How does a stamping machine work?

Metal parts don’t shape themselves—precision stamping machines do the heavy work.

A stamping machine works by applying controlled force through a die to cut, bend, or shape metal sheets into desired forms.

The process uses mechanical or hydraulic power, depending on the application and part complexity.

How do stamping machines work?

It’s not just about pressure—it’s about control, timing, and alignment.

Stamping machines press a die against a metal sheet using either a mechanical or hydraulic system. The die shapes, cuts, or forms the metal instantly.

Each press cycle can produce one or more finished components.

Basic Stamping Machine Operation

| Component | Role |

|---|---|

| Press Frame | Holds the working components |

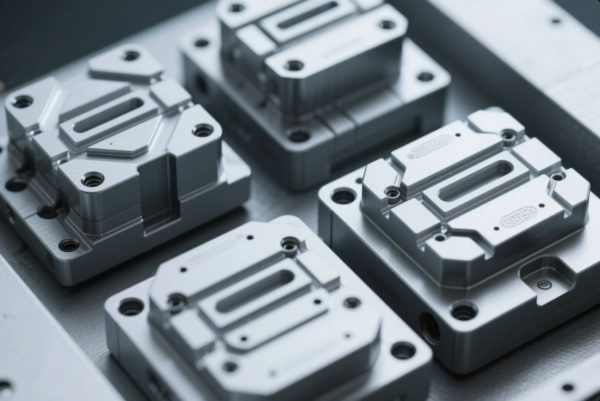

| Die Set | Shapes or cuts the metal |

| Ram (Slide) | Moves the die with force |

| Bolster Plate | Supports the workpiece |

| Power Source | Mechanical, hydraulic, or servo |

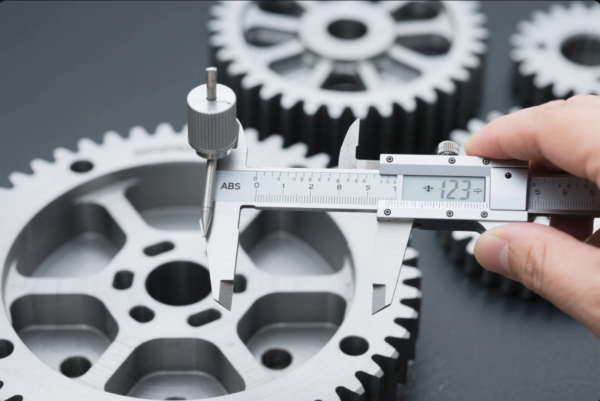

At Prime, our stamping lines use both high-speed and precision stamping presses to manufacture custom metal parts with tight tolerances.

What is the mechanical process of stamping?

Behind every clean-cut part is a well-timed mechanical movement.

The mechanical stamping process involves a rotating flywheel, crankshaft, and connecting rod that convert rotary motion into vertical force.

This delivers fast, repetitive cycles—ideal for high-volume production.

Mechanical Stamping in Action

- Flywheel rotates using an electric motor

- Clutch engages the flywheel with the crankshaft

- Crankshaft drives ram up and down

- Die presses metal to cut or form the shape

- Part ejects and cycle repeats

We rely on mechanical stamping at Prime for medium to high-volume stamping parts, such as brackets, flanges, and fasteners.

How does the stamping process work?

Stamping is fast—but it’s also precise, involving multiple steps in one machine cycle.

The stamping process uses a combination of forming techniques—blanking, piercing, bending, or drawing—to shape raw sheet metal into finished parts.

The tool design determines which operations occur in each stroke.

Key Stamping Techniques

| Technique | Function | Common Use |

|---|---|---|

| Blanking | Cuts flat shape from sheet | Component outline |

| Piercing | Punches holes | Bolt holes, fastener points |

| Bending | Creates angled forms | Brackets, enclosures |

| Drawing | Forms deep shapes from flat sheet | Pans, containers |

At Prime, we use progressive dies to combine steps into one cycle—speeding up production and reducing waste on custom stamped components.

What are the 7 steps in the stamping method?

Each stamped part follows a defined path from flat sheet to functional shape.

The 7 standard steps in metal stamping include: blanking, piercing, bending, forming, drawing, trimming, and coining.

These can be done separately or combined in a progressive die setup.

The 7 Steps in Metal Stamping

| Step | Description |

|---|---|

| Blanking | Cuts flat piece from sheet |

| Piercing | Punches holes or cutouts |

| Bending | Forms angles or curves |

| Forming | Applies shape without removing material |

| Drawing | Deeply stretches material into cavities |

| Trimming | Removes excess or unwanted edges |

| Coining | Applies fine detail under high pressure |

At Prime, we streamline these steps through progressive die stamping to manufacture ISO-certified metal parts faster and more efficiently.

Conclusion

Stamping machines use precise force and tooling to shape, bend, and cut metal sheets into finished parts—quickly and accurately.

Contact Prime today for expert stamping services, fast lead times, and high-volume production. With 20+ years of experience, 10 advanced stamping lines, and ISO-certified quality, we deliver custom metal parts built for global industrial use.