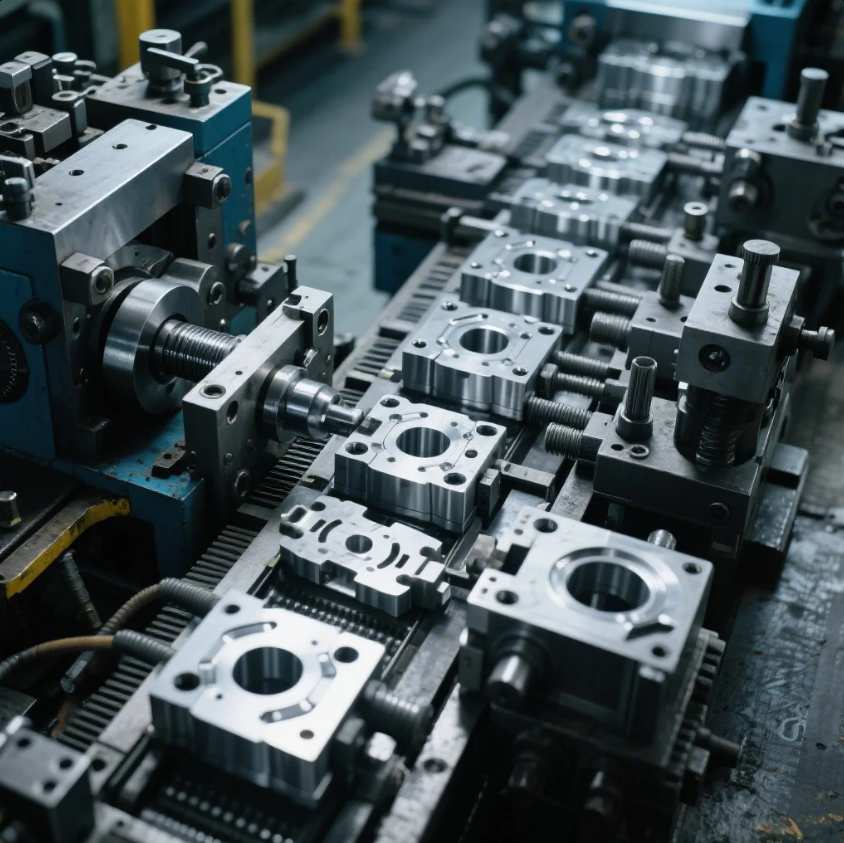

Forming:

Forming shapes the metal into three-dimensional parts by using techniques like stretching, pressing, or deep-drawing. This step allows for the creation of more complex shapes, such as deep cups or cylinders, that cannot be made through simple bending or cutting. Forming can involve multiple stages, with each stage progressively shaping the metal. For example, deep-drawing involves pulling the metal into a die to form a deeper part. Each forming process must be carefully controlled to prevent defects such as thinning or cracking. -

Drawing:

Drawing is a specific type of forming that is used to create deeper shapes. During this process, the metal is pulled through a die using a punch press, which stretches the material and forms the desired shape. The metal is drawn into the die, which gradually shapes it into a deeper part. The process requires careful control of the material to avoid defects like thinning, tearing, or wrinkling. Drawing is often used to create parts such as beverage cans, containers, and other deep-drawn components. -

Finishing:

Finishing includes several operations to prepare the part for use. This can include trimming excess material, cleaning the part to remove any residues, and applying protective coatings such as paint, anodizing, or plating. The finishing process ensures that the part is visually appealing, functional, and ready for assembly or use. The application of coatings can improve the part's resistance to corrosion, wear, and other environmental factors.

What is the process of stamping?

The stamping process refers to the combination of operations used to cut, shape, and form metal into the desired part. These operations are performed using high-pressure presses and dies, and each step is designed to progressively transform the raw material into a finished product. The stamping process can be used to produce a wide range of parts, from simple flat pieces to complex, deep-drawn components.

Snippet paragraph: The stamping process involves using dies and presses to cut, shape, and form metal into the desired part, ensuring precision and efficiency.

Dive Deeper:

The stamping process begins with the preparation of the raw material, typically a flat sheet of metal. Once the material is in place, the process begins with blanking to cut it into the appropriate size and shape. From there, other operations like punching, bending, and embossing are performed to create features and shape the material into the desired form.

One of the key benefits of the stamping process is its ability to produce large quantities of parts with consistent quality. Since stamping is typically performed using automated presses, it is highly efficient, making it ideal for mass production. The precision of the process ensures that each part meets the required specifications, with minimal variation.

What is stamping in drawing?

Stamping in drawing refers to the process of creating deep shapes or parts by pulling the metal through a die. The drawing process is a specific type of stamping that is used to create parts with significant depth, such as cups, containers, and other deep shapes that cannot be made through simpler bending or cutting methods.

Snippet paragraph: Stamping in drawing involves pulling metal through a die to create deep shapes like containers, cans, or other parts requiring significant depth.

Dive Deeper:

During the drawing process, the metal is pulled through a die using a punch press, which stretches the material and forms the desired shape. The metal is drawn into the die, which gradually shapes it into a deeper part. The process requires careful control of the material to avoid defects like thinning, tearing, or wrinkling.

There are two main types of drawing:

- Shallow Drawing: This involves creating parts with relatively shallow depths. It is typically used for forming parts that do not require significant depth.

- Deep Drawing: This process is used to create parts with greater depth, such as cans or containers. Deep drawing often requires multiple stages to ensure that the material flows properly into the mold and does not result in defects.

What are the steps in metal stamping?

Metal stamping is a versatile process used to create a wide range of metal parts. The steps involved in metal stamping are similar to those of general stamping but can be adjusted based on the type of metal used and the complexity of the part being produced. Here are the primary steps involved in metal stamping:

- Blanking: Cutting the metal sheet into the correct size.

- Punching: Creating holes or cutouts in the metal.

- Bending: Shaping the metal by bending it at specific points.

- Embossing: Adding raised or indented patterns to the surface.

- Forming: Creating deeper, more complex shapes.

- Drawing: Pulling the metal into deep shapes.

- Finishing: Trimming, cleaning, and adding coatings to the part.

Snippet paragraph: The steps in metal stamping are blanking, punching, bending, embossing, forming, drawing, and finishing to shape metal parts.

Conclusion

The stamping method is an efficient and versatile way to shape metal into a wide range of components. By following each of the steps in the stamping process, manufacturers can create precise and high-quality parts. Whether you need simple cutouts or complex, deep-drawn parts, Prime offers expert stamping services that guarantee top-notch results. Reach out to us today for a quote and discuss your metal stamping needs!