How to refinish a metal surface?

Old or damaged metal loses value and function without proper refinishing.

To refinish a metal surface, remove rust or paint, sand the surface, apply primer, then spray or brush on protective topcoats.

With the right tools and steps, even worn metal can look and perform like new.

How do I refinish metal?

Paint peeling, surface rust, or dull finishes make parts unsafe or unsightly.

You refinish metal by cleaning, sanding, priming, and repainting or recoating it. This restores both appearance and corrosion resistance.

Preparation is key for smooth, long-lasting results.

Basic Metal Refinishing Steps

- Clean the surface with degreaser or alcohol

- Remove rust/paint using sandpaper or a wire brush

- Sand evenly to roughen the surface for adhesion

- Apply primer for metal (zinc or epoxy-based)

- Topcoat with spray paint, enamel, or powder coating

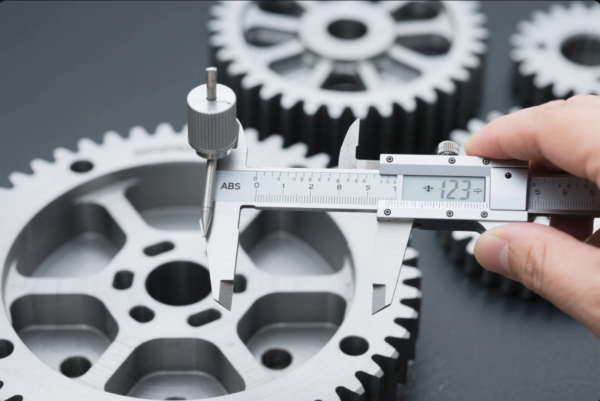

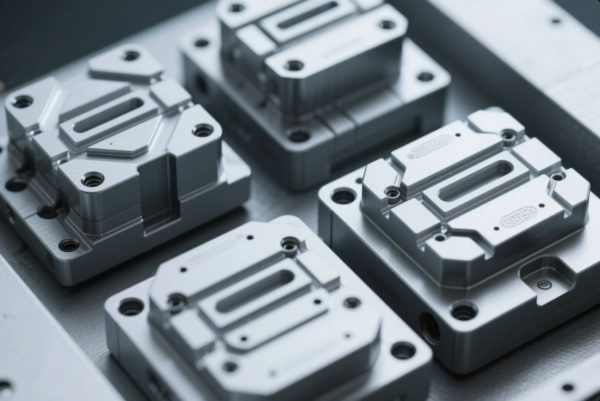

At Prime, we use these steps before applying ISO-certified coatings to our custom CNC parts and stamped steel components.

How do you restore metal surfaces?

Surface rust and wear damage metal over time—but most parts can be saved.

To restore metal, first remove rust or old finishes, then polish or fill the surface. Finally, recoat it with primer and protective finish.

The goal is to stop corrosion and bring back structural and visual integrity.

Metal Restoration Tools

| Tool/Material | Purpose |

|---|---|

| Wire brush | Removes rust and loose paint |

| Sandpaper (80–320) | Smooths and prepares surface |

| Rust converter | Neutralizes light oxidation |

| Filler or putty | Repairs dents and pitting |

| Primer and paint | Seals and finishes the surface |

At Prime, we restore damaged or returned parts before reshipping to ensure client-ready surface quality on all custom orders.

Is it better to spray or paint metal?

The finish quality depends on how the coating is applied.

Spraying offers smoother, more even coverage on metal. Brushing works well for small parts or touch-ups.

Spray finishes dry faster and reduce brush marks, especially on larger surfaces.

Spraying vs. Brushing Metal Coatings

| Method | Pros | Cons |

|---|---|---|

| Spray | Smooth, fast, even coverage | Needs masking and ventilation |

| Brush | Precise control, easy for detail | Brush marks, slower application |

At Prime, we rely on automated spray booths and powder coating lines to coat parts efficiently and consistently—ensuring your CNC components arrive with a flawless finish.

Should you sand between coats of paint on metal?

Skipping this step often causes poor adhesion or visible surface flaws.

Yes, lightly sanding between coats helps paint stick better and smooths out dust or imperfections.

Use fine-grit sandpaper (220–400) and clean the surface before recoating.

Sanding Between Coats: Best Practices

- ✅ Use 220–400 grit for mid-coat sanding

- ✅ Wipe with tack cloth after sanding

- ✅ Sand only after the coat is fully dry

- ✅ Skip sanding final clear coat unless recoating again

At Prime, we sand between primer and topcoat layers when finishing custom metal parts, especially those used in high-precision or exposed applications.

Conclusion

Refinishing metal requires proper prep, sanding, and coating—but it makes old parts look and perform like new.

Contact Prime today for expert metal refinishing and coating services. With 20+ years of experience, 10 production lines, and ISO-certified finishes, we restore and supply custom CNC and stamped metal parts ready for industrial use or resale.