What size wire do I need for aluminium welding?

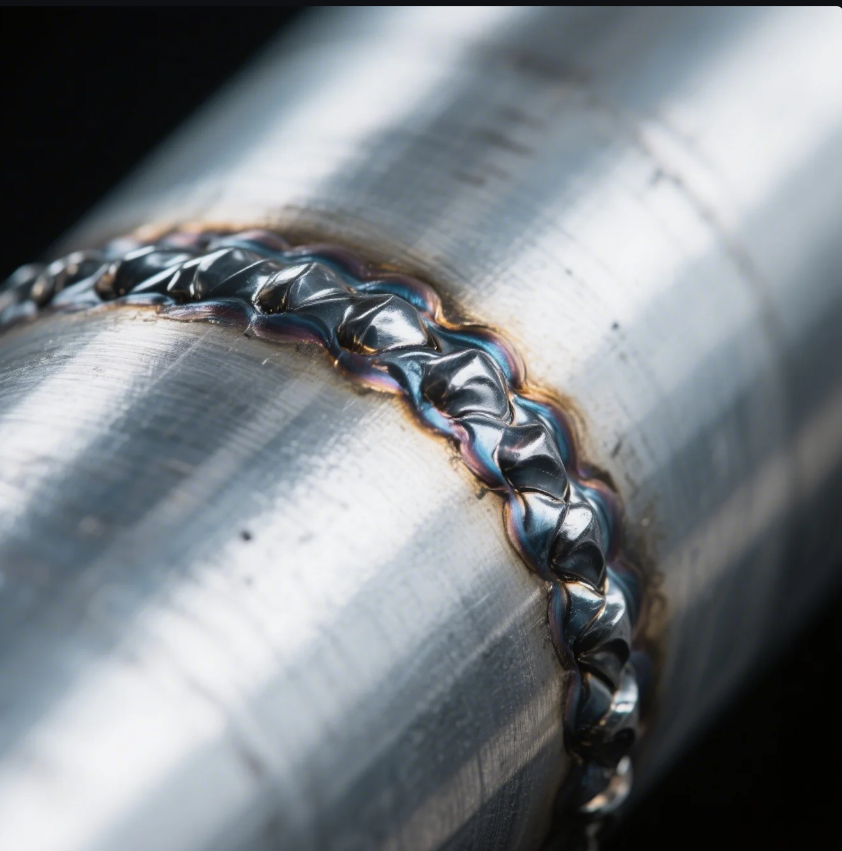

Using the wrong wire size causes feeding issues and weak welds.

The right aluminum welding wire size depends on your current, material thickness, and wire alloy—get it wrong, and your welds will fail.

Here’s how to choose the right wire for clean, strong aluminum welds.

What size wire do I need for a 200 amp service aluminum?

Higher amperage demands thicker wire—and better control.

For 200 amp aluminum welding, use 3/64" (1.2 mm) or 1/16" (1.6 mm) wire, depending on the application.

A client once insisted on using 0.030" wire for high-current jobs. The result? Overheating, poor arc stability, and massive feeding issues. After switching to the correct size, their defect rate dropped by 40%.

Recommended wire size for 200A aluminum welding

| Wire Diameter | Best Use Case |

|---|---|

| 0.035" (0.9 mm) | Thin panels, low-moderate current |

| 3/64" (1.2 mm) | General-purpose at 180–220 amps |

| 1/16" (1.6 mm) | Heavy-duty sections, 200–275 amps |

At Prime, we match every wire size to the job. When clients order CNC precision welding parts, we include a detailed welding procedure that ensures perfect results on aluminum alloys—even under high amps.

How many amps do you need to weld aluminum?

Amp needs vary—but aluminum generally requires more heat.

You typically need 1 amp per 0.001 inch of material thickness, plus extra for aluminum due to its high thermal conductivity.

One of our European customers struggled with undercut and poor fusion until we helped them adjust current based on aluminum’s heat sink behavior. Their process became smoother and more repeatable overnight.

General amp range by material thickness

| Material Thickness | Suggested Amps (MIG) | Suggested Amps (TIG) |

|---|---|---|

| 1/16" (1.6 mm) | 90–130 A | 70–110 A |

| 1/8" (3.2 mm) | 160–200 A | 130–180 A |

| 1/4" (6.4 mm) | 200–275 A | 180–250 A |

At Prime, we use this chart to tailor every welding plan for ISO-certified casting parts and aluminum assemblies. Our process control ensures no guesswork—just reliable output.

Can you weld 6061 aluminum with 5356 wire?

Yes—but only if ductility is not critical.

Yes, 5356 wire is commonly used to weld 6061 aluminum, offering good strength and corrosion resistance, but less ductility than 4045 or 4043.

When I first took over a sourcing project for an aerospace subcontractor, they requested 6061 aluminum parts joined with 4043 wire. But during salt spray testing, we found that 5356 performed better. We adjusted, and the results exceeded expectations.

Comparison of filler wires for 6061 aluminum

| Filler Wire | Strength | Ductility | Corrosion Resistance | Crack Sensitivity |

|---|---|---|---|---|

| 5356 | High | Moderate | Excellent | Low |

| 4043 | Medium | High | Good | Higher |

| 4045 | Medium | High | Good | Low (with heat) |

Prime supplies welding wire matched to customer specs. Whether you’re making custom aluminum welding parts or large frames, we help you select the right alloy for strength and long-term performance.

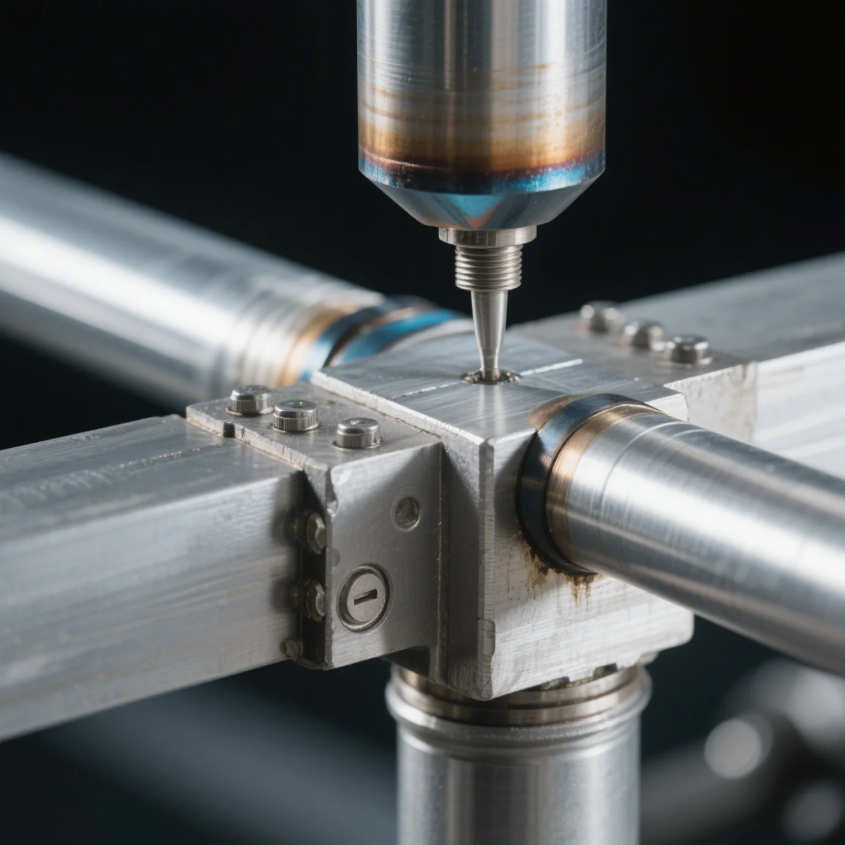

Do you need different wire to weld aluminum?

Yes—aluminum requires specific alloys and softer wire handling.

Yes, you need aluminum-specific wire (like 4043 or 5356), and a spool gun or push-pull system to avoid feed issues.

A client from the U.S. once tried welding aluminum using steel settings and wire—thinking all MIG wire was the same. After major burnback and tangled spools, they turned to us. We helped them set up a proper aluminum-ready feed system.

Key differences in aluminum welding wire

| Feature | Steel Wire | Aluminum Wire |

|---|---|---|

| Material | Mild/Carbon Steel | 4043, 5356, etc. |

| Wire Strength | Rigid | Soft, easily kinked |

| Feed System Required | Standard MIG gun | Spool gun or push-pull |

| Cleaning Requirement | Less critical | Must remove oxide |

At Prime, we don’t just ship products—we guide your whole process. For buyers sourcing custom stamping and aluminum welding components, we help configure the right wire, alloy, and feeding system to avoid rework and waste.

Conclusion

Choosing the correct wire size and alloy is key to successful aluminum welding.

Need expert guidance on aluminum welding wire, amps, or filler selection? Contact Prime today through our website. Get a free consultation, tailored solutions, and rapid delivery from our ISO-certified production team—trusted worldwide for quality and speed.