What is an example of a surface treatment?

The wrong surface finish leads to rust, wear, and lost business.

Anodizing is a popular surface treatment for aluminum. It improves hardness, corrosion resistance, and visual quality.

Surface treatments are more than just looks. They protect products and boost performance.

What are the surface treatments for metal?

Unprotected metal parts quickly rust or degrade. This shortens service life and increases costs.

Metal surface treatments include anodizing, electroplating, powder coating, passivation, and polishing. Each one solves specific problems.

The right treatment depends on the metal type and working environment.

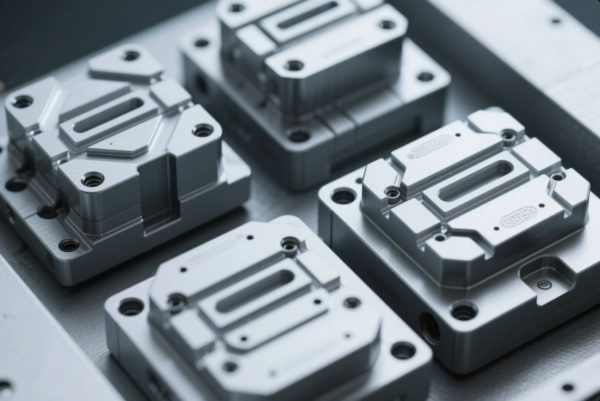

Top Surface Treatments for Industrial Metal Parts

| Treatment Type | Primary Benefit | Best Used For |

|---|---|---|

| Anodizing | Strengthens aluminum surfaces | CNC-machined aluminum parts |

| Electroplating | Enhances corrosion resistance | Screws, fasteners, connectors |

| Powder Coating | Durable and colorful finish | Metal enclosures, frames |

| Passivation | Prevents stainless steel corrosion | Valves, fittings, machined parts |

| Polishing | Improves surface smoothness | Visible or decorative components |

We at Prime offer all of these options. Whether you're sourcing custom stamping parts or ISO-certified CNC parts, we ensure the right treatment every time.

What are the methods of surface treatment?

Some treatments look similar but perform very differently. Knowing the method helps avoid mistakes.

There are five key surface treatment methods: mechanical, chemical, electrochemical, coating-based, and heat treatment.

Each method changes the surface in its own way—either by removing imperfections or adding a protective layer.

Common Surface Treatment Methods Explained

| Method | Example Process | Benefit |

|---|---|---|

| Mechanical | Polishing, blasting | Removes flaws, prepares surface |

| Chemical | Pickling, passivation | Cleans and protects surfaces |

| Electrochemical | Electroplating, anodizing | Adds protective layers using current |

| Coating-Based | Painting, powder coating | Decorative and weatherproof barrier |

| Heat Treatment | Annealing, hardening | Alters metal strength and structure |

As an experienced custom stamping parts supplier, we help customers select the best method for their project and budget.

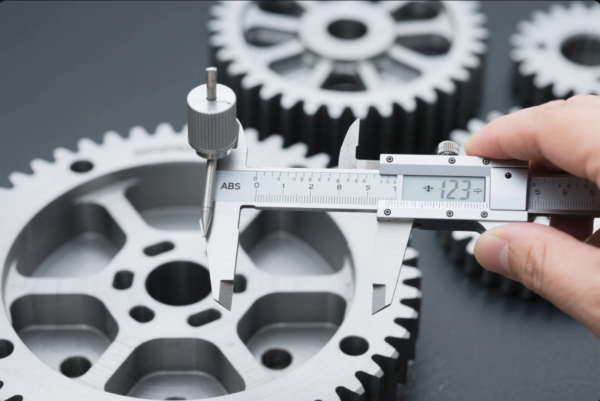

What are the different types of surface finishes?

Choosing the wrong surface finish increases wear and decreases product value.

Surface finishes vary from rough to highly polished. Common types include matte, satin, brushed, and mirror.

The finish affects friction, appearance, and how coatings stick to the surface.

Surface Finishes and Their Applications

| Finish Type | Surface Texture | Best For |

|---|---|---|

| Matte | Low gloss, uniform look | Hidden or internal parts |

| Satin | Soft shine, clean finish | Consumer products, control panels |

| Brushed | Visible linear marks | Decorative fasteners, faceplates |

| Mirror Polished | High gloss, flawless surface | Automotive trim, decorative CNC parts |

We finish our custom CNC parts and ISO-certified casting components with the texture you need—based on your functional and branding goals.

What are the three main categories of surface treatment?

Not all surface treatments are the same. Each category has a different purpose and process.

Surface treatments fall into three categories: mechanical, chemical, and coating. These groups define how the treatment works.

Understanding them helps buyers make smarter, cost-saving decisions.

The Three Main Surface Treatment Categories

| Category | Example Treatments | Application Purpose |

|---|---|---|

| Mechanical | Grinding, polishing | Surface prep, visual improvement |

| Chemical | Pickling, passivation | Cleaning and corrosion prevention |

| Coating | Powder coating, painting | Weather and wear protection |

At Prime, we use all three to deliver reliable, long-lasting finishes. Our team recommends the best one for your precision CNC parts or custom metal components.

Conclusion

Prime helps you choose the right surface treatment for better durability and appearance.

Contact Prime today for expert guidance, free consultation, and fast delivery. With over 20 years of experience, 10 production lines, and a global client base, we supply ISO-certified CNC parts, custom stamping parts, and durable surface finishes that match your business needs.