What is the Purpose of Sealing?

Seal failure can cause equipment damage and production loss.

Sealing prevents leakage, contamination, and damage in industrial systems by creating a secure barrier.

Without proper sealing, systems break down faster and cause higher costs.

What is the Use of Sealing?

Seal problems can lead to unexpected shutdowns.

Sealing maintains system integrity by controlling leaks and keeping contaminants out.

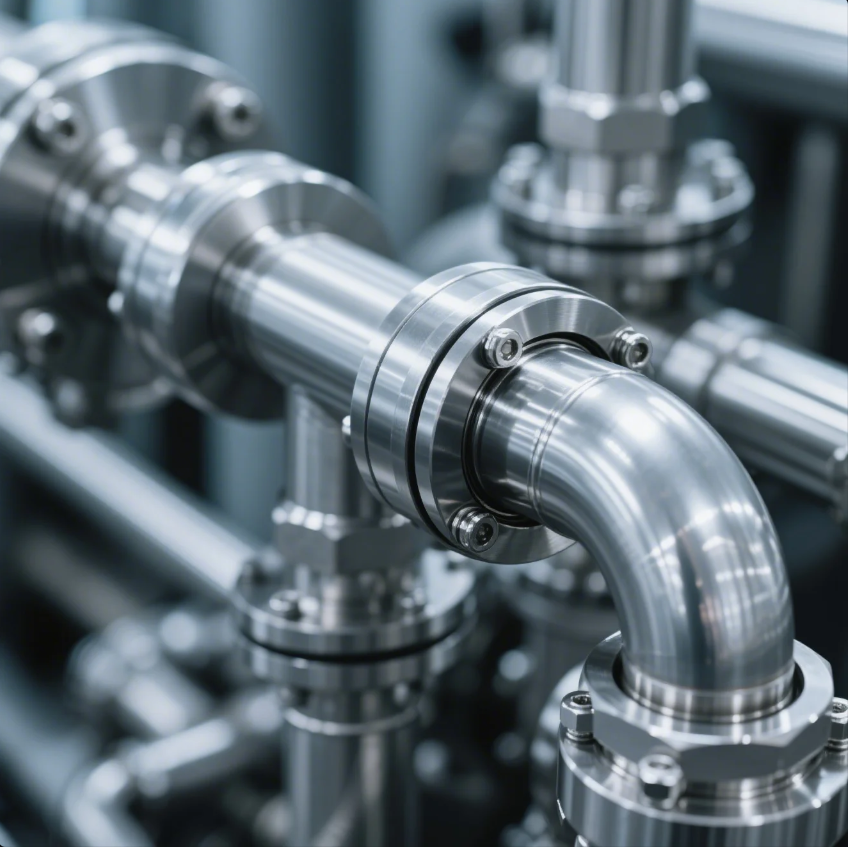

Why Sealing Matters in Industrial Applications

In industries like automotive, aerospace, and manufacturing, even the smallest leak can create serious problems. Sealing protects systems from dust, moisture, and chemical damage. Good seals mean longer machine life and fewer repairs.

How to Choose the Right Sealing Solution

Choosing the wrong seal can be very costly. Here are important factors to consider:

| Factors | Why They Matter |

|---|---|

| Material | Needs to resist chemicals and heat |

| Size and Fit | Must match equipment precisely |

| Pressure Resistance | Prevents leaks under high pressure |

| Certification | Proves quality and reliability |

At Prime, we supply sealing-related parts like CNC precision parts, stamping parts, and fasteners. We use only ISO-certified materials and processes to meet strict industrial standards.

What is the Function of Sealing?

Small leaks often cause major equipment failures.

The function of sealing is to block, retain, and protect critical areas from leakage and external attack.

Main Functions of Industrial Sealing

Seals do more than stop leaks. They also:

- Protect against dust and debris

- Maintain pressure levels

- Prevent fluid contamination

- Improve equipment safety

- Extend service life

Real-World Examples: Where Sealing is Critical

In hydraulic systems, faulty seals mean lower efficiency and higher repair bills. In electronics, poor sealing can lead to moisture damage and short circuits. Proper sealing ensures that systems work reliably, even in extreme conditions.

| Industry | Common Sealing Needs |

|---|---|

| Automotive | Fluid system sealing |

| Aerospace | High-pressure environment |

| Manufacturing | Dust and chemical protection |

Prime’s custom CNC parts and ISO-certified casting parts are designed to meet the sealing requirements of tough industrial environments. We customize dimensions, materials, and finishes to fit your project perfectly.

What is the Purpose of a Sealant?

Leaks start small but grow bigger without the right sealant.

A sealant fills gaps and blocks passageways to prevent leaks, maintain pressure, and protect from damage.

How Sealants Support Industrial Systems

Sealants are different from mechanical seals. They are softer materials that fill spaces between parts. They make the whole system watertight, airtight, or chemically resistant.

Choosing the Right Sealant

When picking a sealant, you must think about:

| Considerations | Importance |

|---|---|

| Chemical Compatibility | To resist breakdown by chemicals |

| Temperature Range | Must survive operating conditions |

| Flexibility | To allow slight movements |

| Application Method | Spraying, brushing, or injecting |

Our plastic parts and fasteners often work together with industrial sealants to create a double-protection system. Prime offers full customization to fit your sealing projects, ensuring top quality and long service life.

What is the Purpose of Sealed?

Unsealed systems are exposed to serious risks.

Sealed systems ensure the internal environment stays controlled, protecting sensitive parts and extending service life.

Benefits of a Sealed System

Sealing is not just about blocking leaks. It also:

- Prevents contamination

- Reduces maintenance needs

- Increases reliability

- Enhances operational safety

- Protects against environmental attacks

Prime’s Role in Helping You Achieve Perfect Sealing

Prime has over 20 years of experience supplying custom stamping parts, precision CNC parts, and ISO-certified fasteners for sealing applications. Our products are built to fit tightly and perform under extreme conditions.

| Prime Advantage | What It Means for You |

|---|---|

| ISO-certified Quality | Consistent reliability |

| Custom Solutions | Tailored to your exact needs |

| Rapid Delivery | Projects stay on schedule |

| Professional Packaging | Protects parts during shipping |

Our one-stop service guarantees quality from design to delivery. No more worrying about poor communication, delayed shipments, or damaged goods.

Conclusion

Sealing protects systems, extends their life, and ensures operational success in every industrial project.

Contact Prime today for a free consultation, customized quote, and sealing solution recommendation. Our ISO-certified products, fast delivery, and strong communication guarantee a smooth experience and reliable results for your next project.