One-stop shop for custom precision metal stamping parts since 1993

Get Factory Price Start From 100pcs

With over 30 years of experience, our large-scale production ensures you receive high-quality parts at cost-effective prices.

Take advantage of our 100pcs minimum order, helping you reduce costs while maximizing your business's profitability.

All of our products are ISO certified and adhere to strict quality standards, ensuring reliability and safety for your industrial needs.

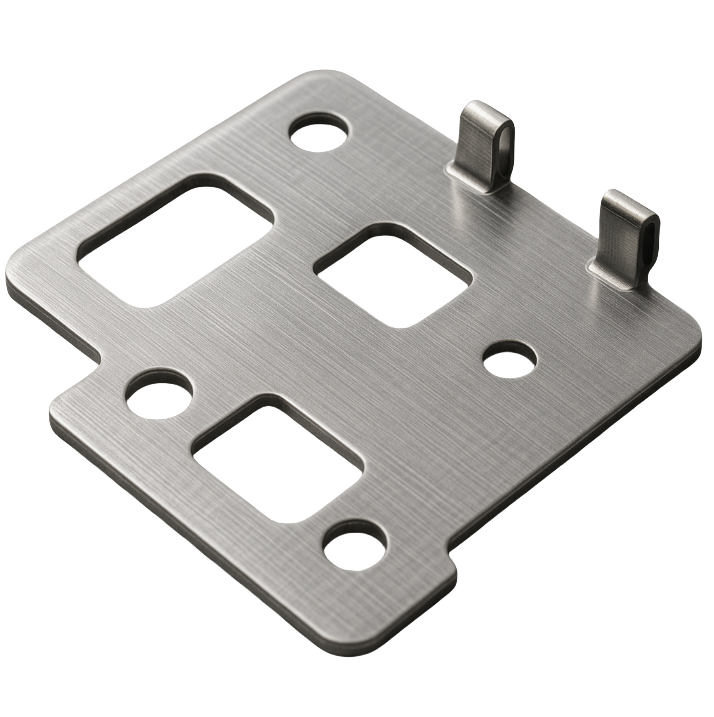

What Are Metal Stamping Parts?

Metal stamping parts are precision components manufactured by shaping sheet metal using mechanical or hydraulic presses and custom-designed dies. This cost-effective process creates complex geometries with tight tolerances, making it ideal for high-volume production across automotive, aerospace, electronics, and medical industries.

Stamping parts are metal components produced by shaping sheet metal using mechanical or hydraulic stamping presses and precision dies. These parts are known for their repeatability, dimensional accuracy, and suitability for large-volume production. The stamping process includes punching, bending, forming, and blanking operations.

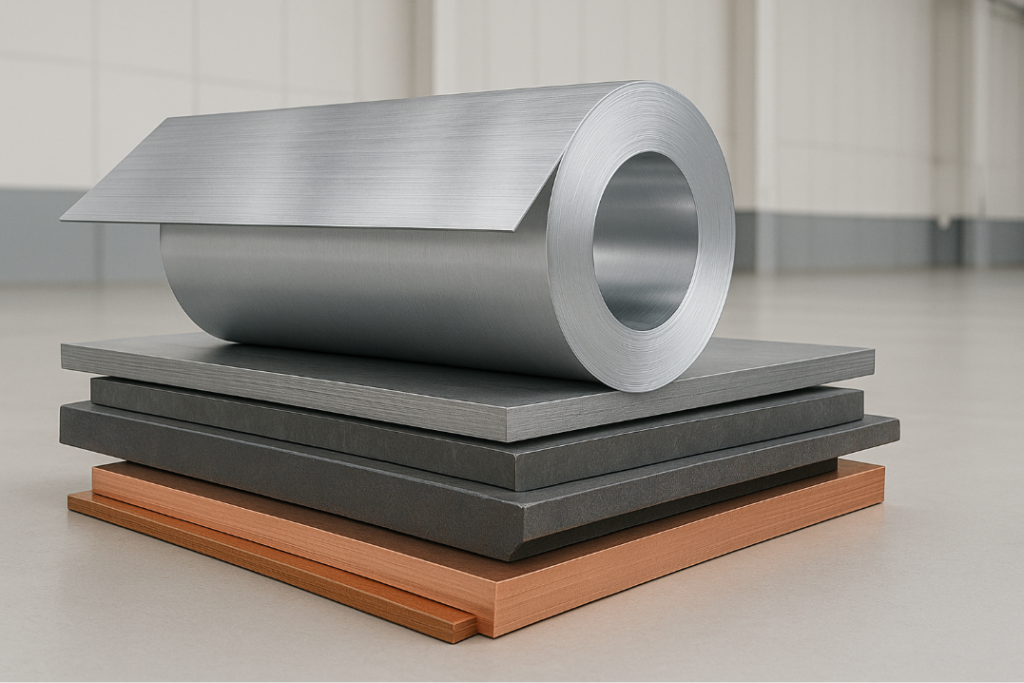

Materials Used in Metal Stamping

Different applications require different metal properties. Below are the most commonly used materials:

Stainless Steel

High corrosion resistance, excellent strength, and aesthetic appeal make it ideal for precision stamping parts used in harsh environments.

Carbon Steel

Affordable and strong, carbon steel is widely used in automotive stamping parts and industrial machinery.

Aluminum Alloys

Lightweight, corrosion-resistant, and easy to form — aluminum is ideal for aerospace and consumer electronics.

Copper and Brass

Known for excellent electrical conductivity and used in stamped metal components for electronic connectors and terminals.

Metal Stamping Process Parameters

| Process Type | Typical Applications | Material Thickness Range | Production Speed | Tolerance Capability |

|---|---|---|---|---|

| Progressive Die Stamping | Complex parts with multiple features | 0.1mm - 6mm | 20-1,500 strokes/minute | ±0.05mm |

| Deep Draw Stamping | Cylindrical and box-shaped components | 0.2mm - 3mm | 15-60 parts/minute | ±0.1mm |

| Four-Slide Stamping | Complex wire forms and small parts | 0.1mm - 2mm | 30-200 parts/minute | ±0.08mm |

Key Design Considerations for Metal Stamping

- Minimum Bend Radius: Typically 1-2 times material thickness to prevent cracking

- Minimum Hole Diameter: Generally equal to material thickness for optimal production

- Minimum Distance Between Features: At least 2 times material thickness for structural integrity

- Draft Angles: 0.5° to 2° recommended for deep drawn parts to facilitate removal

- Corner Radii: Sharp corners should be avoided; minimum radius of 0.4mm recommended

Understanding the types of stamping processes helps in choosing the right technique for your product design and performance goals.

Metal Stamping Applications: Case Studies

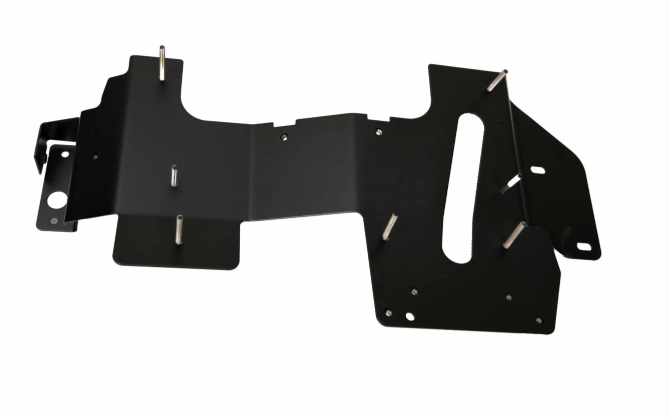

Automotive Bracket Manufacturing

A leading automotive supplier needed to produce 500,000 mounting brackets annually with strict tolerance requirements of ±0.1mm. By implementing progressive die stamping with in-die sensors for real-time quality control, we achieved:

- 35% reduction in production costs compared to previous machining process

- 99.8% first-pass yield rate

- Production rate of 2,000 parts per hour

- Material waste reduction of 42%

The high-strength steel brackets maintained consistent quality across production runs, meeting all automotive industry standards.

Medical Device Component Production

A medical device manufacturer required precision stainless steel components for a surgical instrument. Using deep draw stamping with specialized tooling, we delivered:

- Components with tolerances of ±0.025mm

- Surface finish of 0.4 Ra or better

- 100% compliance with FDA material requirements

- Elimination of secondary finishing operations

The seamless, burr-free components significantly reduced assembly time and improved device reliability.

Agriculture

Metal stamping parts in agricultural production greatly improve production efficiency, reduce maintenance costs, and ensure the efficient operation of the equipment.

Electronic

Through high-precision stamping technology, metal stamping parts can meet the needs of electronic products for lightweight, cost-effective and functional design.

Aerospace

High precision, high strength, excellent high temperature resistance, corrosion resistance and anti-fatigue performance, to ensure the reliability and safety of aircraft in extreme environments.

Construction

The metal stamping parts in the construction site not only improve the functionality and stability of the building, but also enhance the safety and durability of the building structure.

Machinery

Metal stamping parts not only improve the performance and efficiency of mechanical equipment, but also reduce the manufacturing cost and improve the reliability and service life of equipment.

Once the die is made, per-part cost is low even at high volumes.

Tight tolerances and consistent quality make it suitable for demanding industries.

Progressive dies enable thousands of parts per hour — ideal for mass production.

Complex geometries and features are achievable with minimal secondary operations.

Choosing a Reliable Stamping Parts Manufacturer

Proven quality system.

Faster turnaround and customization

Consistent performance

Expert support for DFM (Design for Manufacturing)

Prototype to mass scale

Inspection at every stage

Case Study: Automotive Customer Success

- We redesigned the component to reduce material waste by 18%

- Cut unit cost by 22%

- Delivered 50,000 parts with <0.2% defect rate

- Maintained on-time delivery record for 6 consecutive months

This buyer now sources 7 SKUs with us, saving over $120,000 annually.

What Buyers Should Ask Before Ordering

To ensure you’re getting the best value and quality, ask these questions before choosing your stamping parts suppliers:

- Can you provide rapid and accurate quotes?

- Do you offer custom tooling for non-standard designs?

- What’s your minimum and maximum order volume?

- Can I get free samples or prototype runs?

- What are your standard lead times for delivery?

- How do you ensure quality across batches?

- Do you support global shipping and after-sales service?

We are an ISO 9001 certified metal stamping manufacturer with over 30 years of global experience. With 10 advanced production lines, we serve clients across automotive, aerospace, and heavy industries.

Frequently Asked Questions About Metal Stamping Parts

What is the difference between progressive die stamping and deep draw stamping?

Progressive die stamping uses multiple stations to perform different operations sequentially on a metal strip, ideal for complex parts with multiple features. Deep draw stamping, however, pulls sheet metal into a die cavity to create hollow, seamless components with depth greater than their diameter, commonly used for cylindrical parts like cans and enclosures.

What materials are commonly used for metal stamping parts?

Common materials for metal stamping include stainless steel (for corrosion resistance), carbon steel (for strength and affordability), aluminum alloys (for lightweight applications), and copper/brass (for electrical conductivity). Material selection depends on the part's application, required properties, and cost considerations.

What industries use metal stamping parts the most?

Metal stamping parts are widely used in automotive (brackets, panels, chassis components), aerospace (structural components, brackets), electronics (connectors, shields, frames), medical (surgical instruments, device housings), and consumer goods industries (appliance components, hardware). Their cost-effectiveness for high-volume production makes them essential across manufacturing sectors.

What are the typical tolerances for metal stamping parts?

Metal stamping parts typically achieve tolerances of ±0.005 inches (0.127mm), with precision stamping capable of reaching ±0.001 inches (0.0254mm) for critical dimensions. Tolerances depend on material thickness, part complexity, tooling quality, and the specific stamping process used. Modern CNC-controlled stamping equipment can maintain consistent tolerances across high-volume production runs.

What are the cost advantages of metal stamping compared to other manufacturing methods?

Metal stamping offers significant cost advantages through high production speeds (thousands of parts per hour), minimal material waste, reduced labor costs through automation, and lower per-part costs at high volumes. While initial tooling costs can be substantial, they're amortized across large production runs, making stamping more economical than machining, casting, or 3D printing for high-volume manufacturing.

Our Happy Clients

Get a Free Quote

Start Your Project Today

Free consultation

Engineering support

Fast global delivery

Competitive pricing

Stop overpaying. Start scaling. Partner with a manufacturer that delivers results.

Get a Free Quote

And get a 24h response from our expert team. Let us help you reduce costs, improve quality, and accelerate your project timeline.