What does it mean to stamp a car and why does it matter in automotive production?

Auto manufacturers struggle with inconsistent body panel quality and rising production costs.

Stamping a car means shaping flat metal sheets into precise automotive components using high-tonnage presses and custom dies.

Understanding how this works helps buyers source smarter and avoid costly errors.

LOOP_START

What is the process of stamping a car?

Without a structured process, stamping errors can lead to costly defects in car assembly.

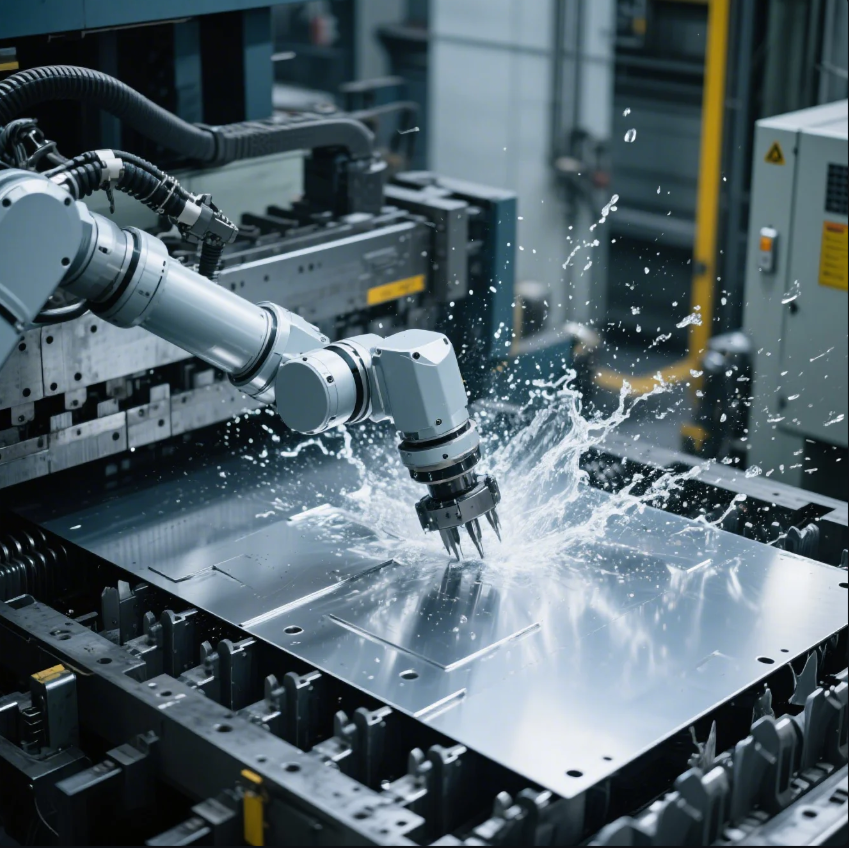

Stamping a car involves a step-by-step transformation of sheet metal into formed body panels and parts.

Main stages in the car stamping process

| Step | Function |

|---|---|

| Material Preparation | Sheet steel is uncoiled, leveled, and cut into blanks |

| Lubrication | Anti-friction coatings applied to reduce tool wear |

| Forming | Mechanical press shapes the metal using a die |

| Trimming | Extra material is removed for clean edges |

| Piercing & Notching | Holes and slots are created for later assembly |

| Flanging & Hemming | Edges are bent or folded to strengthen and prepare for joining |

How Prime supports the process

At Prime, we operate 10 automated stamping lines with progressive die technology. This allows us to combine several steps into one cycle. For our Australian client producing electric vehicle battery cases, we delivered over 300,000 units with ±0.02mm precision—on time and within budget.

LOOP_END

LOOP_START

What is stamping in automotive?

Some think stamping is limited to exterior panels, but it’s used much more widely.

Automotive stamping is a forming process that shapes steel or aluminum sheets into car body and internal structural components.

Parts typically made through stamping

| Component | Example Use |

|---|---|

| Outer Body Panels | Doors, hoods, fenders, trunk lids |

| Structural Parts | Reinforcements, brackets, seat mounts |

| Interior Metal Parts | Dash supports, door impact beams |

| Powertrain Supports | Battery trays, motor mounting brackets |

Why automotive stamping is critical

Stamping ensures repeatable accuracy. When tolerances are off, parts don’t fit on the assembly line—causing downtime and waste. At Prime, we meet ISO standards and use quality-inspected dies to avoid misalignments and cracks. For a Middle East auto plant, we helped reduce their rejection rate by 42% in six months.

LOOP_END

LOOP_START

What does stamps mean on a car?

“Stamps” on a car can refer to more than just formed parts—they also mean traceability and manufacturing origin.

In automotive terms, "stamps" often refer to identification marks left during the stamping process, showing part origin or compliance.

Two meanings of “stamps” on cars

| Type | Description |

|---|---|

| Physical Stamping Marks | ID numbers, tool references, batch codes embossed into parts |

| Manufacturing Stamping | The actual metal forming process that creates car components |

Why this matters for buyers and inspectors

Stamped markings are key for traceability and warranty claims. We support OEM traceability by including customized embossed codes on each batch, which helps with logistics and quality assurance audits. This level of detail can prevent supply chain confusion or dispute during product recalls.

LOOP_END

LOOP_START

What does the stamping process do?

Some assume stamping is just bending metal—but it does much more.

Stamping forms, strengthens, and prepares metal parts for welding, painting, or final assembly in automotive production.

Benefits of the stamping process

| Advantage | Impact on Automotive Production |

|---|---|

| High Speed | Enables mass production of parts with consistent accuracy |

| Design Flexibility | Complex shapes and contours are possible with custom dies |

| Structural Strength | Adds ridges and bends that enhance durability |

| Cost Efficiency | Low per-part cost for high-volume runs |

Our stamping process in action

Using servo-driven presses and robotic feeders, we can stamp thousands of parts per hour. For instance, in a North American project, we helped a client achieve 98.7% part accuracy across a 500,000-piece order for crash zone reinforcements.

LOOP_END

Conclusion

Car stamping transforms flat steel into precise, functional parts that define strength, safety, and style in vehicles.

Looking for a trusted partner in automotive stamping? Reach out to Prime now for a free consultation, tailored quote, and high-volume production backed by ISO-certified quality and rapid lead times. We help you build better, faster, and smarter.