What is the process of stamping a car and how does it impact automotive quality?

Automotive manufacturers often face delays, waste, and inconsistencies in body part production.

Car stamping is a multi-stage process that forms precise vehicle panels from flat sheet metal using high-tonnage presses.

Let’s break down how it works—and why getting it right is essential to car safety and performance.

LOOP_START

What are the 7 steps in the stamping method?

Missing a step in the stamping process can lead to weak or misaligned car parts.

The stamping method in automotive production follows seven critical steps from raw metal to final shape.

The 7 key steps explained:

| Step | Description |

|---|---|

| 1. Material Blanking | Cutting large coils into smaller blanks for forming |

| 2. Lubrication | Applying oil to reduce friction and wear on dies |

| 3. Positioning | Accurately feeding blanks into stamping machines |

| 4. Drawing | Forming the blank into a three-dimensional shape |

| 5. Trimming | Removing excess material from edges |

| 6. Piercing | Creating openings (windows, mounting holes) |

| 7. Flanging | Bending edges for joining or added rigidity |

Why step control ensures final quality

Each step needs tight control. At Prime, our progressive dies combine several of these steps in one machine cycle—cutting production time while increasing part precision. Our U.S. automotive clients rely on this for door skins, fenders, and structural brackets with zero warping.

LOOP_END

LOOP_START

What is the stamping procedure?

Many new buyers confuse the stamping procedure with single-step pressing.

The stamping procedure includes all mechanical actions required to transform sheet metal into auto parts using dies and presses.

Standard automotive stamping procedure

| Phase | Action Taken |

|---|---|

| Pre-Processing | Material inspection, cutting, lubrication |

| Setup & Alignment | Tooling setup and sensor calibration |

| Stamping Execution | Multiple stamping operations using progressive or transfer dies |

| Post-Processing | Trimming, piercing, inspection, cleaning |

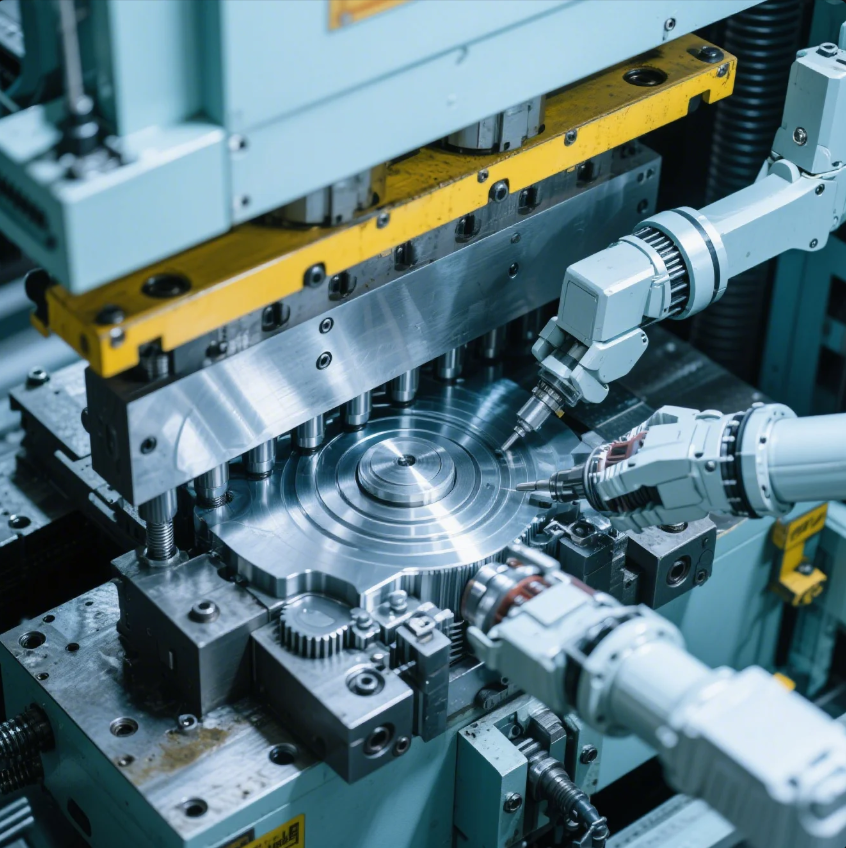

Automation improves precision

Modern stamping lines use robotic arms, vision systems, and real-time sensors. At Prime, we integrate servo-driven feeders and auto-ejectors to keep the process fast and safe. For a client in Germany, this meant cutting cycle times by 28% on a 200,000-unit bumper bracket order.

LOOP_END

LOOP_START

What is the manufacturing process of stamping cars?

Inconsistent part dimensions can ruin assembly line alignment.

Stamping in car manufacturing transforms flat steel sheets into structural and aesthetic car parts using large mechanical presses.

Full process from coil to chassis

| Step | Description |

|---|---|

| Coil Feeding | Raw sheet coils are unrolled and fed into the stamping line |

| Forming | Dies shape panels such as hoods, doors, and roofs |

| Multi-stage Stamping | Complex parts go through several progressive dies |

| Inspection & QA | Each part is checked for burrs, wrinkles, and cracks |

| Delivery to Assembly | Approved parts are moved to welding and body assembly zones |

Where Prime fits in automotive stamping

We specialize in small to mid-sized precision parts like crash brackets, seat belt anchors, and engine bay supports. Our ISO-certified lines and flexible die systems allow for custom solutions with shorter tool changeover times. That means faster production for global OEMs needing quick adaptation.

LOOP_END

LOOP_START

What is automotive stamping?

Automotive stamping is often misunderstood as a simple pressing technique.

Automotive stamping is a high-speed, high-precision method for producing metal vehicle parts using matched die sets and automated presses.

Why it's essential in auto manufacturing

| Benefit | Automotive Stamping Result |

|---|---|

| Dimensional Precision | Ensures proper panel fit and seam alignment |

| High Strength-to-Weight | Enables use of ultra-high strength steel for safety and weight |

| Cost Efficiency | Low cost per part for high-volume production |

| Repeatability | Consistent quality across thousands or millions of units |

Custom stamping at scale

At Prime, we’ve supported Tier 1 and Tier 2 automotive suppliers for over two decades. With 10 automated production lines, we deliver large batches of custom stamped automotive parts with reliable lead times. For example, we helped a Middle East client with custom stamping of dashboard supports—delivered under 25 days, fully packed for sea freight.

LOOP_END

Conclusion

Car stamping is a structured, multi-step process critical for strong, precise, and scalable auto part production.

Looking to improve your automotive stamping supply chain? Contact Prime today for free expert consultation, fast quotes, and custom part development—we deliver high-precision stamped parts with fast turnaround and ISO-certified consistency.