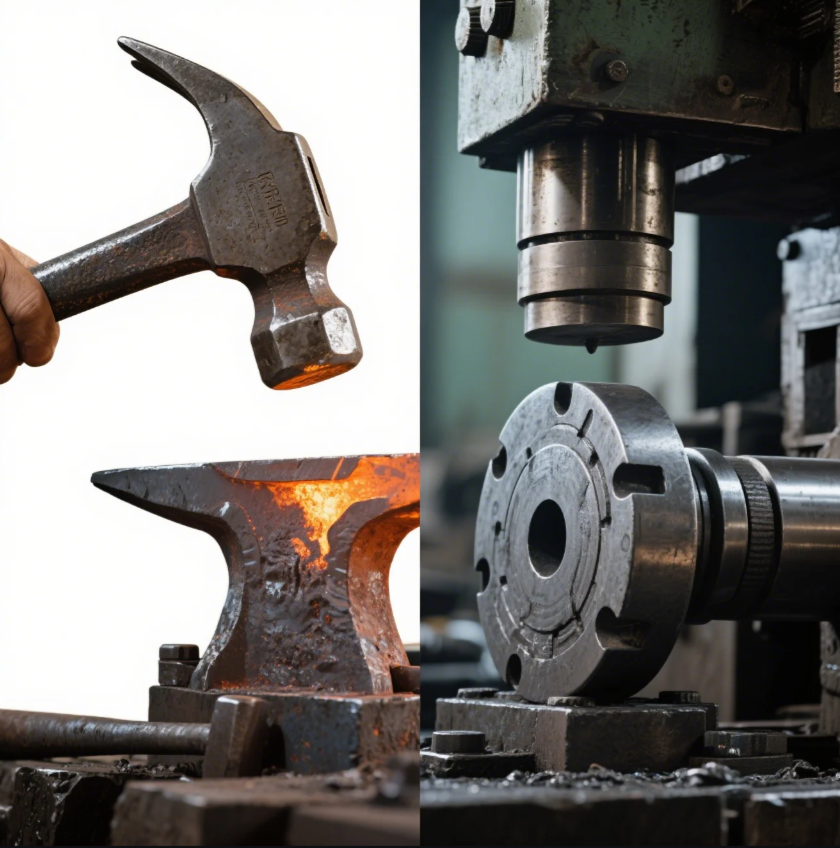

Is hammer forging better than press forging?

Forging buyers often feel stuck choosing between hammer forging and press forging—each has pros and tradeoffs.

Hammer forging uses impact blows; press forging uses steady pressure. Your choice depends on precision, volume, and material type.

Don’t just follow tradition—understand how each method fits your product needs and quality expectations.

LOOP_START

Why is press forging preferred over hammer forging process?

Hammer forging seems traditional, but many manufacturers are shifting to press forging for better results.

Press forging is often preferred for its precision, reduced defects, and better metal flow control.

Press Forging Advantages Explained

When I began sourcing ISO-certified forged parts for aerospace clients, I saw how press forging delivered fewer internal defects and better grain structure control. The slow, controlled compression shapes metal deeply and uniformly.

Hammer vs. Press Forging

| Feature | Hammer Forging | Press Forging |

|---|---|---|

| Action Type | Repeated impact | Steady pressure |

| Speed | Faster, manual control | Slower, automated |

| Grain Flow Control | Less consistent | More uniform |

| Surface Finish | Rougher | Smoother |

| Defect Rate | Higher (cracks, folds) | Lower |

For clients ordering custom forged components for machinery, we often recommend press forging. It’s ideal for high-volume, close-tolerance parts where consistency is key.

LOOP_END

LOOP_START

What is the difference between hammer forged and drop forged?

Buyers often confuse these two terms—they sound similar but serve different purposes.

Hammer forging is a manual or powered process using strikes. Drop forging uses gravity-powered dies for high-volume parts.

Don’t Let the Names Confuse You

I used to think “drop forging” just meant dropping a hammer. In truth, it's a controlled process using a closed die and high-precision equipment—something we use often at Prime for OEM casting and forging components.

Process Differences

| Forging Type | Description | Best Use Case |

|---|---|---|

| Hammer Forging | Manual or pneumatic hammering | Low-volume, artisan or prototype work |

| Drop Forging | Closed die dropped from height or pressure | High-volume, uniform industrial parts |

At Prime, we use drop forging for CNC-compatible forged blanks, where uniformity and structure are crucial for later machining steps.

LOOP_END

LOOP_START

Is drop forging the most accurate form of forging?

Many buyers assume drop forging is flawless—but it's not the only high-precision option.

Drop forging offers high accuracy for complex shapes, but closed-die press forging may be even more precise.

Accuracy Depends on Process Control

I’ve overseen many custom forged part production runs, and I’ve found that while drop forging offers repeatable results, the most dimensionally accurate results often come from press forging with CNC-trimmed dies.

Forging Accuracy Comparison

| Forging Method | Dimensional Accuracy | Volume Suitability | Tooling Cost |

|---|---|---|---|

| Open-Die Forging | Low | Low | Low |

| Hammer Forging | Medium | Low–Medium | Low–Medium |

| Drop Forging | High | Medium–High | Medium |

| Press Forging | Very High | Medium–High | High |

Prime uses a mix of drop and press forging based on part complexity. For precision fasteners and plastic-metal hybrids, we typically recommend press forging for best tolerance control.

LOOP_END

LOOP_START

What is the strongest forging press?

Some industrial buyers want maximum strength. But “strongest” isn’t always the most efficient.

Hydraulic forging presses with 50,000+ tons capacity are the strongest, used in aerospace and nuclear industries.

Force vs. Function

I’ve toured facilities with giant forging presses—some taller than buildings. But they’re not for everyone. For custom industrial hardware like we produce at Prime, 1,000–5,000 ton presses are more than enough for 90% of orders.

Top Presses by Type

| Press Type | Max Force | Best Use Case |

|---|---|---|

| Mechanical | Up to 12,000 tons | Simple, repetitive forging |

| Hydraulic | 50,000+ tons | Aerospace, shipbuilding, power |

| Screw/Servo | Up to 3,000 tons | Precise, smaller complex parts |

Unless you’re forging turbine shafts, go for efficiency and consistency, not just brute force. At Prime, our 3,000-ton hydraulic press handles custom metal casting parts with superior control and finish.

LOOP_END

Conclusion

Press forging offers better control, while drop forging gives repeatable precision. Choose based on your volume and tolerance needs.

Need help picking the right forging method for your parts? Contact Prime today. We provide expert guidance, rapid quotes, and ISO-certified forging and casting services for global clients. Whether you need durability, precision, or both—we deliver fast and reliably, every time.