Is there an undercoating that stops rust?

Road salt, moisture, and debris attack untreated metal—especially under vehicles.

Yes, undercoating products like rubberized sprays, wax-based coatings, and oil treatments stop rust by sealing out water and salt.

Choosing the right one depends on climate, usage, and budget.

Will undercoating stop rust?

Rust begins where metal is exposed. Undercarriages face the worst conditions.

Undercoting can stop rust if applied to clean, rust-free surfaces. It creates a physical barrier that blocks moisture and salt.

Some formulas also slow rust on already affected areas.

Rust-Stopping Undercoating Types

| Type | Rust Protection Level | Ideal Use |

|---|---|---|

| Rubberized Coating | High | Vehicle frames, underbodies |

| Wax-Based Undercoating | Moderate | Seasonal protection, quick drying |

| Oil-Based Coating | Medium | Hard-to-reach spots, internal panels |

At Prime, we use industrial-grade rust-proofing for custom metal parts during storage or transport—especially on parts shipped to wet or coastal regions.

What is better, rust proofing or undercoating?

Both methods protect metal—but serve different purposes.

Rust proofing is ideal for interior sections and tight cavities. Undercoating is better for outer surfaces exposed to physical damage.

Many use both for full protection.

Comparison: Rust Proofing vs. Undercoating

| Feature | Rust Proofing | Undercoating |

|---|---|---|

| Area Covered | Hidden areas, crevices | Frames, wheel wells, underbody |

| Application Method | Sprayed into cavities | Sprayed or brushed on open surfaces |

| Lifespan | 1–2 years | 2–5 years (with touch-ups) |

| Best Used For | Inside doors, seams | Bottom of cars, exposed steel |

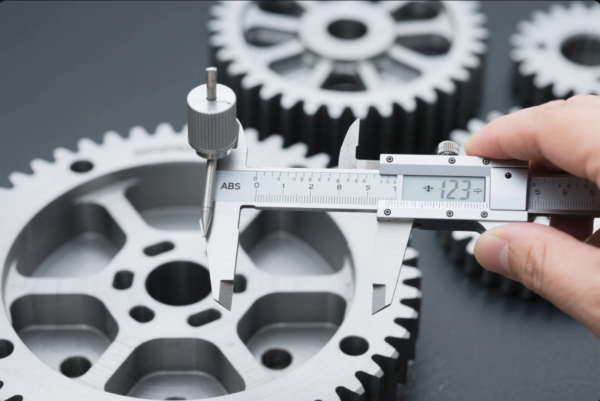

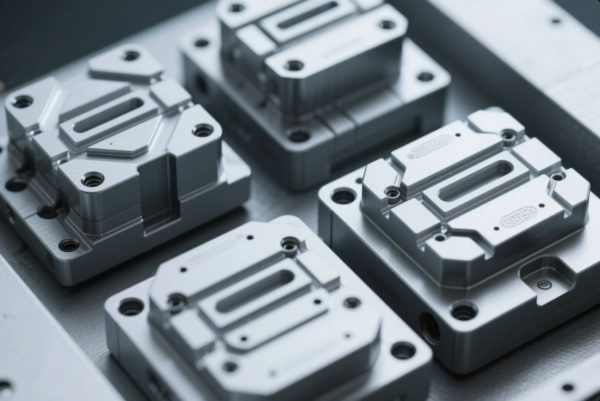

We offer sealed packaging and rust inhibitors for our stamped steel parts and CNC components, depending on client shipping needs.

How long does rust-proof undercoating last?

Buyers want durable protection—but coatings wear down over time.

Most undercoatings last 2 to 5 years. Some need touch-ups after winter or heavy road use.

Their lifespan depends on quality, environment, and prep work.

Undercoating Lifespan Guide

| Coating Type | Typical Lifespan | Maintenance Needs |

|---|---|---|

| Rubberized Coating | 3–5 years | Check annually, reapply if chipped |

| Wax-Based Coating | 1–2 years | Reapply after each winter |

| Oil-Based Coating | 6–12 months | Requires regular reapplication |

For long-term industrial applications, we recommend hot-dip galvanizing or powder coating—solutions we apply to Prime’s CNC and casting parts for lasting results.

What are the disadvantages of car undercoating?

Not all undercoatings are risk-free. Some can trap moisture or fail without prep.

Main drawbacks include poor adhesion to dirty surfaces, added weight, and potential trapping of rust beneath the coating.

That’s why cleaning and inspection are key.

Undercoating Drawbacks to Watch

| Disadvantage | Risk Level | How to Prevent |

|---|---|---|

| Traps moisture under rust | High | Only apply to clean, dry surfaces |

| Adds weight to vehicle | Low | Apply evenly, avoid thick layers |

| Peels if improperly applied | Medium | Prep surface and dry fully |

| Short lifespan for low-cost types | High | Use high-quality, branded coatings |

At Prime, we apply corrosion protection only to properly cleaned surfaces—ensuring our ISO-certified stamped and CNC parts arrive safe, clean, and rust-free.

Conclusion

Yes, quality undercoating stops rust—but only with proper prep and regular maintenance.

Contact Prime today for rust-proof metal parts, industrial coatings, and expert advice. With 20+ years of experience, 10 production lines, and ISO-certified protection, we deliver reliable, rust-resistant components tailored to global markets.