How do you find the size of a bolt for a nut?

Using the wrong bolt size leads to stripped threads, loose connections, or system failure.

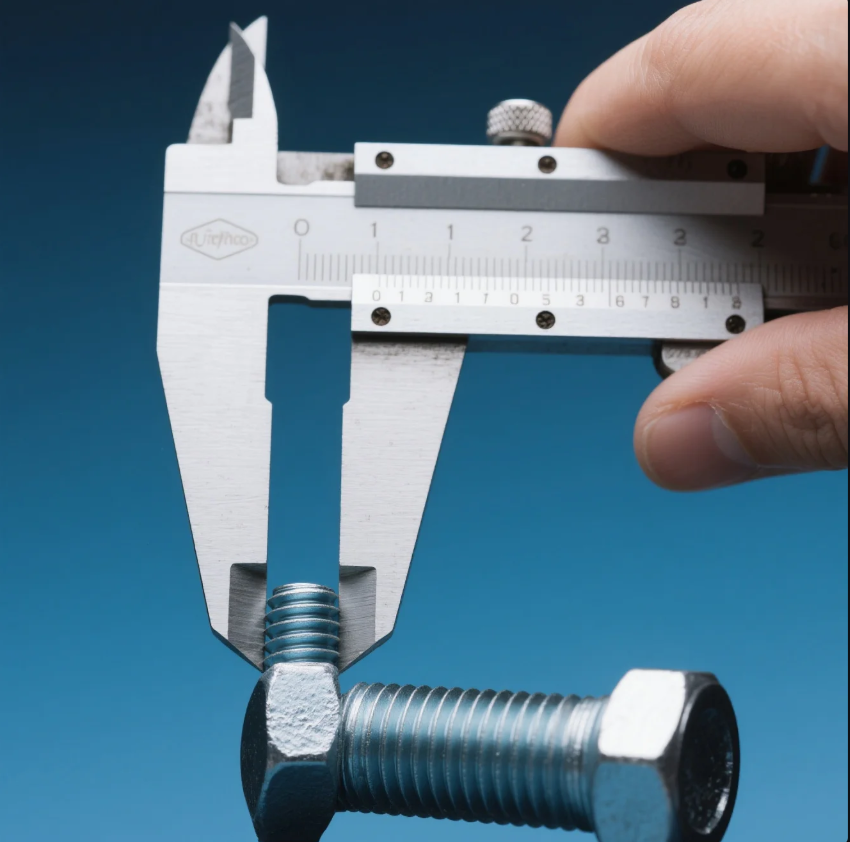

To find the correct bolt size for a nut, measure thread diameter, pitch, and length. Use calipers and thread gauges for accuracy. Matching bolt and nut size ensures safety and mechanical performance.

Guesswork doesn’t work when selecting fasteners. Let’s walk through how professionals size bolts—and how Prime delivers ready-to-fit, ISO-certified bolts for your exact needs.

How to identify nut bolt size?

You can’t identify size just by looking. You need tools and numbers.

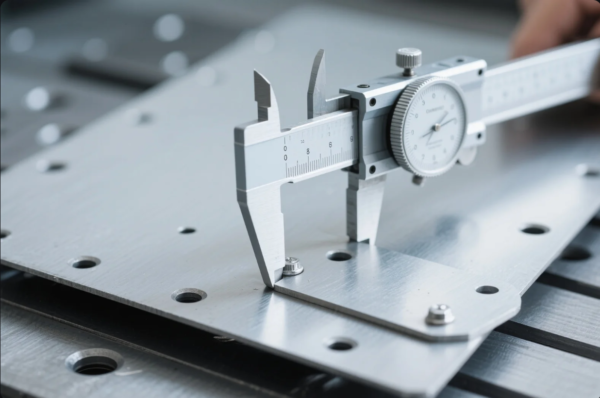

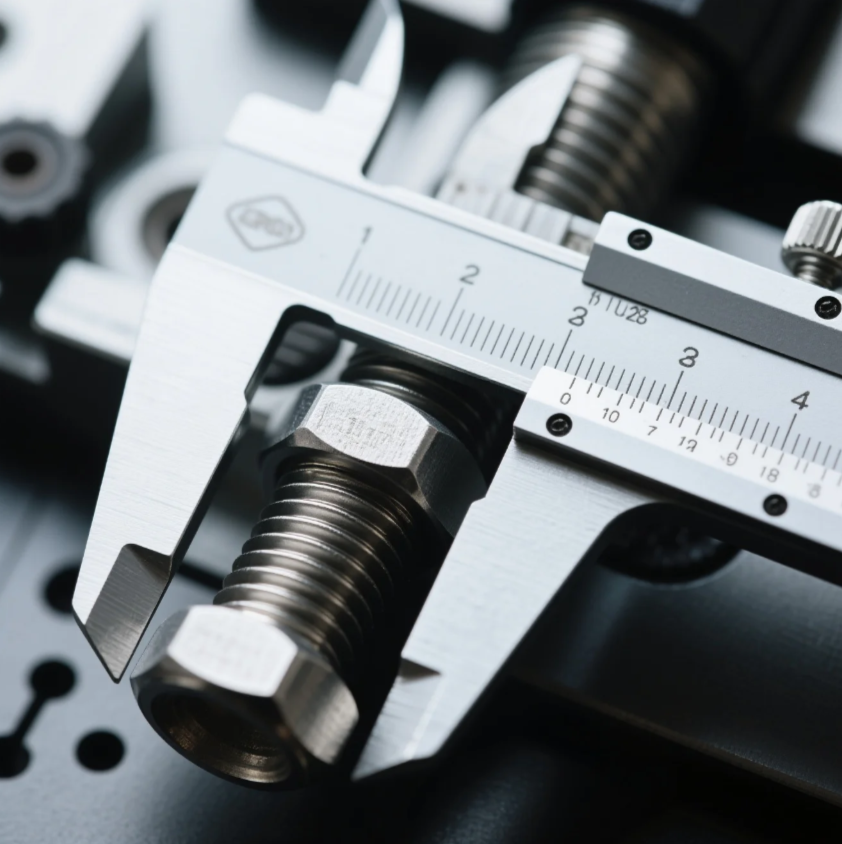

To identify nut and bolt size, measure the bolt’s major diameter and thread pitch. Use a caliper and thread gauge.

Start with the outer diameter. Then check the thread pitch (distance between threads). Finally, measure the length under the head to the tip. Prime labels all bolts with clearly marked specs for fast identification.

Key Bolt Size Measurements

| Measurement | Tool Needed | What It Tells You |

|---|---|---|

| Diameter | Caliper | Bolt size (e.g. M8, 3/8") |

| Thread Pitch | Thread gauge | Metric or UNC/UNF thread |

| Bolt Length | Ruler or caliper | Needed depth for assembly |

Once, a client used an M10 nut on an M10x1.0 fine thread bolt by mistake. It didn’t fit. Now, they order Prime’s custom-labeled fastener kits, sorted by size and pitch.

How do you match bolt and nut size?

Not all bolts fit all nuts—even if they look close in size.

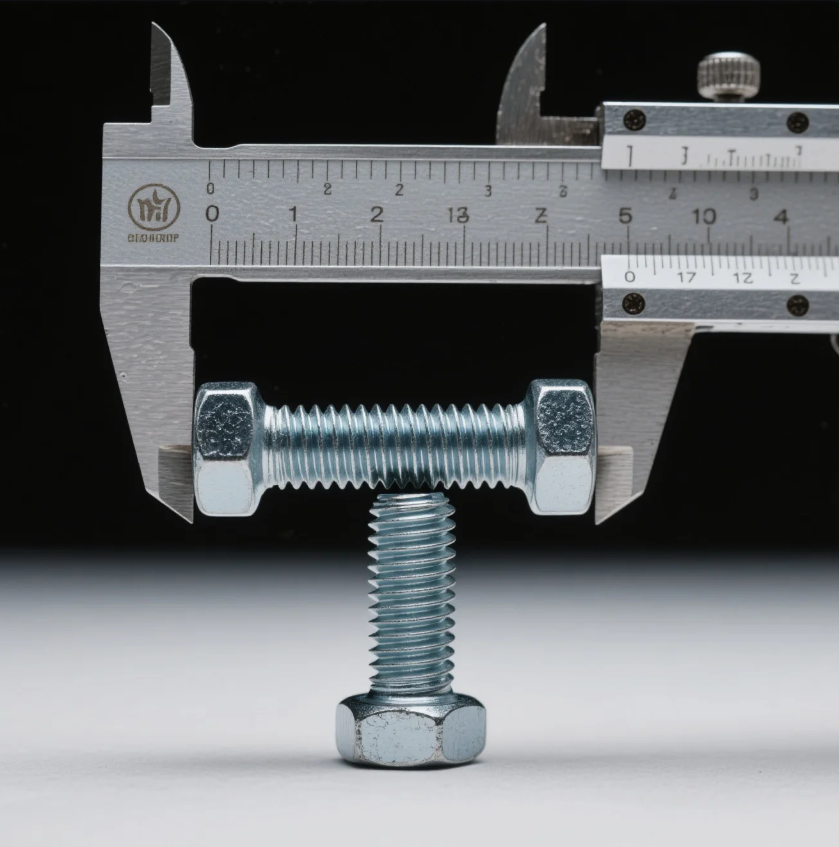

You match bolt and nut size by ensuring the thread diameter, pitch, and standard (metric or imperial) are identical.

Mismatched threads strip or jam. Always check for correct threading and tolerance. At Prime, every bolt and nut set is matched and tested before shipment.

Matching Nut and Bolt Checklist

- Confirm both are metric or both are imperial

- Match the thread diameter (e.g., M10 or 3/8”)

- Match thread pitch (e.g., 1.5mm or 16 TPI)

- Match grade and material where necessary

We supply many OEMs with pre-assembled nut-and-bolt kits. This saves their engineers time and ensures assembly line precision.

How do you find the correct size of a bolt?

Start with your design needs—then size your bolt accordingly.

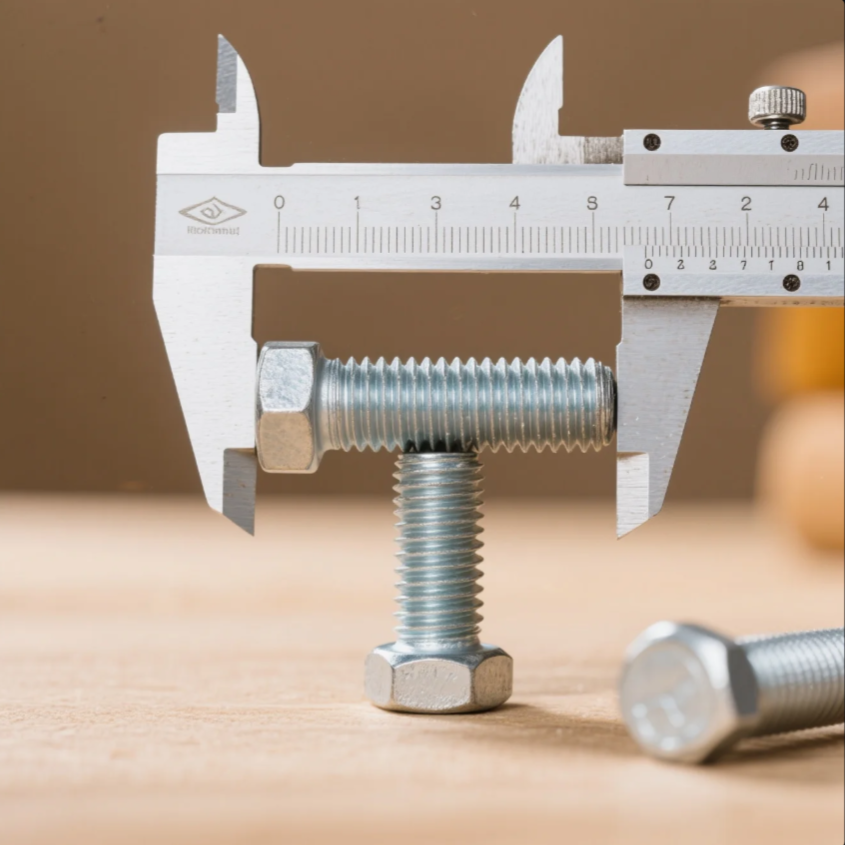

To find the correct bolt size, consider load strength, hole diameter, material thickness, and environmental exposure. Use engineering charts or standards.

In structural or moving parts, bolt failure is dangerous. We help clients choose based on shear, tension, and torque requirements.

Factors That Determine Bolt Size

| Factor | Why It Matters |

|---|---|

| Load Type | Affects diameter & grade |

| Hole Diameter | Sets the outer thread size |

| Material Thickness | Affects length |

| Vibration/Environment | Affects coating and threading |

One of our solar power clients used undersized bolts early on. They failed under wind load. We helped them upgrade to ISO-grade M12 bolts with hot-dip galvanizing. Since then—zero failures.

How do I determine what bolt size I need?

It depends on where and how you’ll use the bolt. Don't copy-paste from old projects.

You determine bolt size by evaluating design requirements and measuring the hole it must pass through. Factor in the application’s mechanical and environmental conditions.

Don't rely on eye estimates. Use calipers, bolt sizing charts, or consult with your supplier. Prime helps customers select the exact bolt dimensions and coating for their project, including load documentation and CAD drawings.

Steps to Determine Bolt Size

-

Measure the hole diameter

Use a digital caliper for precision. -

Decide the bolt length

Add washer and nut thickness if needed. -

Choose thread type

Metric vs. imperial; coarse vs. fine. -

Check load requirements

Look up standard torque and stress ratings. -

Select coating or treatment

Based on environment (corrosive, high-temp, etc.)

Our engineering team often works directly with client CAD drawings. We supply custom CNC bolts, stamping parts, and fasteners based on the specs—ready for immediate installation.

Conclusion

To match a bolt with a nut, measure accurately and select by thread, size, and application need.

Need perfectly matched bolts and nuts? Contact Prime today for a free consultation and quote. We deliver custom fastener kits, CNC parts, and ISO-certified bolt solutions—pre-sorted, pre-tested, and ready for your next project.