What Is a Sealing Process?

Leaks destroy equipment performance and reduce customer satisfaction.

The sealing process involves creating a secure barrier to prevent leakage, contamination, or pressure loss in mechanical systems.

This process protects sensitive parts and ensures long-term reliability.

What Is the Function of Sealing?

Loose connections cause fluid leaks, which result in costly downtime.

Sealing protects systems by preventing leaks, keeping out contaminants, and ensuring pressure consistency.

How Sealing Works in Industrial Applications

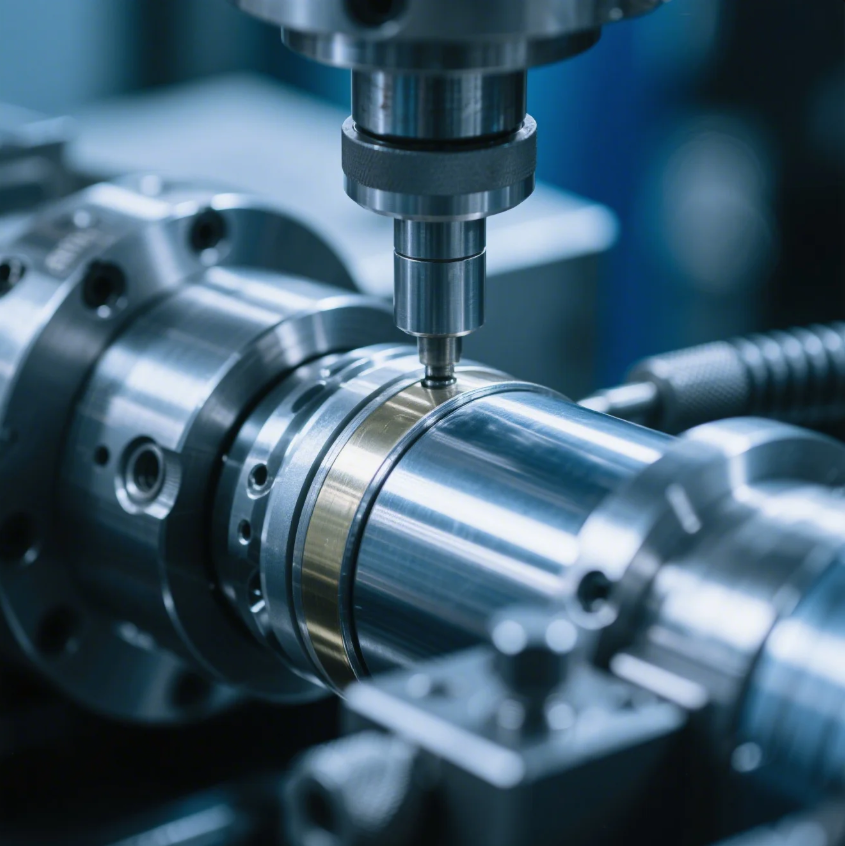

Sealing serves one primary function: to close gaps. These gaps might occur between two mating surfaces or around a moving part like a rotating shaft. The sealing process fills or covers those spaces to keep things in—or out.

Core Functions of a Sealing Process

| Function | Description |

|---|---|

| Leakage Prevention | Stops air, oil, water, or gas from escaping |

| Pressure Retention | Maintains pressure inside systems |

| Contamination Blocking | Keeps dust, moisture, and debris out |

| Vibration Isolation | Reduces system wear and noise |

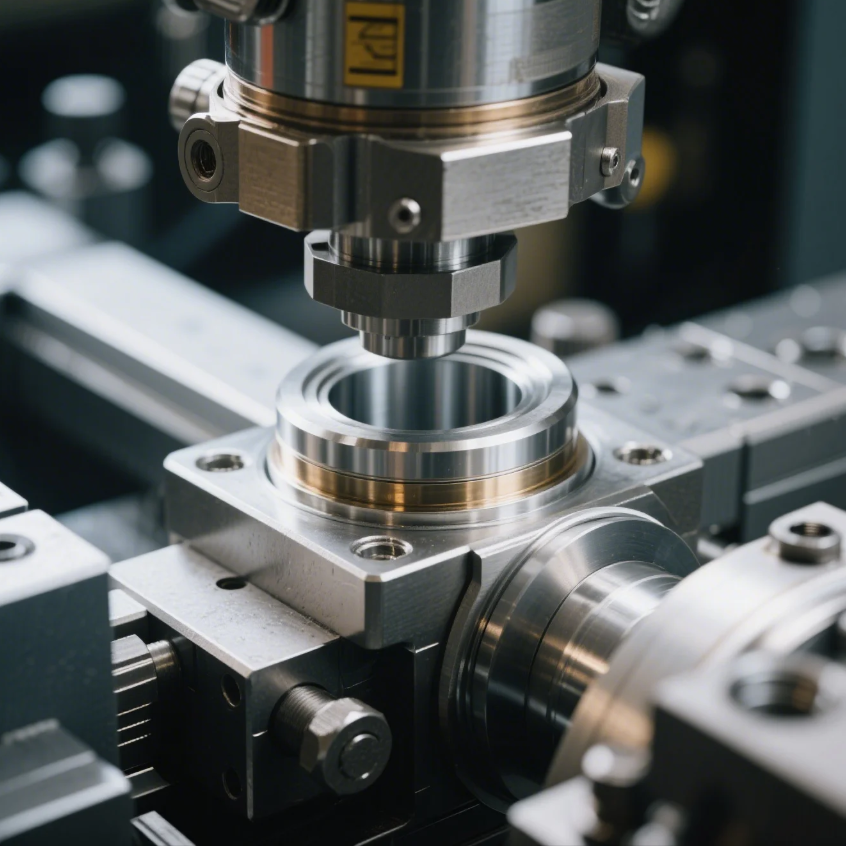

At Prime, we understand that high-performance sealing depends on precision. That’s why our ISO-certified casting parts, CNC-machined sealing rings, and custom fasteners are trusted by engineers worldwide.

What Is the Concept of Sealing?

Engineers struggle when system gaps compromise integrity.

Sealing is the act of securing mechanical interfaces to prevent unwanted flow or exposure.

Sealing as a Design Concept

From engines to pipelines, sealing is built into every engineering system. It is not an afterthought—it is part of the design. Every gap, joint, or interface must be assessed for risk of leakage or ingress.

Common Seal Designs in Industry

| Sealing Design | Where It’s Used |

|---|---|

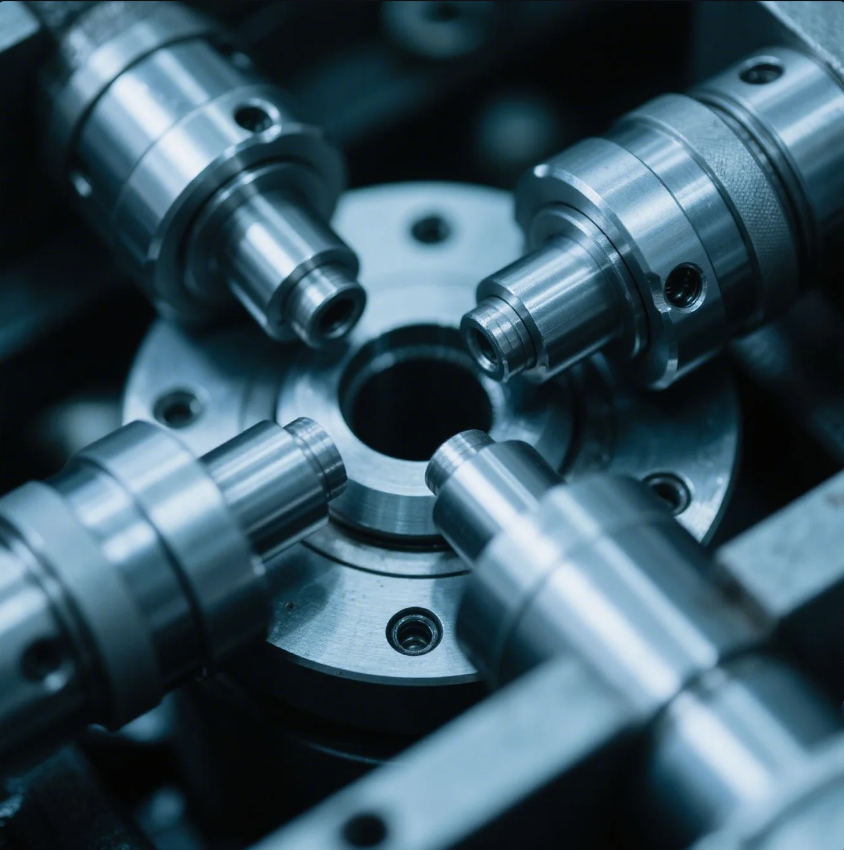

| Static Seals | Flange joints, valve covers |

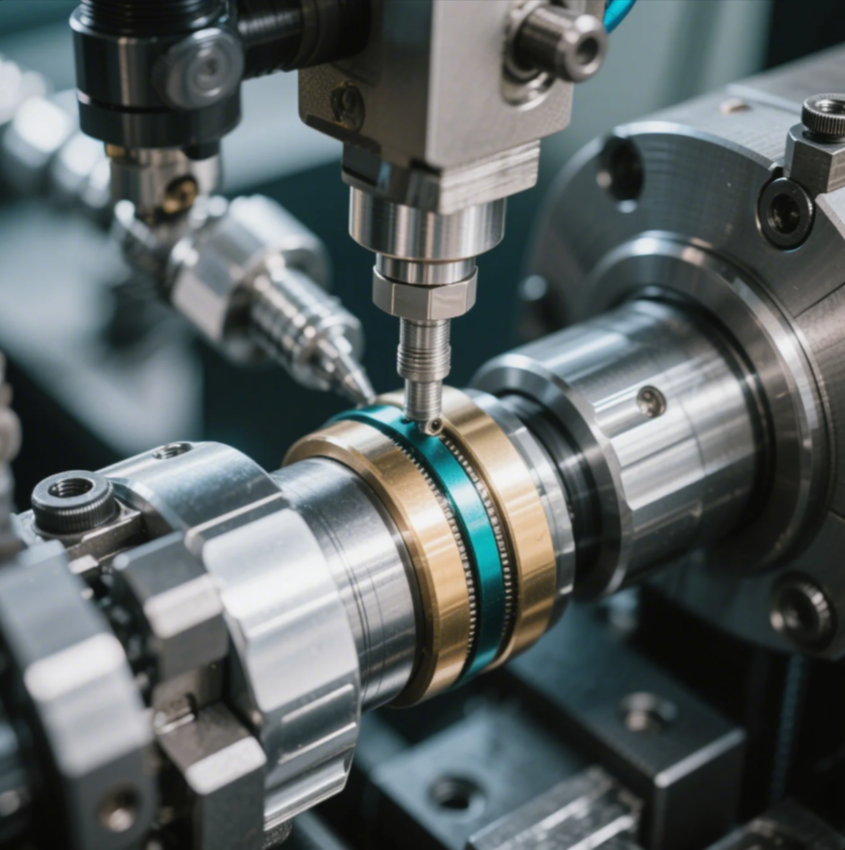

| Dynamic Seals | Shafts, pistons, pumps |

| Thermal Seals | Environments with heat cycling |

| Pressure Seals | Compressors, pressurized chambers |

Prime’s engineering team offers one-stop sealing solutions, from concept to delivery. With over 20 years in industrial hardware, we tailor CNC parts and precision plastics that work in high-load, high-pressure, or high-speed systems.

What Are Sealing Techniques?

Poor sealing technique leads to early system failure.

Sealing techniques are methods used to block gaps and ensure a tight, durable fit.

Different Techniques for Different Needs

Sealing is more than placing a rubber ring. Each industry has unique challenges—fluid type, temperature, pressure, and motion. Therefore, the sealing method must match those exact conditions.

Overview of Common Techniques

| Technique | How It Works |

|---|---|

| Gasket Sealing | Flat seal compressed between two surfaces |

| O-ring Sealing | Circular seal compressed into grooves |

| Mechanical Sealing | Faces pressed together by springs |

| Adhesive/Sealant Sealing | Liquid or gel applied and cured |

| Heat Sealing | Melting surfaces together (plastics) |

Prime specializes in precision-manufactured sealing parts. Our CNC-machined grooves, custom plastic rings, and welding components are all tailored to improve sealing performance in industrial machines.

What Are the Methods of Sealing?

Without the right method, even the best parts will fail.

Sealing methods vary by application and material type—each has a specific role in system integrity.

Choosing the Right Sealing Method

You must consider movement, temperature, chemical exposure, and pressure. Selecting the right sealing method is not guesswork—it’s engineering.

Comparative Table of Sealing Methods

| Sealing Method | Best For | Notes |

|---|---|---|

| Compression Gasket | Static, flat surfaces | Easy install, wide material range |

| Lip Seal | Rotary shafts | Good for moderate speed/pressure |

| Bellows Seal | High flexibility needs | Good for vibration or misalignment |

| O-Ring | Simple static or dynamic sealing | Cheap and versatile |

| Adhesive Sealant | Lightweight and complex geometries | Requires curing time |

Prime helps clients reduce sealing failure rates by supplying ISO-certified fasteners, custom CNC seal housings, and casting components built with exacting tolerances. Our parts support better assembly and long-term sealing reliability.

Conclusion

Sealing is a core process that ensures safety, performance, and reliability across all types of industrial systems.

Contact Prime now to get expert sealing component support. We offer customized solutions, ISO-compliant parts, and fast worldwide delivery. Trust our 20+ years of experience to improve your sealing performance and production uptime.