TEMPLATE_START

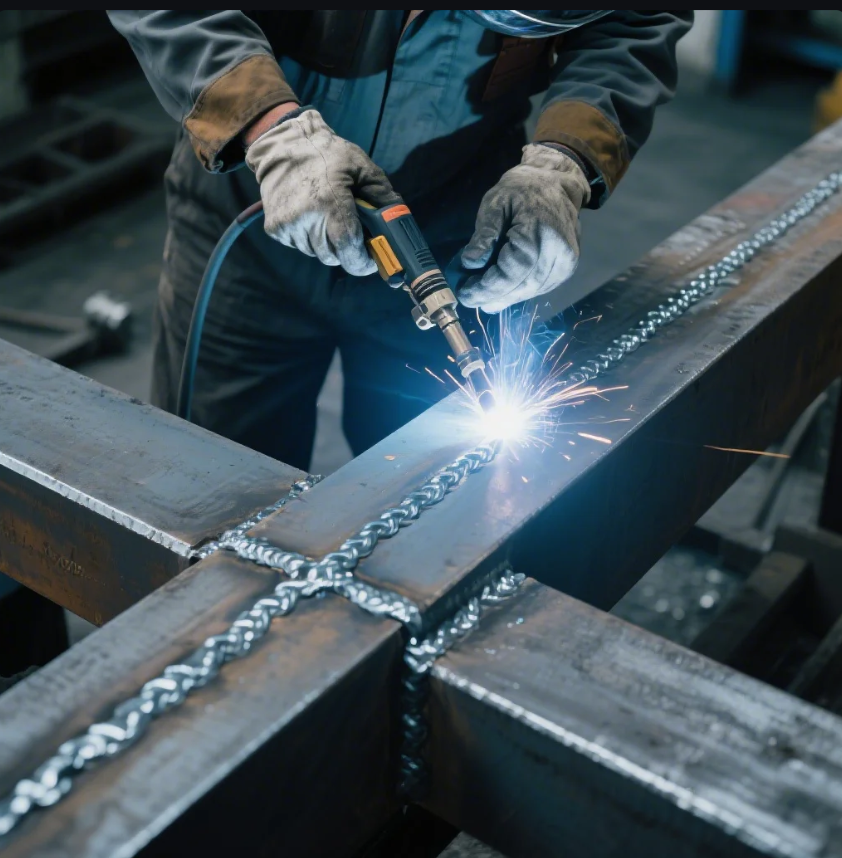

What is Stick Welding Called?

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is one of the most commonly used welding techniques. Whether you're a beginner or an experienced welder, understanding the basics of stick welding can help you achieve solid, reliable welds. But what exactly is stick welding, and why is it so widely used?

Snippet paragraph: Stick welding, or SMAW, is a simple yet versatile welding method that uses a consumable electrode coated with flux to create the weld.

Transition paragraph: Let's explore the term "stick welding," its connection to other welding methods, and why it's such a popular choice for a wide range of applications.

What is the name of stick welding?

The formal name for stick welding is Shielded Metal Arc Welding (SMAW). It involves the use of a consumable electrode, typically a metal rod coated with flux, which creates an arc between the electrode and the base material. The heat generated by the arc melts the electrode and the base metal, forming a strong bond once the material cools down.

Why is it Called Stick Welding?

Stick welding got its name due to the use of the "stick" electrode, which is a long metal rod that looks like a stick. The flux coating on the electrode serves multiple purposes: it shields the molten weld pool from contaminants and helps control the weld's flow, ensuring a clean, strong bond. The simplicity and portability of the stick electrode make SMAW a popular choice for construction, repair, and maintenance projects.

| Feature | Description |

|---|---|

| Electrode Type | Consumable metal rod with flux coating. |

| Welding Process | Creates an arc between the electrode and material. |

| Shielding | Flux coating protects from contaminants. |

Is Stick Welding MIG or TIG?

Stick welding is neither MIG nor TIG welding. Each of these processes is unique in how they create a weld. While MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding both use an electric arc to melt the base metal and filler material, there are key differences in the technique, the equipment used, and the type of welds they produce.

Key Differences Between Stick, MIG, and TIG Welding

- MIG welding uses a continuous wire fed through a welding gun and requires shielding gas to protect the weld pool.

- TIG welding uses a non-consumable tungsten electrode to create the arc and requires filler material, also with a shielding gas.

- Stick welding (SMAW) uses a consumable electrode that melts and becomes part of the weld, with flux coating providing protection from contaminants.

Stick welding stands apart for its ability to weld in outdoor conditions, where wind might blow away shielding gases used in MIG and TIG welding. It’s also known for being highly versatile, handling a variety of materials, and requiring less expensive equipment.

| Welding Process | Consumable Electrode | Shielding Method | Equipment Complexity |

|---|---|---|---|

| Stick (SMAW) | Yes | Flux coating | Simple |

| MIG | Yes | Gas shielding | Moderate |

| TIG | Yes (filler rod) | Gas shielding | Complex |

What is Stick Welding Terminology?

Understanding the terminology associated with stick welding can help you better communicate with fellow welders and understand the process. Here are a few common terms:

Common Stick Welding Terms

- Arc: The electric discharge that melts the electrode and base material to form the weld.

- Electrode: A metal rod coated with flux, which melts during welding to form the weld bead.

- Flux: The coating on the electrode that shields the weld from atmospheric contamination and helps with the welding process.

- Weld Pool: The molten material that forms as the electrode and base metal melt.

| Term | Description |

|---|---|

| Arc | Electric discharge for creating heat and fusion. |

| Electrode | Metal rod coated with flux for creating the weld. |

| Flux | Coating that protects the weld from contaminants. |

| Weld Pool | Molten material that solidifies into the weld. |

What are the Four Types of Welding?

Welding is a broad field, and there are several types of welding techniques. However, all welding methods typically fall into four main categories:

- Stick Welding (SMAW): As discussed, this process uses a consumable electrode and flux coating.

- MIG Welding (GMAW): Uses a continuous wire feed and shielding gas to weld metals.

- TIG Welding (GTAW): Uses a non-consumable tungsten electrode and a shielding gas for precise welding.

- Flux-Cored Arc Welding (FCAW): Similar to MIG but uses a flux-cored wire, which eliminates the need for shielding gas.

Overview of the Four Welding Types

| Welding Type | Electrode Type | Shielding Method | Complexity |

|---|---|---|---|

| Stick Welding | Consumable stick | Flux coating | Simple |

| MIG Welding | Consumable wire | Gas shielding | Moderate |

| TIG Welding | Non-consumable Tungsten | Gas shielding | Complex |

| FCAW | Consumable flux-core wire | Flux coating | Moderate |

Each welding method has its advantages depending on the type of work, the environment, and the materials involved.

Conclusion

Stick welding, or Shielded Metal Arc Welding (SMAW), is one of the most versatile and widely used methods for creating strong welds. Whether you're in construction, repair, or industrial maintenance, understanding stick welding and its terminology can significantly improve your welding skills. If you need high-quality industrial parts, Prime is here to help with a range of welding products.

Contact us today for fast delivery, top-notch quality, and expert assistance on all your welding needs.

TEMPLATE_END