Can you sand back metal?

Rough or rusted metal affects part performance and finish adhesion.

Yes, you can sand back metal to remove rust, paint, or surface defects. Use the right tools and technique to avoid damage.

Proper sanding preps the surface for coating or use, making it smoother and safer.

How to sand back metal?

Many surfaces need sanding before coating. Without it, paint peels and rust returns.

To sand back metal, start with coarse grit to remove rust or coatings. Then, use finer grits to smooth and prepare the surface.

Manual sanding or power tools can both be used depending on the part size and condition.

Step-by-Step Metal Sanding Process

- Clean the surface with degreaser

- Use 60–80 grit to remove rust or paint

- Switch to 120–220 grit for smoothing

- Wipe down with a tack cloth

- Finish with 320–400 grit before painting

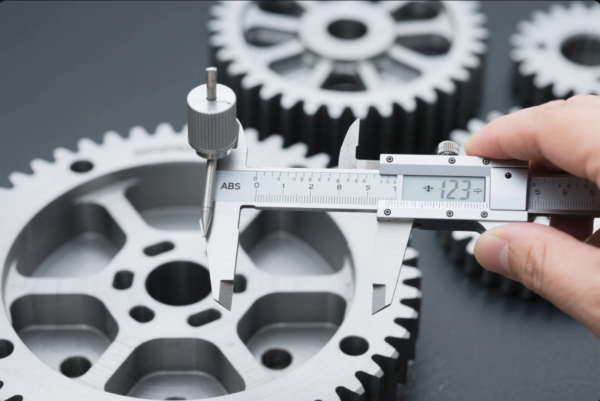

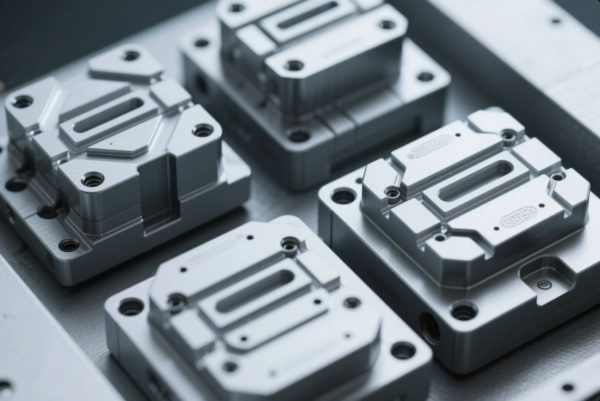

At Prime, our team uses industrial sanders and blast cabinets to prepare custom CNC parts and metal stamping components for coating.

What kind of sandpaper can be used for metal?

The wrong sandpaper wears out fast—or scratches the surface too deeply.

Use aluminum oxide or silicon carbide sandpaper on metal. These types are hard enough to cut through rust and paint.

Choose grit size based on the level of surface damage or smoothness needed.

Sandpaper Types and Uses for Metal

| Sandpaper Type | Best Use Case | Grit Range |

|---|---|---|

| Aluminum Oxide | General sanding, prep | 80–400 |

| Silicon Carbide | Wet sanding, polishing | 400–1000+ |

| Zirconia Alumina | Heavy-duty removal | 36–80 |

At Prime, we match sandpaper type and grit to each metal component—ensuring clean, ready-to-coat parts on every production run.

What happens if you sand metal?

Sanding metal changes its surface—sometimes for better, sometimes for worse.

Sanding removes surface material, exposing clean metal underneath. It improves coating adhesion, removes rust, and can smooth out imperfections.

But aggressive sanding with the wrong grit may cause deep scratches or uneven surfaces.

Effects of Sanding Metal

| Action | Result |

|---|---|

| Light sanding | Smooth finish, good adhesion |

| Coarse sanding | Fast rust removal, surface marks |

| Wet sanding | Ultra-smooth finish, polishing prep |

That’s why at Prime, we control sanding pressure and grit type when finishing ISO-certified metal parts—protecting tolerances and aesthetics.

How to smooth a metal surface?

Sharp edges or rough patches can lead to wear, failure, or safety hazards.

Smooth a metal surface by sanding progressively from coarse to fine grit, then finishing with polishing compound if needed.

For high-precision or decorative parts, wet sanding and buffing give the best results.

Smoothing Process for Metal Surfaces

- Start with 80–120 grit for rough areas

- Move to 220–320 grit to refine texture

- Use 400–600 grit for finishing

- Apply metal polish or buffing wheel if desired

- Wipe clean and seal with coating if needed

At Prime, we smooth and polish CNC parts and casting components before surface treatment—ensuring performance and product appeal.

Conclusion

Yes, metal can be sanded safely with the right technique, grit, and care.

Contact Prime today for expert surface prep, sanding, and industrial coating services. With 20+ years of experience, 10 production lines, and ISO-certified processes, we deliver smooth, clean, ready-to-finish metal components to global industries.