What is the process of forming and stamping?

Raw metal sheets need force and accuracy to become usable parts.

Forming and stamping are industrial processes that shape flat metal sheets into precise components using mechanical or hydraulic presses and custom dies.

These methods are fast, repeatable, and ideal for high-volume manufacturing.

What is the process of stamping and forming?

One cuts and shapes; the other bends and stretches—together, they complete the part.

Stamping includes cutting, piercing, and forming actions; forming focuses on reshaping metal without cutting. Both are done using press machines and dies.

The combination ensures clean edges, tight angles, and detailed shapes.

Key Phases in Stamping and Forming

| Phase | Purpose |

|---|---|

| Material Feeding | Sheet metal loaded into the press |

| Die Alignment | Sheet positioned under the tooling |

| Cutting Action | Shapes material via blanking/piercing |

| Forming Operation | Applies force to bend, stretch, or draw |

| Part Ejection | Finished component exits the die |

At Prime, we integrate stamping and forming using progressive dies and servo-driven presses, ensuring efficient production of custom metal parts.

What is the stamping procedure?

Stamping isn’t a single hit—it’s a full cycle with precise steps.

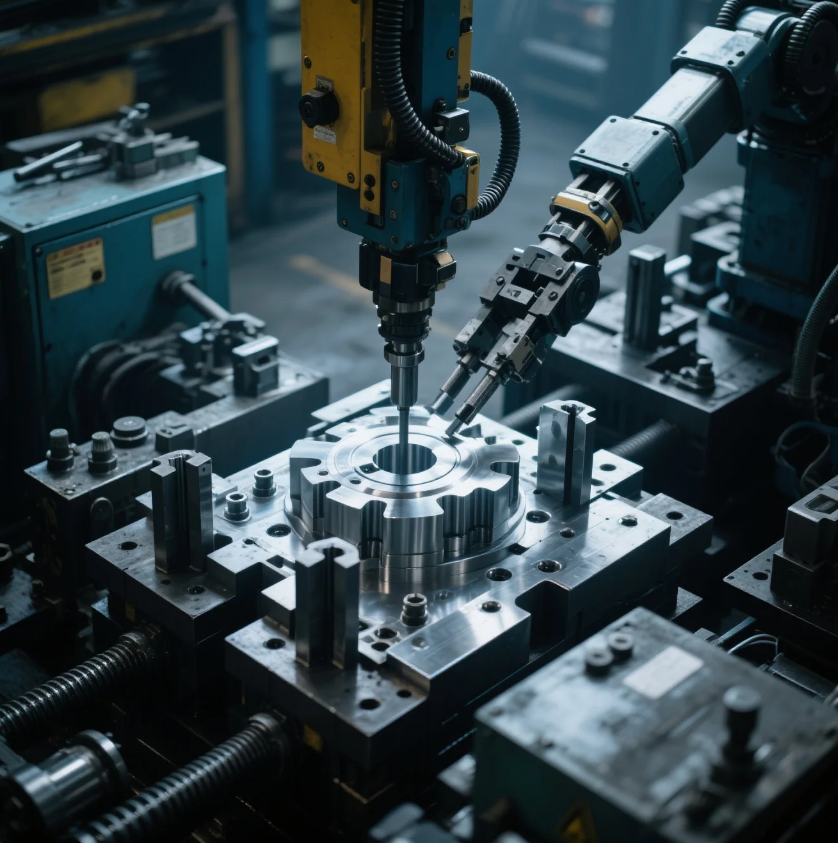

The stamping procedure involves feeding metal into a press, aligning it with a die, and using pressure to shape or cut the material.

This cycle runs continuously to produce large quantities quickly.

Stamping Procedure Breakdown

- Material uncoiling or feeding

- Positioning and die closing

- Punching, blanking, or bending action

- Finished part removal or ejection

- Repeat for next part

We automate this sequence at Prime using high-speed feeders, die sensors, and precision tooling—ensuring consistent results for ISO-certified stamping parts.

What are the steps in stamping method?

Each step in stamping transforms the sheet into something functional.

The stamping method consists of a series of operations like blanking, piercing, bending, forming, drawing, trimming, and coining.

These steps can be combined in one tool or done across multiple stations.

The 7 Steps of Stamping

| Step | Function |

|---|---|

| Blanking | Cuts raw sheet into usable shapes |

| Piercing | Adds holes or slots |

| Bending | Forms metal into angles or corners |

| Forming | Shapes curves or contours |

| Drawing | Stretches material into deep cavities |

| Trimming | Removes excess or sharp edges |

| Coining | Stamps logos, ridges, or fine detail |

Our 10 production lines at Prime handle these steps seamlessly, producing high-precision stamping parts for automotive, electronics, and industrial applications.

What is the process of making a stamp?

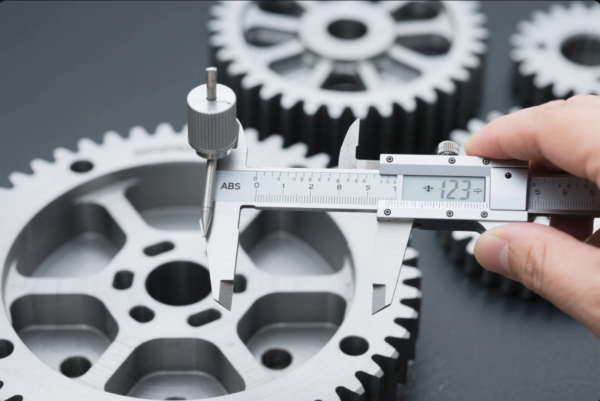

Before stamping can begin, the right tooling must be created.

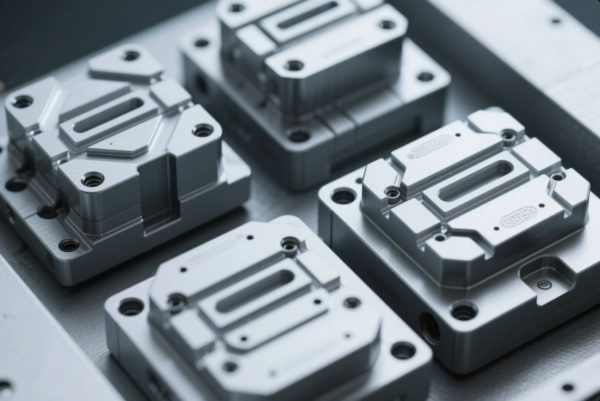

Making a stamp (or stamping die) involves designing, machining, and testing a custom tool that fits inside a press to shape metal.

This die determines the part’s dimensions, features, and tolerances.

Steps in Die-Making for Stamping

| Step | Description |

|---|---|

| CAD Design | Part and tooling modeled digitally |

| CNC Machining | Die block cut from tool steel |

| Heat Treatment | Hardens die for long life |

| Assembly & Testing | Aligned and checked in press |

| Production Start | Stamp runs begin using final tooling |

At Prime, we design and manufacture our own dies—guaranteeing accuracy and quick lead times for all custom-stamped components.

Conclusion

Forming and stamping transform flat metal into precise, functional parts through a series of cutting, shaping, and pressing steps.

Contact Prime today for expert stamping solutions, in-house die design, and global delivery. With over 20 years of experience, 10 production lines, and ISO-certified processes, we deliver reliable, high-volume custom metal parts for industrial clients worldwide.