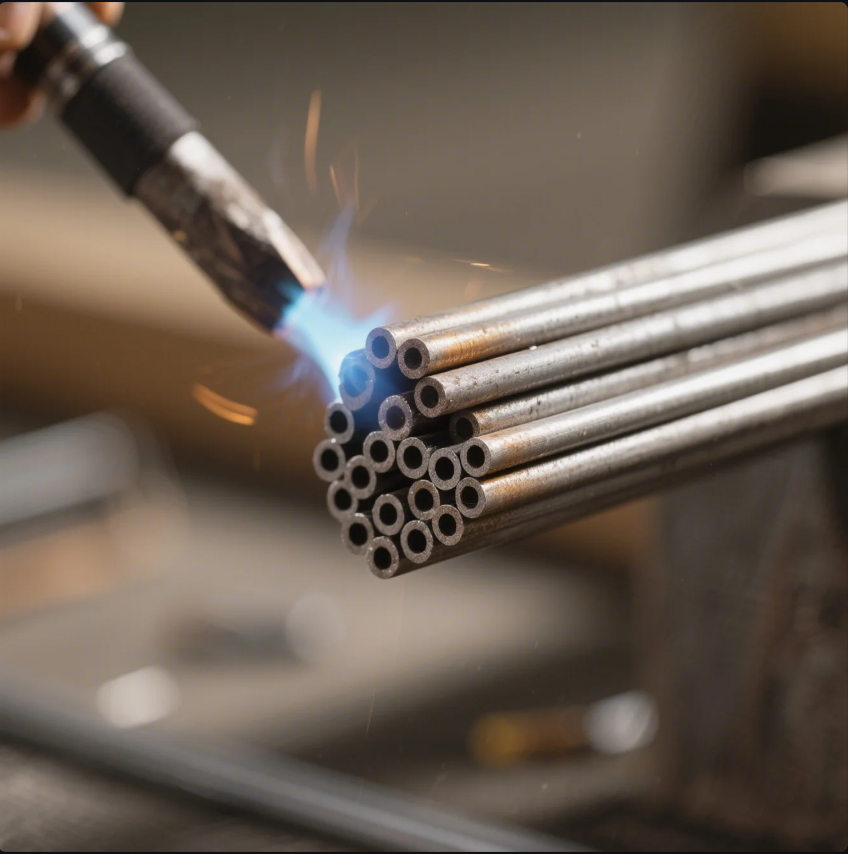

What does the last number on a welding rod mean?

Welding rod numbers aren’t random—they tell you everything.

The last number on a welding rod indicates the type of flux coating and the welding current it’s compatible with, such as AC, DC, or both.

Let’s decode the full number and understand how to use it in real jobs.

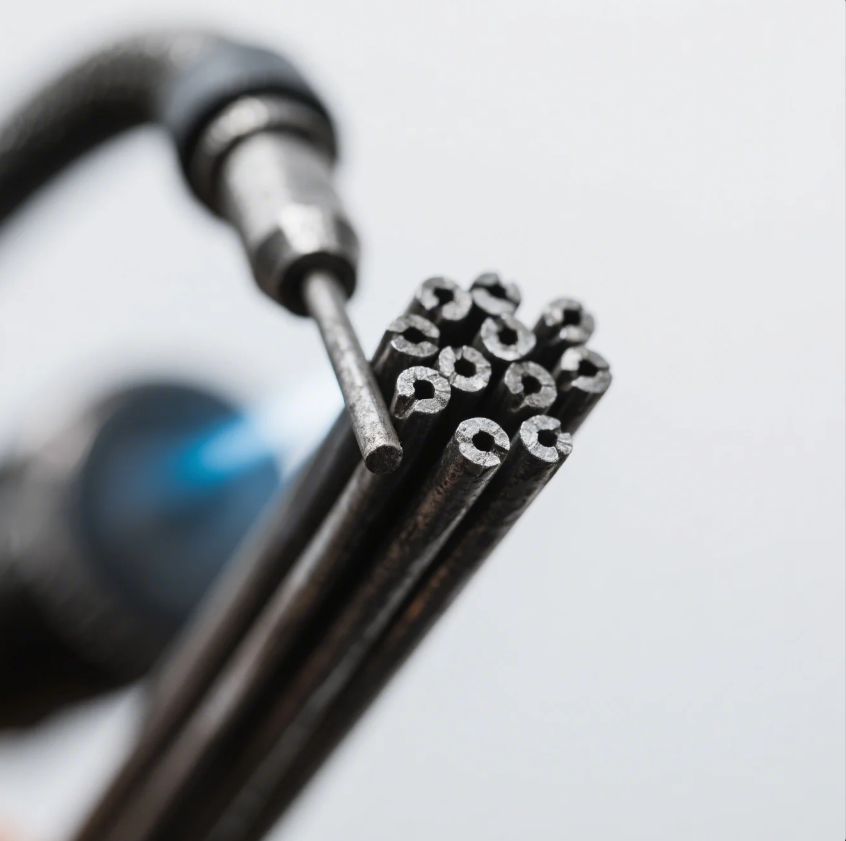

What does the last number on a rod mean?

It tells you how the rod behaves.

The last digit in a welding rod classification reveals its flux type and what kind of current (AC/DC) it can use.

For example, a 7018 rod ends in “8,” which means it’s a low-hydrogen, iron powder electrode compatible with both AC and DC+. This matters when selecting the right rod for your machine and joint type.

Last digit meanings for common electrodes

| Last Digit | Flux Type | Current | Key Features |

|---|---|---|---|

| 0 | High cellulose sodium | DC only | Deep penetration, fast-freeze |

| 1 | High cellulose potassium | AC or DC | Similar to 6010 but AC-compatible |

| 3 | Rutile potassium | AC or DC | Smooth arc, light fabrication |

| 4 | Rutile iron powder | AC or DC | Higher deposition, flat welds |

| 8 | Low hydrogen iron powder | AC or DC+ | Strong, clean, structural welding |

Prime includes WPS guides with every rod shipment, helping clients match rod types with amperage and current settings.

What does the last number in 7018 mean?

It makes 7018 unique among structural rods.

The "8" in 7018 means it's a low-hydrogen, iron powder electrode that runs on AC or DC+ and produces strong, clean, crack-resistant welds.

A bridge-building client used 7018 on a high-tensile structural job. The low-hydrogen flux helped them avoid cracking and pass every inspection.

Breakdown of E7018

- 70 = Minimum tensile strength: 70,000 psi

- 1 = All-position welding (flat, vertical, overhead)

- 8 = Low hydrogen coating, iron powder additive, AC/DC+ compatibility

| Property | Value |

|---|---|

| Weld strength | High tensile |

| Hydrogen resistance | Excellent |

| Slag behavior | Medium, easy to remove |

| Ideal application | Structural steel, code welding |

Prime supplies 7018 in sealed packs or rod ovens to ensure low hydrogen content stays intact during critical fieldwork.

What do the codes mean on welding rods?

It’s your cheat code to welding success.

Welding rod codes—like E6011 or E7014—describe the rod’s tensile strength, welding position, flux type, and current compatibility.

We regularly help clients decode these numbers to choose the right rod for repair, fabrication, or pipe welding. The wrong rod means poor fusion or failed inspections.

Welding Rod Number Breakdown (E7014)

- E = Electrode

- 70 = 70,000 psi tensile strength

- 1 = All-position welding (some codes use 2 = flat/horizontal only)

- 4 = Flux coating and current (rutile iron powder, AC/DC)

| Example | Meaning |

|---|---|

| E6010 | 60,000 psi, all-position, DC only, cellulose sodium |

| E6011 | 60,000 psi, all-position, AC/DC, cellulose potassium |

| E7014 | 70,000 psi, flat/horizontal, rutile iron powder, AC/DC |

| E7018 | 70,000 psi, all-position, low hydrogen, AC/DC+ |

Prime offers custom rod selection charts for clients ordering in bulk, especially for field or multi-process projects.

When to use 7014 welding rod?

Use it when you want speed, smoothness, and easy cleanup.

7014 rods are best used for clean, mild steel in flat or horizontal welding positions—perfect for fabrication, shop projects, and light structural jobs.

A Prime customer in Southeast Asia builds custom trailers using 7014s. Their welders love the smooth arc and fast deposit, cutting production time by 25%.

Best use cases for E7014

| Application | Why 7014 Is Ideal |

|---|---|

| Light fabrication | High deposition, easy arc |

| Shop welding | Works well on AC or DC machines |

| Decorative or visible welds | Smooth appearance, low spatter |

| Training/learning | Very forgiving arc behavior |

We recommend 7014 in our starter welding rod kits, ideal for learning or quick, clean production welding.

Conclusion

The last number on a welding rod tells you everything about its flux type, arc behavior, and power source compatibility.

Need help choosing the right rod for your job or understanding AWS codes? Contact Prime now through our website. We offer ISO-certified welding rods, expert selection tools, and fast worldwide delivery—trusted by welders in every industry.