What is the most common basic corrosion inhibitor used on metal?

Metal corrodes when exposed to air, moisture, or chemicals—damaging performance and cutting service life.

Zinc is the most common corrosion inhibitor used on metal. It’s affordable, effective, and works with steel, iron, and other alloys.

Using zinc-based protection saves costs and prevents early product failure.

What is the most common corrosion inhibitor?

Corrosion reduces metal strength and leads to system breakdowns. A simple inhibitor prevents costly repairs.

Zinc is the most commonly used corrosion inhibitor. It’s applied through galvanizing or electroplating and forms a sacrificial barrier.

The zinc layer corrodes first, protecting the steel underneath.

Zinc Protection Methods

| Application Method | Common Usage Areas | Lifespan |

|---|---|---|

| Hot-Dip Galvanizing | Outdoor frames, fencing | 20–50 years |

| Electroplating (Zinc) | Screws, fasteners, CNC parts | 5–15 years |

| Cold Galvanizing Spray | On-site repairs | Short-term, maintenance required |

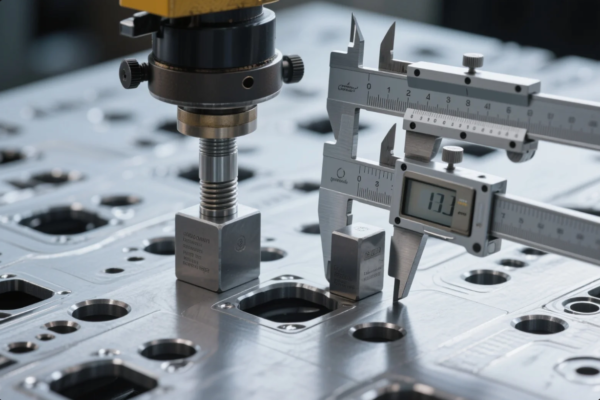

At Prime, we apply zinc coatings to our custom stamping parts and CNC components, ensuring long-lasting corrosion resistance.

What is the best corrosion inhibitor?

Some treatments offer short-term protection only. Others last for decades and require no maintenance.

The best corrosion inhibitor depends on the application. For outdoor use, hot-dip galvanizing is the strongest and most reliable option.

Other high-performance inhibitors include epoxy coatings and ceramic layers.

High-Performance Corrosion Inhibitors

| Inhibitor Type | Ideal Use Case | Key Benefit |

|---|---|---|

| Zinc (Hot-Dip) | Structural steel outdoors | Long-lasting, no maintenance |

| Epoxy Coating | Machines, tools | High chemical and abrasion resistance |

| Ceramic Coating | Exhausts, high-temp parts | Heat-resistant, extreme durability |

| Phosphate Conversion | Primer layer for painting | Improves paint bonding, adds rust delay |

We at Prime evaluate product exposure, shipping time, and part function to choose the best inhibitor. Our goal is to give your metal parts a longer life, even in harsh environments.

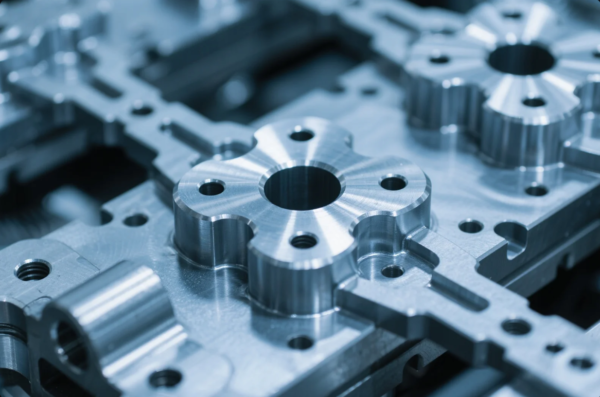

What are the corrosion inhibitors for steel?

Steel rusts faster than most metals. Without protection, it weakens and fails early.

Common corrosion inhibitors for steel include zinc coatings, oil films, phosphate treatments, and passivation. Each one creates a barrier against moisture and oxygen.

Some methods are temporary, while others are permanent.

Corrosion Protection Options for Steel

| Method | Duration | Used For |

|---|---|---|

| Zinc Electroplating | Medium-term | Screws, bolts, fittings |

| Oil Coating | Short-term | Stored parts or in-transit products |

| Phosphating | Medium-term | Paint prep, auto parts |

| Passivation (SS) | Long-term | Stainless steel components |

We provide rust-resistant finishes for all steel CNC parts and custom stamping components. Our team tailors the solution to your supply chain and use case.

What is the most durable anti-corrosion application on metal?

Durability matters for outdoor, marine, or long-term storage use. The wrong finish won’t last under pressure.

Hot-dip galvanizing is the most durable corrosion protection for steel. It forms a thick zinc layer that bonds with the base metal.

Other strong options include epoxy powder coating and ceramic layers.

Durability Ratings of Anti-Corrosion Applications

| Treatment | Durability Rating | Notes |

|---|---|---|

| Hot-Dip Galvanizing | ★★★★★ | Best for structural and outdoor steel |

| Epoxy Powder Coating | ★★★★☆ | Great for color and mechanical strength |

| Ceramic Coating | ★★★★☆ | High-temp resistance and durability |

| Zinc Spray | ★★☆☆☆ | Temporary or repair-focused |

At Prime, we recommend hot-dip galvanizing or powder coating for demanding jobs. Our ISO-certified parts hold up under pressure—indoors or outdoors.

Conclusion

Zinc remains the most common and cost-effective corrosion inhibitor for metals.

Contact Prime today to get expert help with corrosion protection. With over 20 years of experience, 10 production lines, and ISO-certified surface treatments, we provide durable, rust-resistant CNC parts, stamping components, and fasteners tailored to your needs.