Does hammering metal make it stronger and how does it affect the material?

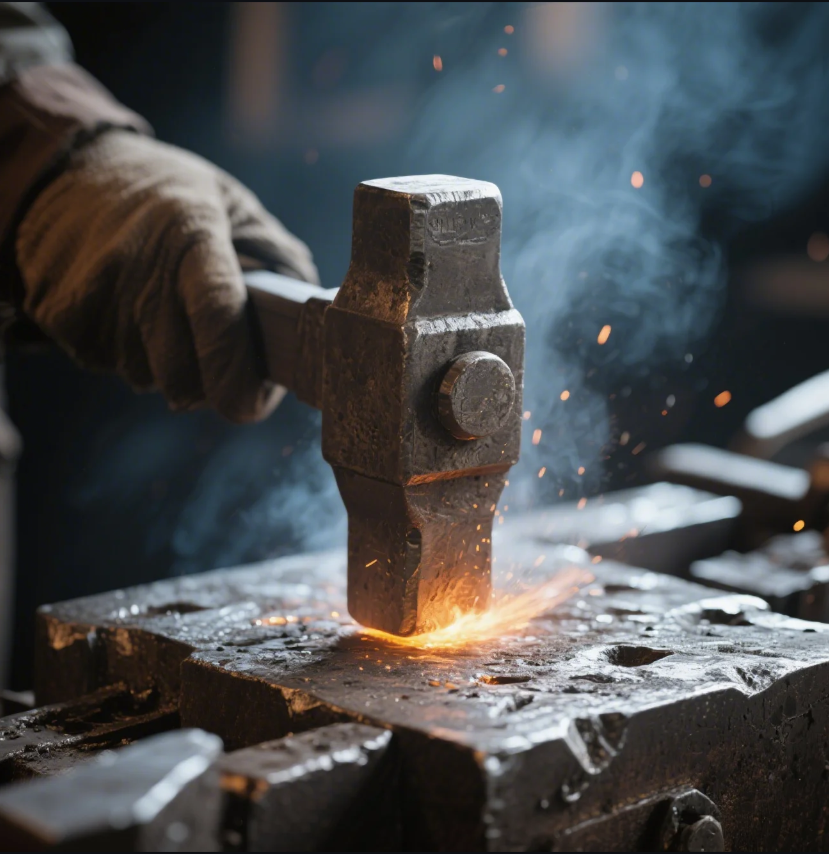

Many believe hammering just shapes metal—but it actually changes its internal structure too.

Yes, hammering metal can make it stronger through a process called work hardening, which increases density and resistance to deformation.

Let’s dive into how this works and when it’s beneficial—or risky.

LOOP_START

Does hammering metal make it harder?

Repeated hammering doesn't just change shape—it increases resistance too.

Yes, hammering metal causes work hardening, which makes it harder and less ductile.

Why hammering increases hardness

| Factor | Effect on Metal |

|---|---|

| Grain Structure Change | Compresses and aligns grains, increasing strength |

| Dislocation Density | Makes it harder for atoms to move—boosting surface hardness |

| Cold Work Effect | Occurs without heat, raising yield strength |

How we use this at Prime

For some projects, like forged fasteners or brackets, we apply controlled hammering or pressing to increase wear resistance without heat treating. For example, our cold-forged anchor pins passed 150,000-cycle fatigue tests with no visible wear.

LOOP_END

LOOP_START

How do you make a metal stronger?

Not all strength comes from size—it's about how you treat the metal.

To make metal stronger, you can use alloying, heat treatment, cold working (hammering), or surface hardening.

Strengthening techniques

| Method | How It Works | Ideal For |

|---|---|---|

| Alloying | Mixes metals to enhance properties (e.g., steel + chromium) | General durability |

| Heat Treatment | Alters microstructure (e.g., quenching + tempering) | Tools, springs, structural parts |

| Cold Working | Deforms metal at room temp, increases dislocation density | Fasteners, clamps, flat parts |

| Surface Hardening | Hardens outer layer via flame, nitriding, or induction | Gears, shafts, wear surfaces |

Prime’s engineering approach

We select the right combination based on the client’s needs. One North American client needed high-strength forged bolts—we cold-forged and heat-treated them, achieving 2.5x the tensile strength of standard steel.

LOOP_END

LOOP_START

What does hammering metal do?

It’s more than just shaping—hammering transforms the internal behavior of the metal.

Hammering metal compresses and strengthens it through a process known as plastic deformation or work hardening.

Effects of hammering

| Physical Result | Explanation |

|---|---|

| Shape Change | Reforms metal into desired geometry |

| Grain Refinement | Aligns grain flow, especially in forging |

| Increased Strength | Reduces ductility but improves hardness and resistance |

| Residual Stress | May introduce internal tension if not relieved by annealing |

Why we use hammering at Prime

We use controlled hammering or press forming during forging to pre-harden and pre-shape critical parts. Our forged coupler joints, used in offshore equipment, showed 38% greater wear resistance after hammer-based pre-compaction steps.

LOOP_END

LOOP_START

Does metal get stronger when you hit it?

Yes—but only to a point, and not without trade-offs.

Metal gets stronger when you hit it due to strain hardening, but excessive hammering can lead to brittleness or cracking.

Striking metal: benefits vs risks

| Action | Outcome |

|---|---|

| Moderate Hammering | Improves strength and hardness |

| Over-Hammering | Can cause cracks or grain boundary failure |

| Annealing (optional) | Restores ductility after excessive work hardening |

Balanced forging at Prime

We manage hitting force and temperature carefully. For precision automotive parts, we hammer to pre-strengthen, then anneal for stress relief. This balance allows for repeatable strength without fatigue failure, even under high load.

LOOP_END

Conclusion

Yes, hammering strengthens metal by refining grain structure and increasing hardness—but controlled technique is key to avoid brittleness.

Looking for forged parts with built-in strength and precision? Contact Prime now for a free consultation, custom forming services, and ISO-certified forging with superior material control—delivered globally.