TEMPLATE_START

What is the effect of stamping and how does it improve manufacturing outcomes?

Manufacturers constantly seek faster, cheaper, and more reliable ways to produce metal components.

Stamping improves production speed, consistency, and cost-efficiency by transforming sheet metal into precise parts at scale.

Let’s explore the full impact of stamping on modern manufacturing and product performance.

LOOP_START

What is the importance of stamping?

Without stamping, producing large volumes of metal parts with consistent quality would be extremely slow and costly.

Stamping is important because it enables mass production of accurate and reliable metal components across industries.

Why stamping matters in global supply chains

| Benefit | Effect on Manufacturing |

|---|---|

| Repeatability | Ensures each part is identical to design specs |

| Time Efficiency | Short cycle times improve delivery speed |

| Reduced Labor Cost | Automation minimizes manual handling |

| Application Versatility | Suitable for automotive, electronics, appliances, and more |

Prime’s impact with stamping

At Prime, we’ve helped clients cut assembly time by delivering parts that require no post-processing. For example, our pre-flanged stamped panels for a U.S. HVAC firm reduced welding time by 40% and increased product lifespan.

LOOP_END

LOOP_START

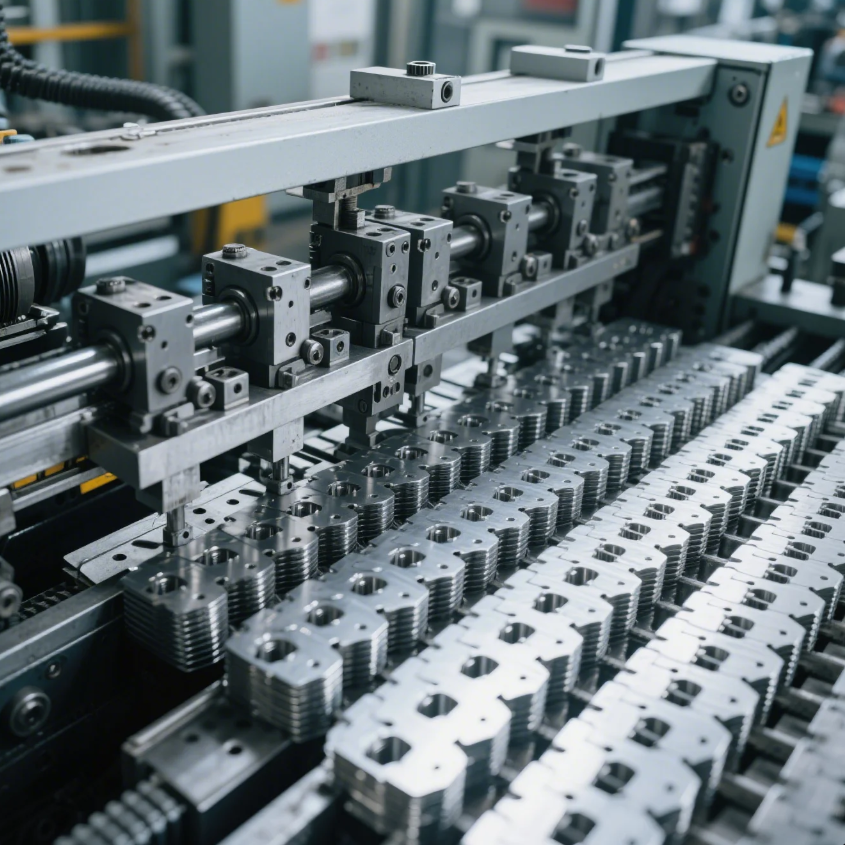

What are the advantages of stamping?

Many metalworking processes are slow, expensive, and inconsistent—stamping solves all three.

Stamping offers speed, low per-unit cost, tight tolerances, and minimal material waste—ideal for high-volume production.

Key advantages of stamping

| Advantage | Outcome |

|---|---|

| High Precision | Tolerances up to ±0.01 mm |

| Fast Production | Thousands of parts per hour with automated lines |

| Material Efficiency | Optimized layouts reduce scrap |

| Cost-Effective Tooling | Higher upfront cost but lower unit cost at scale |

What we deliver at Prime

Our 10 stamping lines are built for bulk runs with short lead times. Using progressive dies, we produce complex metal forms with multiple operations in one press cycle. This speeds up manufacturing and lowers labor costs for global clients.

LOOP_END

LOOP_START

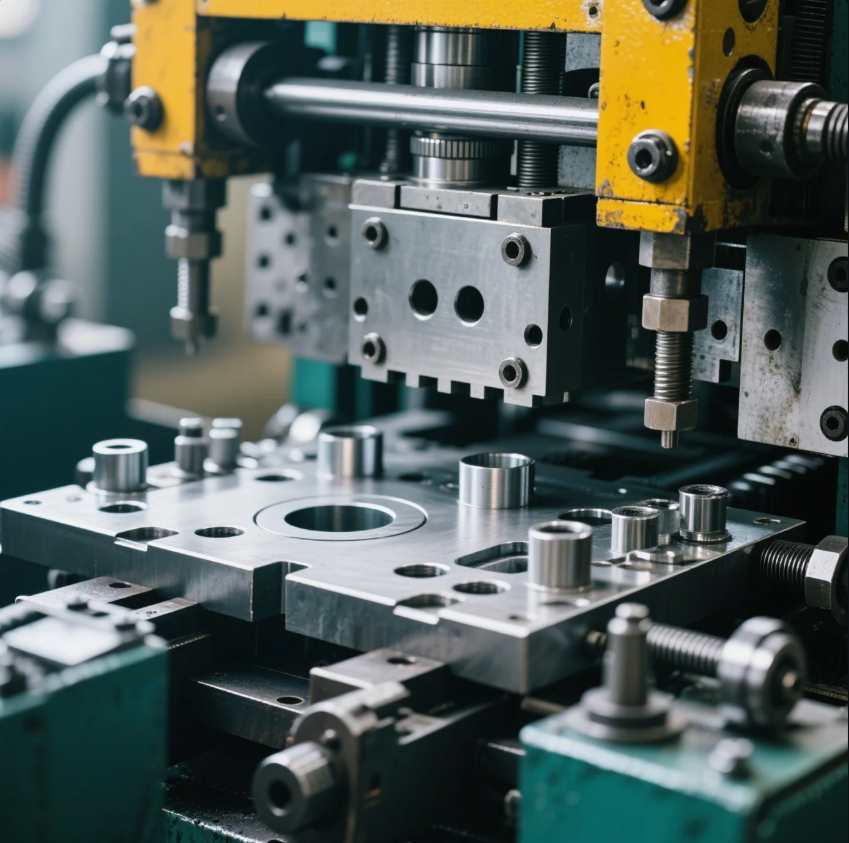

What is the concept of stamping?

Stamping is often misunderstood as just cutting metal—but it’s far more strategic.

The concept of stamping is using shaped dies and press machines to form flat sheet metal into complex, functional parts.

What stamping involves

| Element | Role in Stamping Process |

|---|---|

| Die Design | Defines the final part geometry |

| Sheet Metal | Provides raw material in coil or blank form |

| Press System | Applies controlled force to form, punch, or trim the part |

| Post-Processing | Includes deburring, coating, and part inspection |

How we use this concept at Prime

We design for efficiency. With in-house tooling, we customize dies for every project—whether it’s aluminum motor laminations or carbon steel fasteners. This allows rapid setup, less waste, and consistent quality in every order.

LOOP_END

LOOP_START

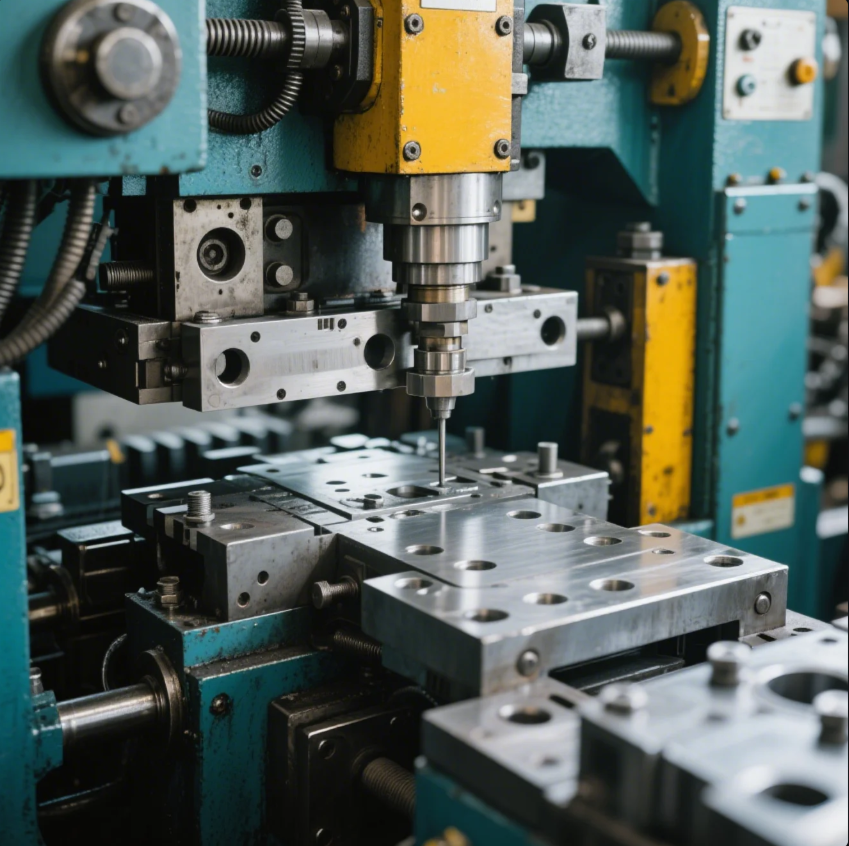

What does stamping do?

Stamping is not just one process—it’s a combination of forming, cutting, and shaping in one streamlined motion.

Stamping creates parts by cutting, forming, or embossing metal sheets using matched dies under controlled pressure.

What stamping achieves in production

| Function | Practical Outcome |

|---|---|

| Shaping | Transforms flat sheets into useful 3D forms |

| Cutting | Removes excess or unwanted material cleanly |

| Piercing | Adds holes, slots, or windows to parts |

| Flanging | Bends edges to prepare for joining or strengthen structure |

Our real-world results

Prime’s stamping expertise ensures that each part matches spec every time. For one European client in industrial electronics, we produced over 300,000 shield plates with no secondary processing needed—saving them thousands in labor and time.

LOOP_END

结论

Stamping speeds up production, lowers costs, and delivers precise metal parts—making it a foundational process in modern manufacturing.

Looking to scale production with efficient, ISO-certified stamping solutions? Contact Prime now for a free consultation, custom quote, and fast delivery—your trusted B2B partner since 1993.

TEMPLATE_END