Why is stamping used and what makes it essential in manufacturing?

Manufacturers often struggle to meet high-volume demands without losing precision or driving up costs.

Stamping is used to shape metal sheets into complex parts quickly, accurately, and at scale.

Let’s explore the reasons why stamping remains the go-to solution across industries.

LOOP_START

Why is stamping important?

Without stamping, manufacturers would face slow production and inconsistent quality in metal parts.

Stamping is important because it allows fast, repeatable production of high-precision metal components.

Core benefits of stamping

| Benefit | Result |

|---|---|

| Speed | High output with short cycle times |

| Accuracy | Tolerances as tight as ±0.01 mm |

| Scalability | Ideal for medium to high-volume production |

| Versatility | Supports a wide range of part shapes and sizes |

| Cost-Efficiency | Lower unit cost compared to machining or welding for large volumes |

How Prime delivers value with stamping

At Prime, we combine progressive die technology with automated feeding systems to produce large orders fast. For a client in North America, we delivered over 500,000 electrical enclosures with uniform precision in just 26 days.

LOOP_END

LOOP_START

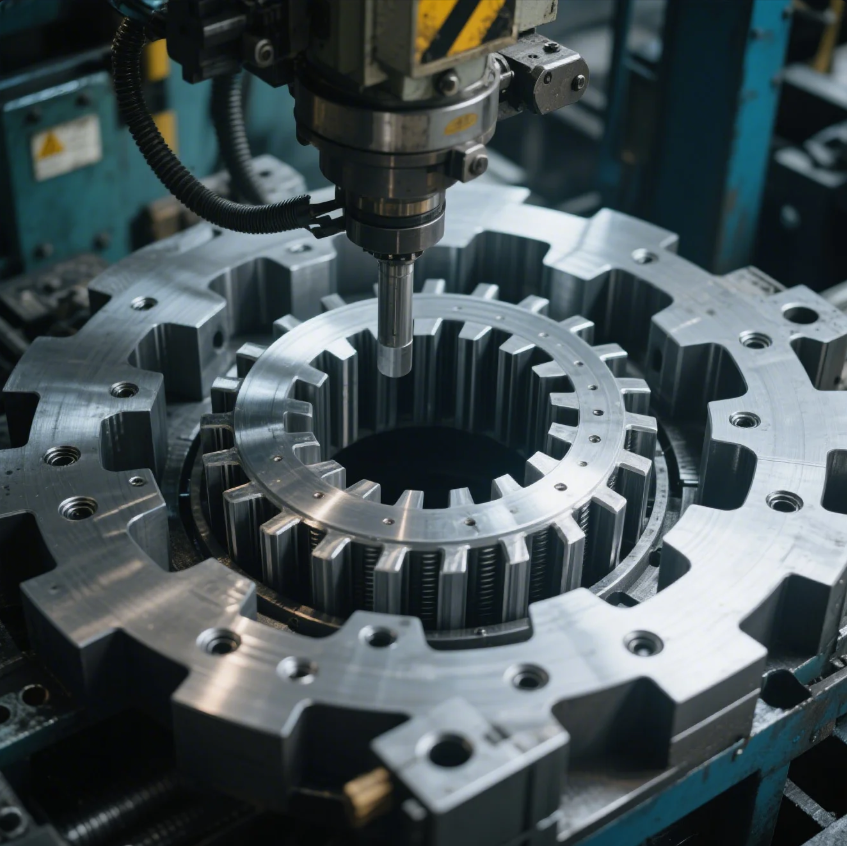

What is stamping used for?

Some buyers think stamping is only for automotive panels—but it's much broader.

Stamping is used to manufacture structural, decorative, and electrical parts in a wide range of industries.

Application examples by industry

| Industry | Stamped Products Examples |

|---|---|

| Automotive | Door panels, brackets, seat frames, engine covers |

| Electronics | Battery contacts, EMI shields, connector housings |

| Appliances | Mounting plates, panel frames, control interfaces |

| Industrial Equipment | Motor housings, gear brackets, base plates |

Our product range at Prime

We supply custom stamped parts in carbon steel, stainless steel, aluminum, and copper. Whether you're sourcing CNC-precision fasteners, ISO-certified brackets, or high-strength stamped assemblies, our 10 stamping lines ensure reliable quality and lead time.

LOOP_END

LOOP_START

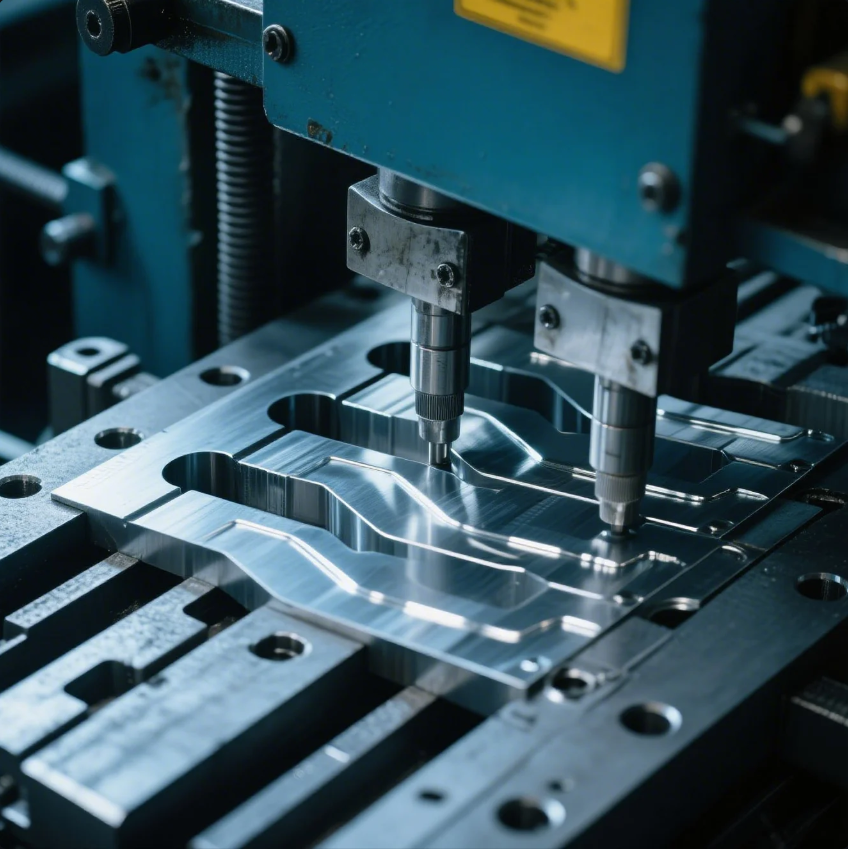

What is the concept of stamping?

Stamping isn’t just shaping—it’s a design strategy to simplify and accelerate manufacturing.

Stamping is the process of converting sheet metal into finished parts using dies, presses, and repeatable forming actions.

The concept simplified

| Stage | Purpose |

|---|---|

| Die Design | Custom tooling defines the final part shape |

| Material Selection | Choose sheet metal based on strength, flexibility, and conductivity |

| Forming Process | Apply force to shape or cut the metal sheet |

| Post-Processing | Deburring, coating, or assembly steps |

Prime’s design-first approach

We assist clients from the early stage with Design for Stamping (DFS) guidance. For a German electronics firm, we re-engineered their enclosure design to reduce weld points by 60%—replacing them with interlocking stamped features, improving both speed and structural strength.

LOOP_END

LOOP_START

What is stamped used for?

Stamped parts are found in almost every device or machine around you.

Stamped components are used in products ranging from vehicles and appliances to electronics and infrastructure.

Stamped parts in real life

| Product Type | Stamped Component Examples |

|---|---|

| Vehicles | Roof reinforcements, crash brackets, battery trays |

| Appliances | Oven hinges, fridge panels, washing machine supports |

| Consumer Electronics | Laptop shields, mobile battery terminals, USB connectors |

| Construction | Fasteners, support brackets, base plates |

Our role in global supply chains

We export to clients in Europe, North America, the Middle East, and beyond. Whether you need mass-produced stamped fasteners or precision CNC add-ons, Prime offers free consultations, competitive pricing, and rapid tooling turnaround backed by ISO standards.

LOOP_END

Conclusion

Stamping is fast, accurate, and cost-effective—ideal for making durable metal parts in high volumes across industries.

Need custom metal parts that balance quality and speed? Contact Prime today for a free consultation, quick quotes, and reliable stamping solutions—trusted worldwide for consistent, ISO-certified performance.